Method for preparing forage grass from complex leavening agent and biological yellow corn silage of yellow corn straw

A compound fermentation agent and straw biological technology, which is applied in the field of biological agriculture, can solve the problems of high crude fiber content, poor palatability, and difficulty in uniform enzymatic hydrolysis, and achieve high protein and sugar content, increased protein content, and improved digestion and utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment one, the preparation of composite starter: 20 parts of cellulase, 15 parts of ligninase, 8 parts of protease, 5 parts of lipase, 5 parts of pectinase, 5 parts of Trichoderma viride liquid, 8 parts of lactic acid bacteria liquid, yeast 8 parts of bacteria liquid, 8 parts of urea.

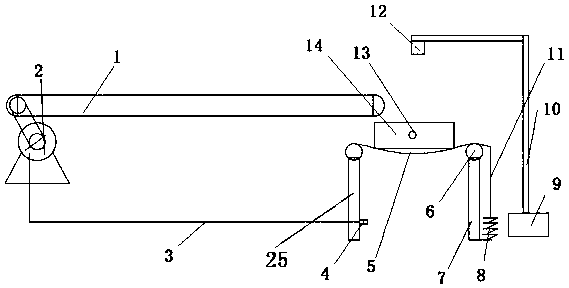

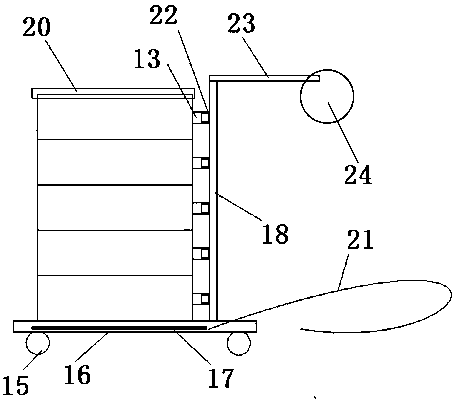

[0067] Preparation: Knead corn yellow stalks in a silk kneading machine and process them into corn yellow stalk silk;

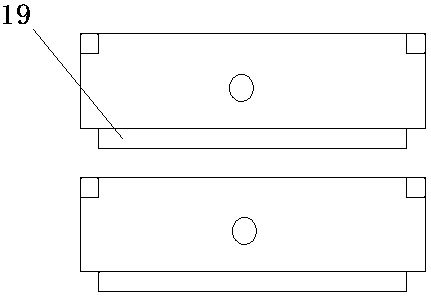

[0068] Biological enzymatic hydrolysis and fermentation: Spray the compound preparation on the yellow corn stalk silk according to the addition amount of 4%, adjust the water content to 40%W / W, put it in a closed plastic bag or store it in the cellar and compact it, and start at natural temperature After 30 days of fermentation, corn yellow stalks can be fermented forage, which can be sealed and stored for a long time.

[0069] The soluble carbohydrates in the obtained forage grass were reduced by 48%, the crude protein content was 20%, and the acidity was reduced...

Embodiment 2

[0070] Embodiment two, the preparation of composite starter: 15 parts of cellulase, 18 parts of ligninase, 10 parts of protease, 6 parts of lipase, 6 parts of pectinase, 6 parts of Trichoderma viride liquid, 10 parts of lactic acid bacteria liquid, yeast 10 parts of bacteria liquid, 9 parts of urea.

[0071] Preparation: Knead corn yellow stalks in a silk kneading machine and process them into corn yellow stalk silk;

[0072] Biological enzymatic hydrolysis and fermentation: Spray the compound preparation on the yellow corn stalk silk according to the addition amount of 4%, adjust the water content to 50% W / W, put it in a closed plastic bag or store it in the cellar and compact it, and start at natural temperature After 45 days of fermentation, corn yellow stalks can be fermented forage, which can be sealed and stored for a long time.

[0073] The soluble carbohydrates in the obtained forage are reduced by 50%, the crude protein content is 22%, and the acidity is reduced to 4...

Embodiment 3

[0074] Embodiment three, the preparation of composite starter: 30 parts of cellulase, 20 parts of ligninase, 12 parts of protease, 8 parts of lipase, 8 parts of pectinase, 8 parts of Trichoderma viride liquid, 12 parts of lactic acid bacteria liquid, yeast 12 parts of bacteria liquid, 10 parts of urea.

[0075] Preparation: Knead corn yellow stalks in a silk kneading machine and process them into corn yellow stalk silk;

[0076] Biological enzymatic hydrolysis and fermentation: Spray the compound preparation on the yellow corn stalk silk according to the addition amount of 4%, adjust the water content to 60% W / W, put it in an airtight plastic bag or store it in the cellar and compact it, and start at natural temperature After 60 days of fermentation, the corn yellow stalks can be fermented forage, which can be stored in a sealed form for a long time.

[0077] The soluble carbohydrates in the obtained forage grass were reduced by 52%, the crude protein content was 25%, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com