Method for treating dye wastewater through cooperation of adsorption and magnetization separation technologies

A dye wastewater and separation technology technology, which is applied in the field of dye wastewater treatment by adsorption synergistic magnetization separation technology, can solve problems affecting human health and normal life, environmental loss, biological life activities, etc., and achieve stability and recycling performance. , Prevent secondary pollution, good adsorption and removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

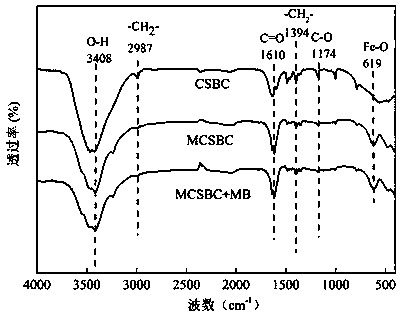

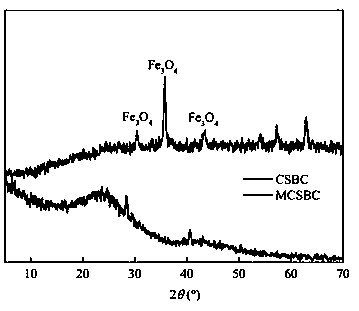

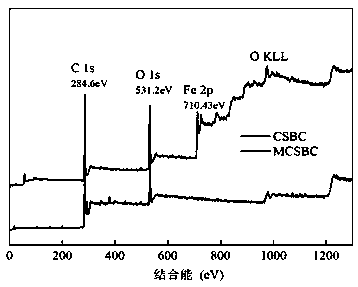

[0033] Preparation of biochar

[0034] Preparation of raw biochar: Soak cotton stalks in water to remove surface impurities, dry and crush them, pass the debris through a 40-mesh sieve, put them into a crucible, and place them in a muffle furnace for high-temperature pyrolysis at a temperature of 500 °C , after pyrolysis for 6 h, take it out, cool to room temperature, take out the carbonized product and grind it into powder, and pass through an 80-mesh sieve. Then pickle repeatedly with hydrochloric acid to remove ash, and then rinse repeatedly with deionized water until the carbonized product is neutral, place it in an oven at 80°C for drying, take it out after 12 hours, cool it to room temperature, and put it into a brown bottle for use , labeled CSBC.

[0035] Preparation of magnetized modified biochar: Weigh 5.18 g FeSO 4 ·7H 2 O and 4.16 g FeCl 3 ·6H 2 O was dissolved in 50 mL of ultrapure water, and after stirring evenly, 5 g of the prepared CSBC was added, and afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com