A grinding method for high-quality synthetic mica

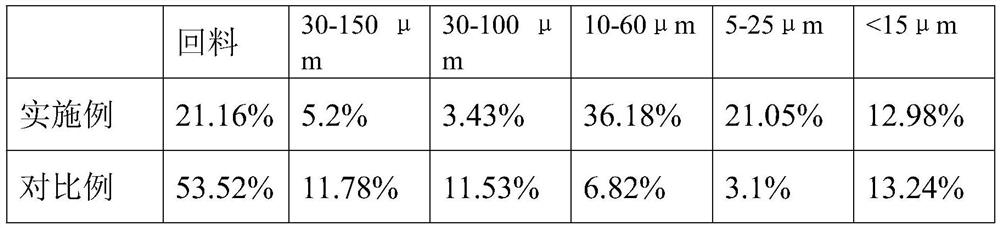

A technology for synthesizing mica and grinding methods, applied in chemical instruments and methods, fibrous fillers, dyeing physical treatment, etc., can solve the problems of many fine powders, poor diameter-to-thickness ratio, and low yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] A grinding method for high-quality synthetic mica, comprising the following steps:

[0030] a. Crushing: The mica fragments are crushed into 200-2000μm mica flakes by ultra-high pressure water; the water pressure of ultra-high pressure water is 6-12Mpa.

[0031] b. Separation: Put the mica flakes into the centrifuge for solid-liquid separation, and dry the water;

[0032] c. Grinding: select grinding equipment, put in grinding media or grinding aids, put in mica flakes, control moisture, and grind for 3-8 hours to form mica powder for pulping and unloading; the grinding equipment is a stirring mill, and the stirring mill The speed of the machine is 50-120, the grinding medium is 10x10mm, 7.5x7.5mm, 5x5mm zirconium beads / columns, the grinding aid is 0.01%-0.05% of mica mass sodium hexametaphosphate, 0.01%-mica mass 0.05% sodium carbonate and 0.01%-0.03% sodium hydroxide of mica mass, grind to control the water content to 25%-40%, and measure it with a moisture analyzer....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com