Preparation method of SiC fiber-reinforced SiC ceramic-based parts and product

A fiber-reinforced, ceramic-based technology, applied in the field of SiC ceramic-based parts preparation, can solve the problems of insufficient density and strength of parts, high melting temperature of ceramics, and large stress of parts, so as to achieve structure and performance improvement, high SiC content, The effect of structure and performance optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

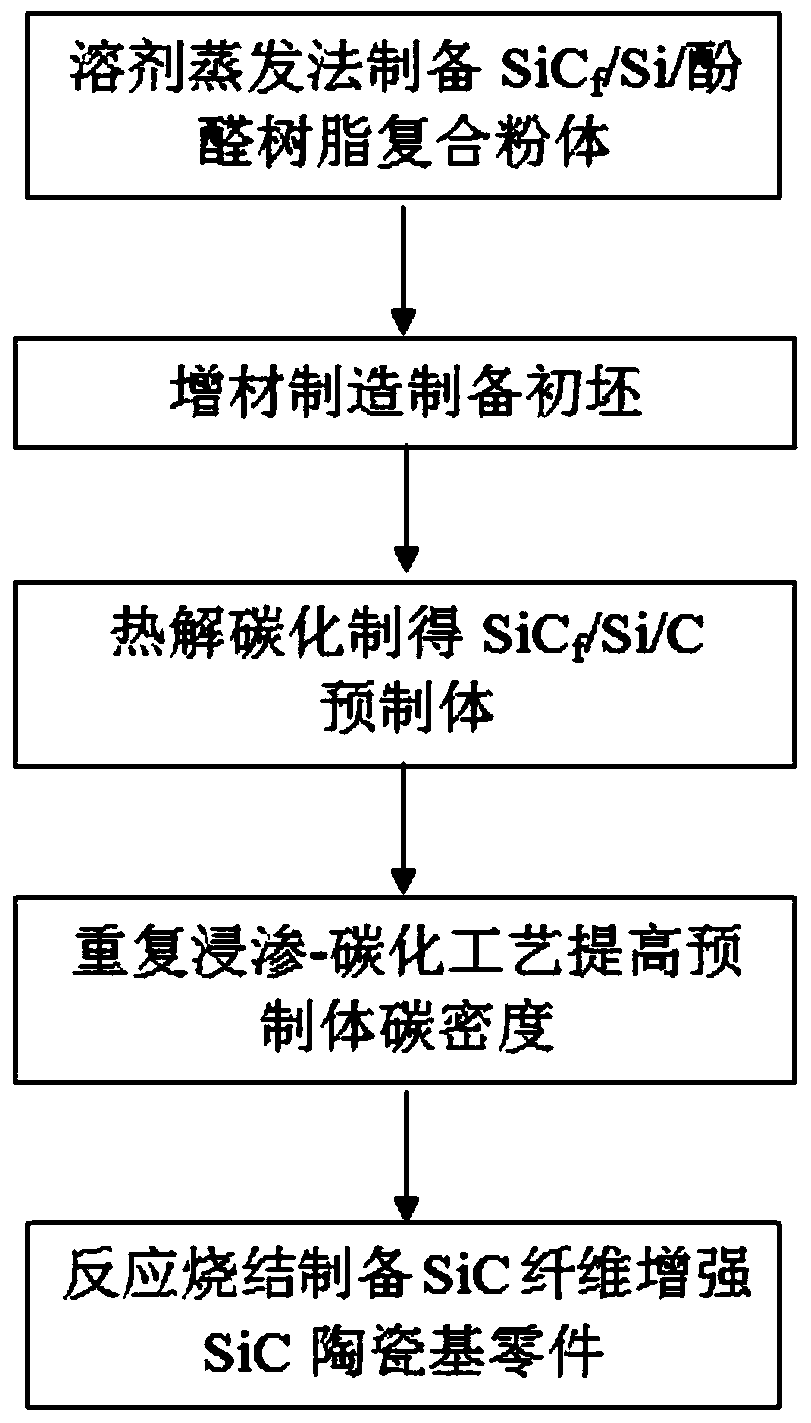

[0032] Such as figure 1 Shown, a kind of preparation method and product thereof of SiC fiber reinforced SiC ceramic base parts, this method comprises the following steps:

[0033] (a) Preparation of SiC by solvent evaporation method f / Si / phenolic resin composite powder;

[0034] (a1) Add Si powder and SiC fiber after the thermoplastic phenolic resin is completely dissolved in an organic solvent to obtain the SiC f / Si / phenolic resin uniformly dispersed solution, in which SiC f is SiC fiber;

[0035] (a2) Distill the solution to obtain powder aggregates, and dry, grind and sieve to obtain the SiC f / Si / phenolic resin composite powder;

[0036] In step (a1), the particle size of the Si powder is 1-30 microns; the diameter of the SiC fiber is 5-30 microns, and the length is 10-200 microns; the thermoplastic phenolic resin, silicon powder and carbonized The volume fraction ratio of the silicon fiber is 1-10:1-3:1-10, and the composite powder prepared in this ratio can meet...

