Method for cooperatively repairing chromium polluted soil by biochar-based zero valent iron and microorganism

A technology for synergistic restoration of chromium-contaminated soil, applied in the field of biochar-based zero-valent iron and microorganisms for synergistic restoration of chromium-contaminated soil, can solve problems such as easy agglomeration and oxidation, and achieve the effects of improving dispersibility, enhancing activity, and speeding up renewal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

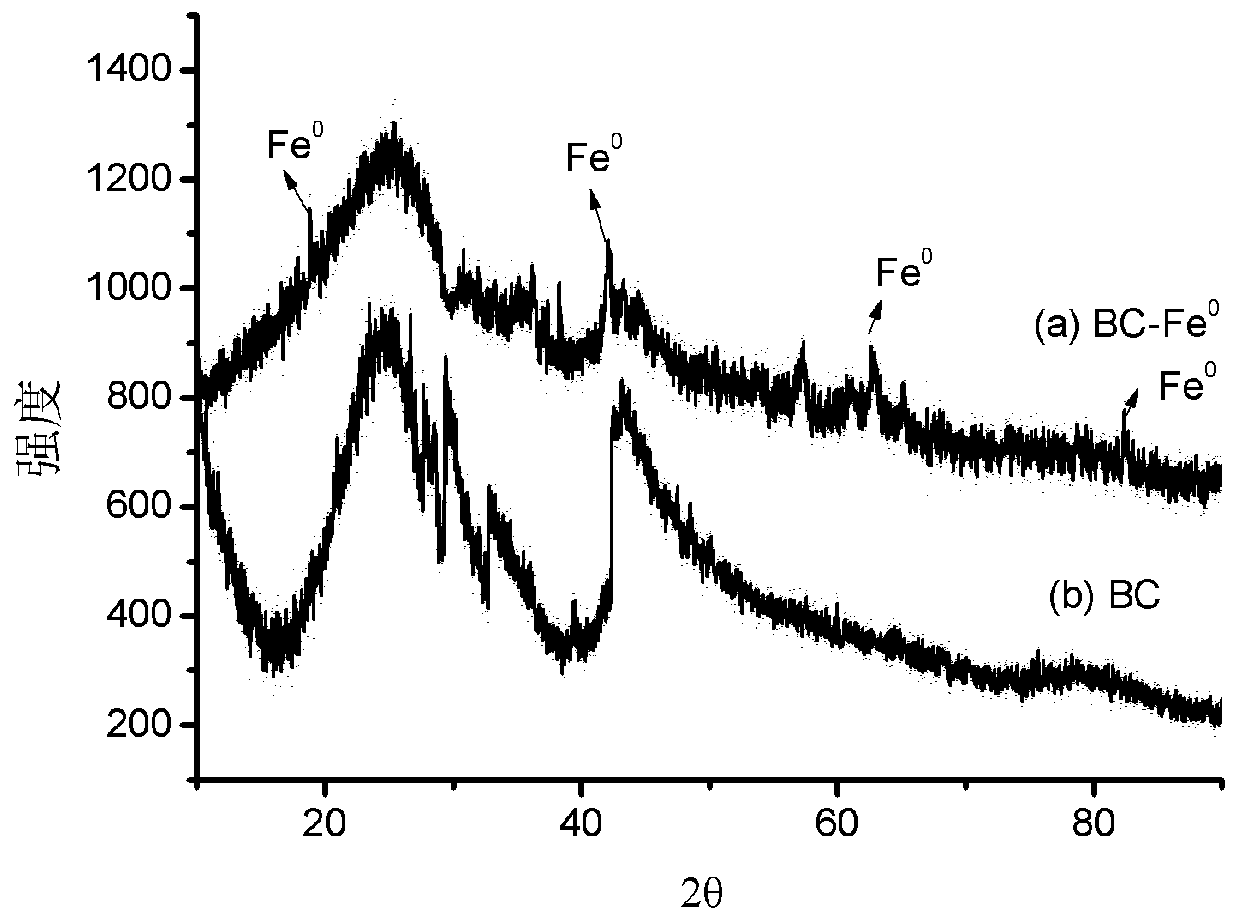

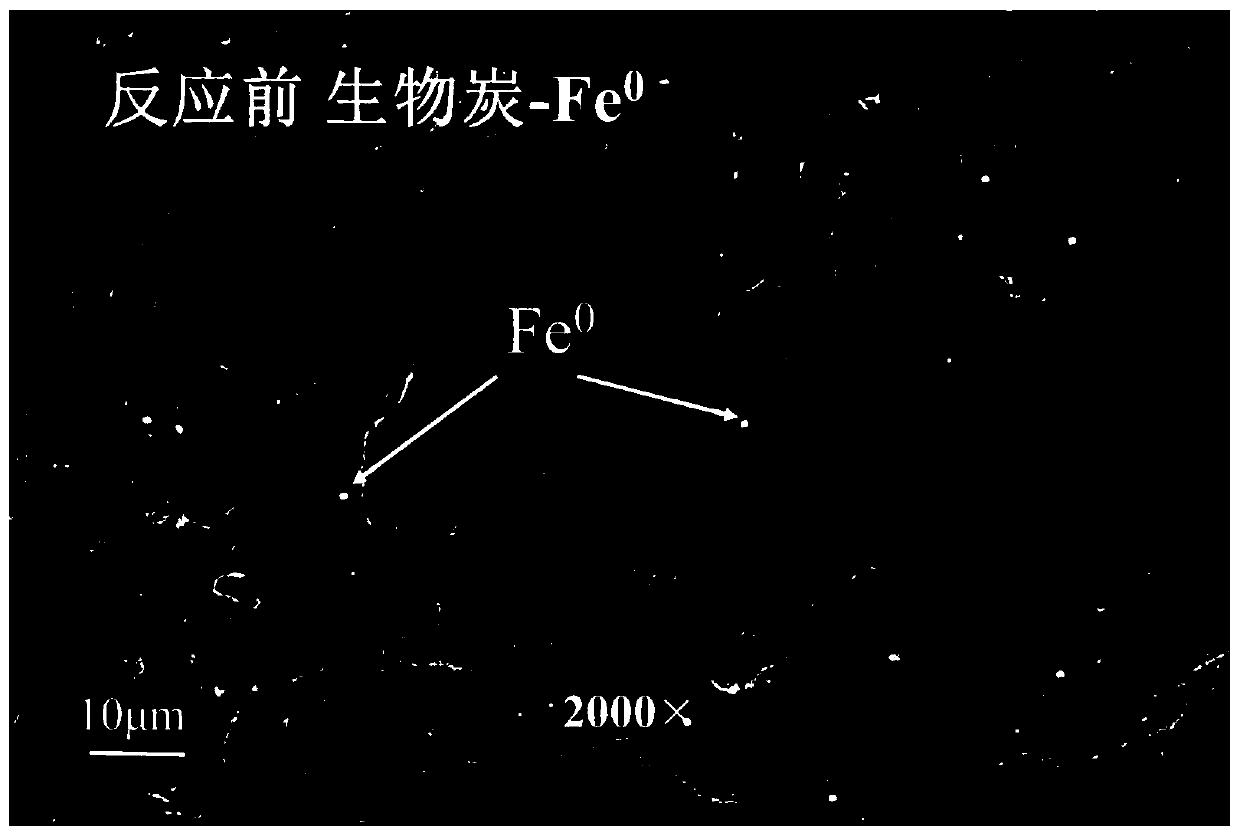

[0037] Add 0.6g of biomass to 100mL ferric chloride solution with a concentration of 0.5mol / L, stir at 60rpm for 8h to make it evenly mixed, then add ammonia water with a concentration of 10%, adjust the pH of the solution to 5-7, filter The biomass was washed several times with deionized water, dried at 80°C, and then roasted at 600°C for 8 hours under anaerobic conditions to obtain the biochar-based zero-valent iron restoration material BC-Fe 0 (FeCl 3 ).

[0038] Add 0.6g of biomass to 100mL ferric nitrate solution with a concentration of 0.5mol / L, stir at 60rpm for 8h to make it evenly mixed, then add ammonia water with a concentration of 10%, adjust the pH of the solution to 5-7, The biomass was filtered and washed several times with deionized water, dried at 80°C and then roasted at 600°C for 8 hours under anaerobic conditions to obtain the biochar-based zero-valent iron restoration material BC-Fe 0 (Fe(NO 3 ) 3 ).

[0039] Add 0.6g of biomass to 100mL ferric citrate ...

