A fast-firing polymorph multi-color crystalline glaze and its preparation method and application

A multi-color, crystalline glaze technology, applied in the preparation of fast-firing polymorphic multi-color crystalline glaze ceramic products, fast-firing polymorphic multi-color crystalline glaze and its preparation, fast-firing polymorphic multi-color crystalline glaze ceramic products In the field of high-temperature firing, it can solve the problems of poor thixotropy and fluidity of glaze paste, poor thermal stability of crystalline glaze, overcast and smoked glaze layer, and achieve the effect of avoiding easy-flowing glaze, good thermal stability and improving fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

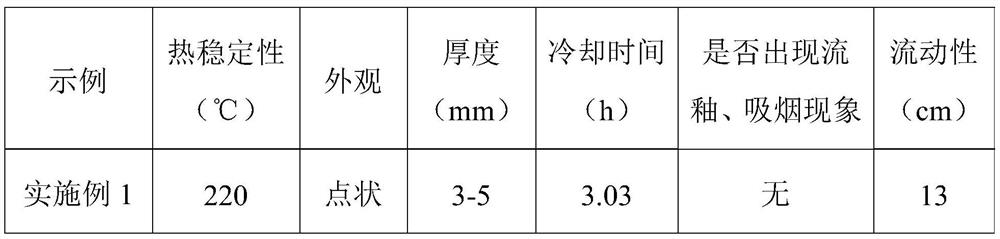

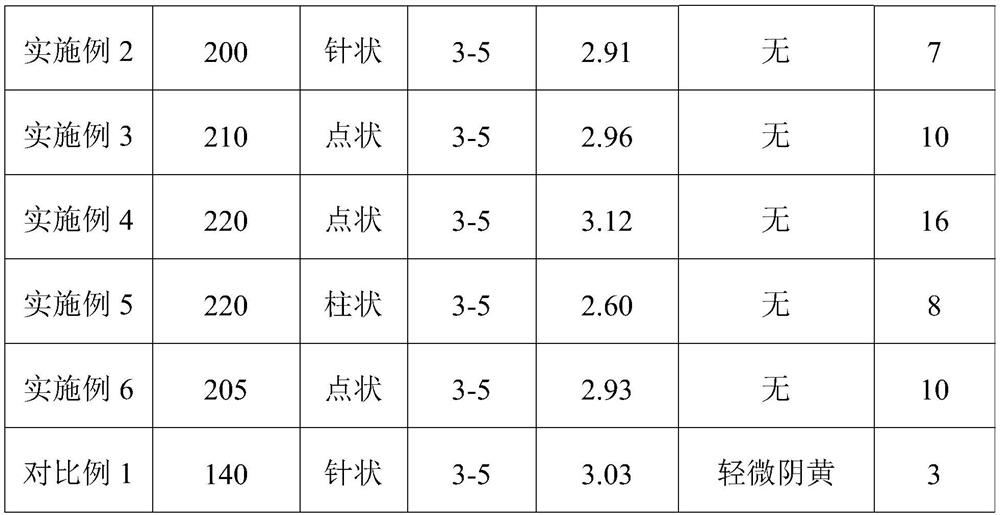

Examples

Embodiment 1

[0026] This embodiment provides a fast-firing polymorph multi-color crystalline glaze, which is composed of: 15 parts of calcined zinc oxide, 10 parts of calcined titanium oxide, 15 parts of calcined light calcium carbonate, 15 parts of calcined light magnesium carbonate, long 30 parts of stone, 8 parts of kaolin, 7 parts of quartz and 1.5 parts of cobalt oxide;

[0027] The preparation and sintering method of above-mentioned crystalline glaze are,

[0028] Mix the above raw materials evenly, put them into a ball mill, then add water for ball milling, pass through a 180-mesh sieve, add water to adjust the water content of the glaze to 45%, and obtain the finished glaze slurry;

[0029] Take the green body and apply the glaze by dipping the glaze. The thickness of the glaze layer is controlled at 3-5mm. Under 0.01MPa, the temperature is raised from room temperature to 300°C for 3.5h; The time is 1h, the pressure of this process is 0.025MPa; then the temperature is raised to 11...

Embodiment 2

[0031] This embodiment provides a fast-firing polymorph multi-color crystal glaze, which is composed of: 15 parts of calcined zinc oxide, 10 parts of calcined titanium oxide, 15 parts of calcined light calcium carbonate, 20 parts of calcined light magnesium carbonate, long 20 parts of stone, 8 parts of kaolin, 7 parts of quartz, 0.8 parts of iron oxide;

[0032] The preparation and sintering method of above-mentioned crystalline glaze are,

[0033] Mix the above raw materials evenly, put them into a ball mill, then add water for ball milling, pass through a 180-mesh sieve, add water to adjust the water content of the glaze to 45%, and obtain the finished glaze slurry;

[0034]Take the green body and apply the glaze by blowing the glaze. The thickness of the glaze layer is controlled at 3-5mm. Then, under 0.015MPa, the temperature is raised from room temperature to 320°C for 4 hours; then the temperature is raised to 845°C, and the temperature is raised The time is 1.5h, the p...

Embodiment 3

[0036] This embodiment provides a fast-firing polymorph multicolor crystalline glaze, which is composed of: 20 parts of calcined zinc oxide, 5 parts of calcined titanium oxide, 20 parts of calcined light calcium carbonate, 10 parts of calcined light magnesium carbonate, long 25 parts of stone, 8 parts of kaolin, 7 parts of quartz, 0.8 part of cobalt oxide and 0.2 part of iron oxide;

[0037] The preparation and sintering method of above-mentioned crystalline glaze are,

[0038] Mix the above raw materials evenly, put them into a ball mill, then add water for ball milling, pass through a 180-mesh sieve, add water to adjust the water content of the glaze to 45%, and obtain a finished glaze slurry;

[0039] Take the green body and apply the glaze by dipping the glaze. The thickness of the glaze layer is controlled at 3-5mm. Under 0.01MPa, the temperature is raised from room temperature to 298°C for 3 hours; then the temperature is raised to 875°C and the heating time is 1.2h, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com