Embodiment 1

[0052] (1) The phenolic resin powder is completely dissolved in the acetone solution at a weight ratio of 1:1;

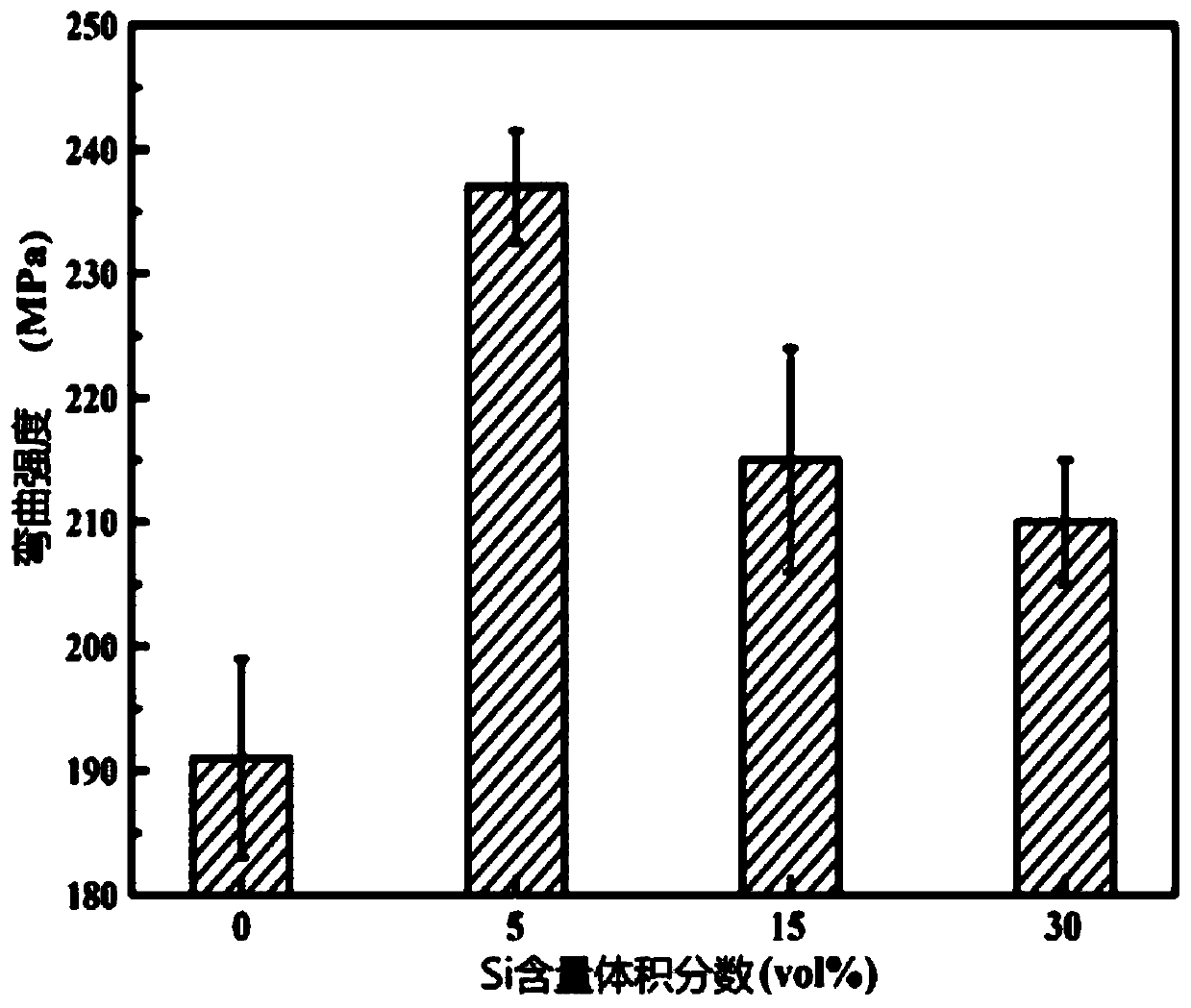

[0053] (2) Add silicon powder and SiC fiber powder to the above solution, and mix uniformly to obtain a mixed solution. The particle size of Si powder is 1-30 microns, the diameter of SiC fiber is 5-30 microns, and the length is 10-200 microns. The volume fraction ratio of thermoplastic phenolic resin, silicon powder and silicon carbide fiber is 1:1:10, and the mixed solution is dried, ground, and sieved to obtain a composite material with a particle size of 10-150 microns;

[0054] (3) Laser selective melting technology is used to form parts according to the part model.

[0055] (4) Carbonize the molded part at 900°C and keep it warm for 1h.