Embodiment 2

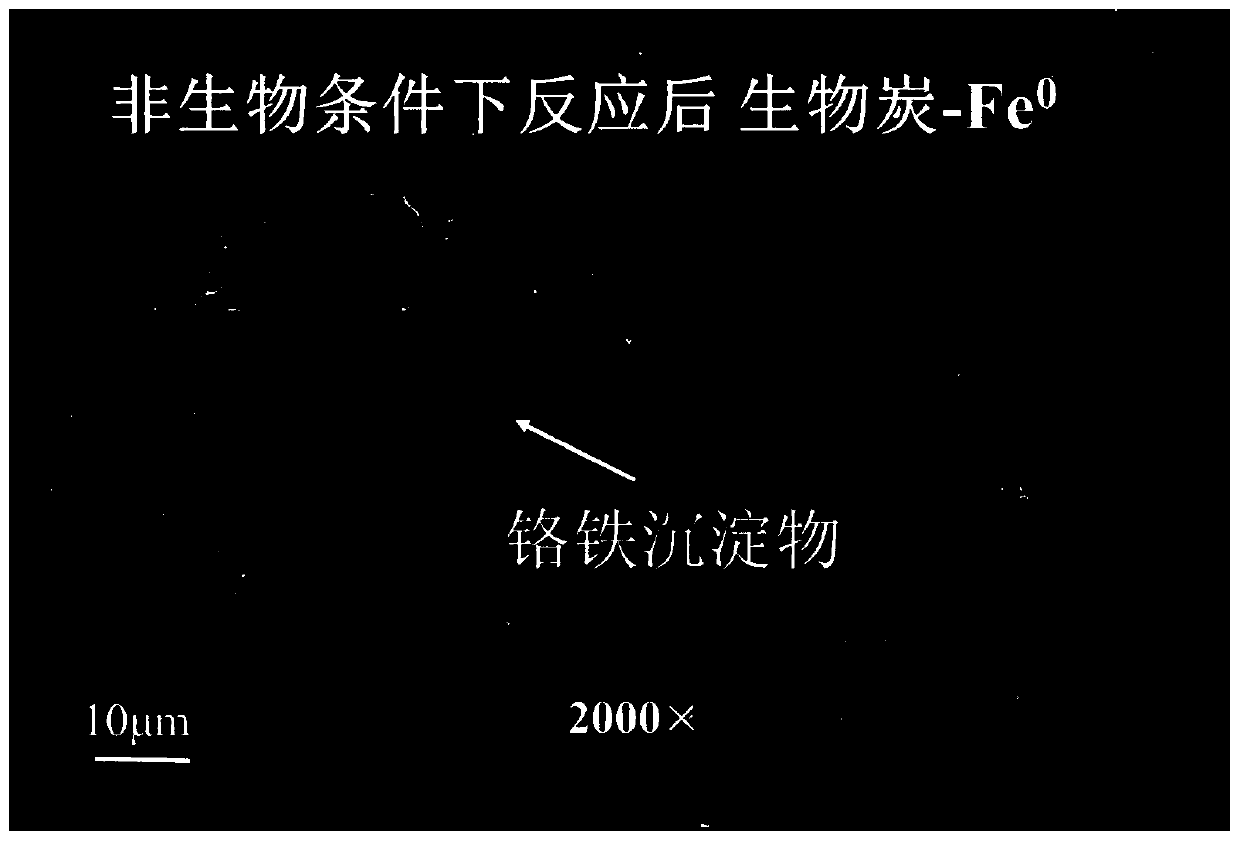

[0046] Biochar-based zero-valent iron (BC-Fe 0 (FeCl 3 )) and bacterial suspension preparation method are the same as in Example 1. Weigh 10g of chromium-contaminated soil with a concentration of 200mg / kg and transfer it to a 50mL centrifuge tube. The original soil pH value is 6.2, adjust the soil moisture content to 60% with water, and add zero-valent iron or biochar at a concentration of 0.25g / kg. Based on zero-valent iron and a bacterial suspension with a concentration of 80 mg / kg, mix them evenly, cover and seal them, and culture them statically at room temperature 20°C, 25°C and 30°C for 14 days. After the reaction, add quantitative deionized water and centrifuge at 4000rpm for 10 minutes to measure the chromium concentration in the supernatant; measure the change of chromium occurrence form in the remediation soil by multi-step continuous extraction method.

[0047] Four reaction systems were set up in the remediation process: 1. Blank system, including blank or chromi...

Embodiment 3

[0060] Biochar-based zero-valent iron (BC-Fe 0 (FeCl 3 )) and bacterial suspension preparation method are the same as in Example 1. Weigh 10g of chromium-contaminated soil with a concentration of 200mg / kg and transfer it to a 50mL centrifuge tube. kg of biochar-based zero-valent iron and bacterial suspension with a concentration of 80 mg / kg, mix well, cover and seal, and culture at room temperature 30°C for 14 days. After the reaction, add quantitative deionized water and centrifuge at 4000 rpm for 10 minutes to measure the chromium concentration in the supernatant. It can be seen from Table 6 that when the dosage of biochar-based zero-valent iron increases from 0.05 to 1g / kg, the removal ability of soil water-soluble hexavalent chromium after 14 days of reaction increases from 23mg Cr / g Fe 0 Rise to 53mgCr / g Fe 0 , the removal capacity of total chromium from 34mg Total Cr / g Fe 0 Rise to 79mg Total Cr / g Fe 0 , but when the amount of biochar-based zero-valent iron exceeds...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com