Method of synthesizing arbutin by using solid superacid as catalyst

A solid superacid and catalyst technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, organic chemistry, etc. It can solve the problems of a large amount of waste acid, expensive reagents, and inability to repeat applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

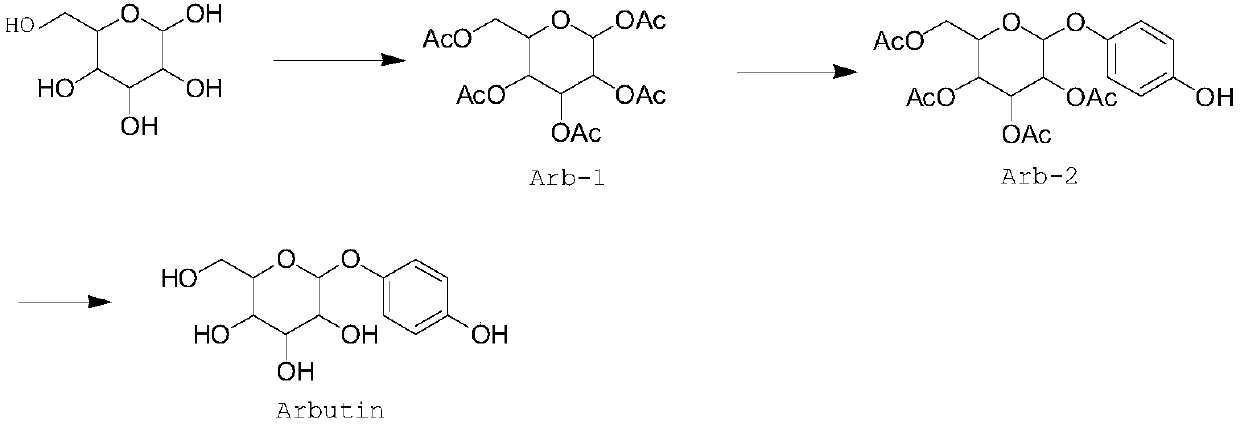

[0035] A kind of method adopting solid superacid as catalyst synthetic arbutin, it comprises the steps:

[0036]S1, preparation of solid superacid catalyst: Dissolve 20g of FeCl3 in 200g deionized water, add 100g of ammonia precipitation agent, and precipitate at room temperature for 12hrs to obtain Fe(OH)3 sol, which is filtered, washed with 20g deionized water, and washed with 100- After drying at 120°C, cool down to room temperature, impregnate with 100ml of 2.5mol / L sulfuric acid solution, filter and dry, bake at 300-500°C for 8-20hrs after drying, and then cool down to room temperature in a dry nitrogen environment to obtain a brown catalyst About 22g;

[0037] S2, preparation of intermediate Arb-1: Add 120g of acetic anhydride and 12g of sodium acetate into the reaction kettle in turn, stir and heat up to 60-80°C, add 40g of glucose in 3 batches, control the reaction temperature ≤ 100°C, after the addition is complete Control the temperature at 120-125°C for reaction an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com