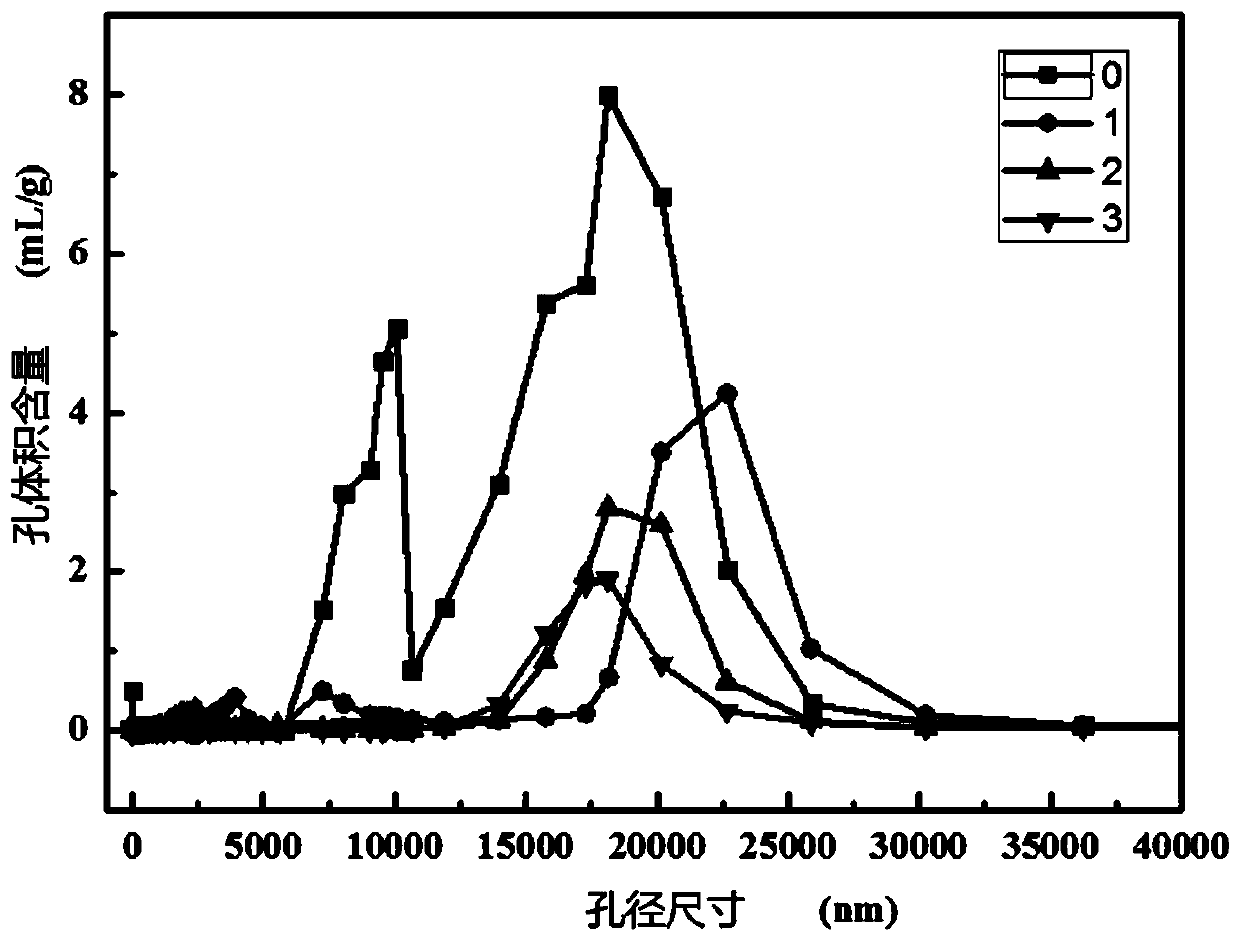

[0056] (5) Immerse the carbonized parts in a thermosetting phenolic resin solution with a residual carbon rate of 40-50%, dry at 80°C for half an hour, and then perform a step curing process: 120°C, 1h; 150°C, 1h; 180°C, 3h....

Embodiment 2

[0060] (1) The phenolic resin powder is completely dissolved in the acetone solution at a weight ratio of 1:1;

[0061] (2) Add silicon powder and SiC fiber powder to the above solution, and mix uniformly to obtain a mixed solution. The particle size of Si powder is 1-30 microns, the diameter of SiC fiber is 5-30 microns, and the length is 10-200 microns. The volume fraction ratio of thermoplastic phenolic resin, silicon powder and silicon carbide fiber is 1:3:1, and the mixed solution is dried, ground, and sieved to obtain a composite material with a particle size of 10-150 microns;

[0062] (3) Laser selective melting technology is used to form parts according to the part model.

[0063] (4) Carbonize the molded part at 900°C and keep it warm for 1h.

[0064] (5) Immerse the carbonized parts in a phenolic resin solution with a residual carbon rate of 40-50%, dry at 80°C for half an hour, and then perform a step curing process: 120°C, 1h; 150°C, 1h; 180°C, 3h. After complet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com