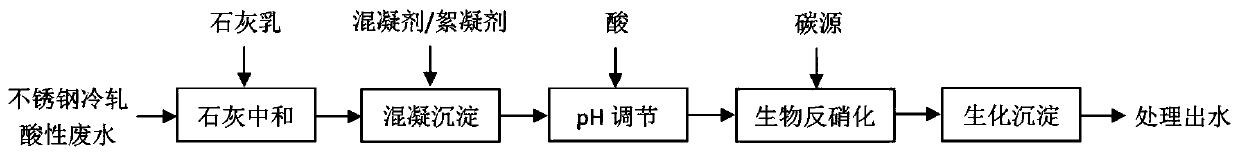

Stainless steel cold-rolled acid wastewater denitrification treatment process

A technology of acid wastewater and treatment process, which is applied in the field of water treatment, can solve the problems of high cost of wastewater treatment chemicals, and achieve the effect of solving the high cost of wastewater treatment chemicals, saving costs, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

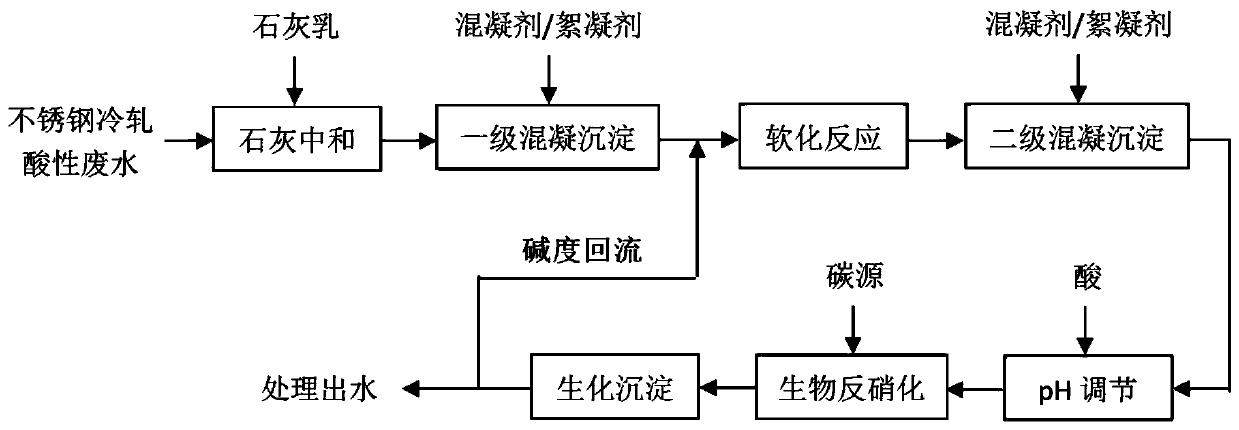

[0032] A stainless steel cold rolling acid waste water denitrification process, please refer to figure 2 , which includes the following steps:

[0033] 1) Lime neutralization: add milk of lime (5-10% mass concentration) to stainless steel cold-rolled acid wastewater for lime neutralization treatment, and the hydraulic retention time is 0.5h; through lime neutralization treatment, fluoride ions, Sulfate ions react with calcium ions to form calcium fluoride and calcium sulfate precipitates. At the same time, heavy metal ions such as iron, nickel, and chromium in wastewater form hydroxide precipitates under alkaline conditions;

[0034] 2) Primary coagulation and sedimentation: add coagulants and flocculants in turn to the effluent after step 1) lime neutralization for coagulation and sedimentation, the hydraulic retention time is 0.3h; and the produced insoluble matter to form larger dense flocs, and then the sedimentation sludge (that is, dense flocs) is separated from water ...

Embodiment 2

[0042] A stainless steel cold rolling acid waste water denitrification process, please refer to figure 2 , which includes the following steps:

[0043] 1) Lime neutralization: lime milk (5-10% mass concentration) is added to stainless steel cold rolling acid wastewater for lime neutralization treatment, and the hydraulic retention time is 1h; through lime neutralization treatment, fluoride ions and sulfuric acid in wastewater Root ions react with calcium ions to form precipitates of calcium fluoride and calcium sulfate. At the same time, heavy metal ions such as iron, nickel, and chromium in wastewater form hydroxide precipitates under alkaline conditions;

[0044] 2) Primary coagulation and sedimentation: add coagulant and flocculant in sequence to the effluent after lime neutralization in step 1) for coagulation and sedimentation, and the hydraulic retention time is 0.5h; and the produced insoluble matter to form larger dense flocs, and then the sedimentation sludge (that ...

Embodiment 3

[0052] A stainless steel cold rolling acid waste water denitrification process, reference figure 2 , which includes the following steps:

[0053] 1) Lime neutralization: transport the stainless steel cold rolling acid wastewater to the lime neutralization tank, add lime milk (5-10% mass concentration) to the stainless steel cold rolling acid wastewater for lime neutralization treatment; the lime neutralization tank , the hydraulic retention time is 0.5-1h; through lime neutralization treatment, the pH value of the wastewater is adjusted to 9.5-10.5, and the fluoride ions and sulfate ions in the wastewater react with calcium ions to form calcium fluoride and calcium sulfate precipitation. At the same time, the wastewater Iron, nickel, chromium and other heavy metal ions in the solution form hydroxide precipitates under alkaline conditions;

[0054] 2) Primary coagulation and sedimentation: transport the effluent after step 1) lime neutralization to the primary coagulation tan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com