Vinyl sulfone-functionalized polysulfone membrane and preparation method and application thereof

A vinyl sulfone and functionalization technology, applied in the direction of surface/boundary effects, instruments, analytical materials, etc., can solve problems such as the preparation method of polysulfone membranes without vinyl sulfone groups, and achieve a wide range of substrates and great application prospects , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: Sample preparation and characterization

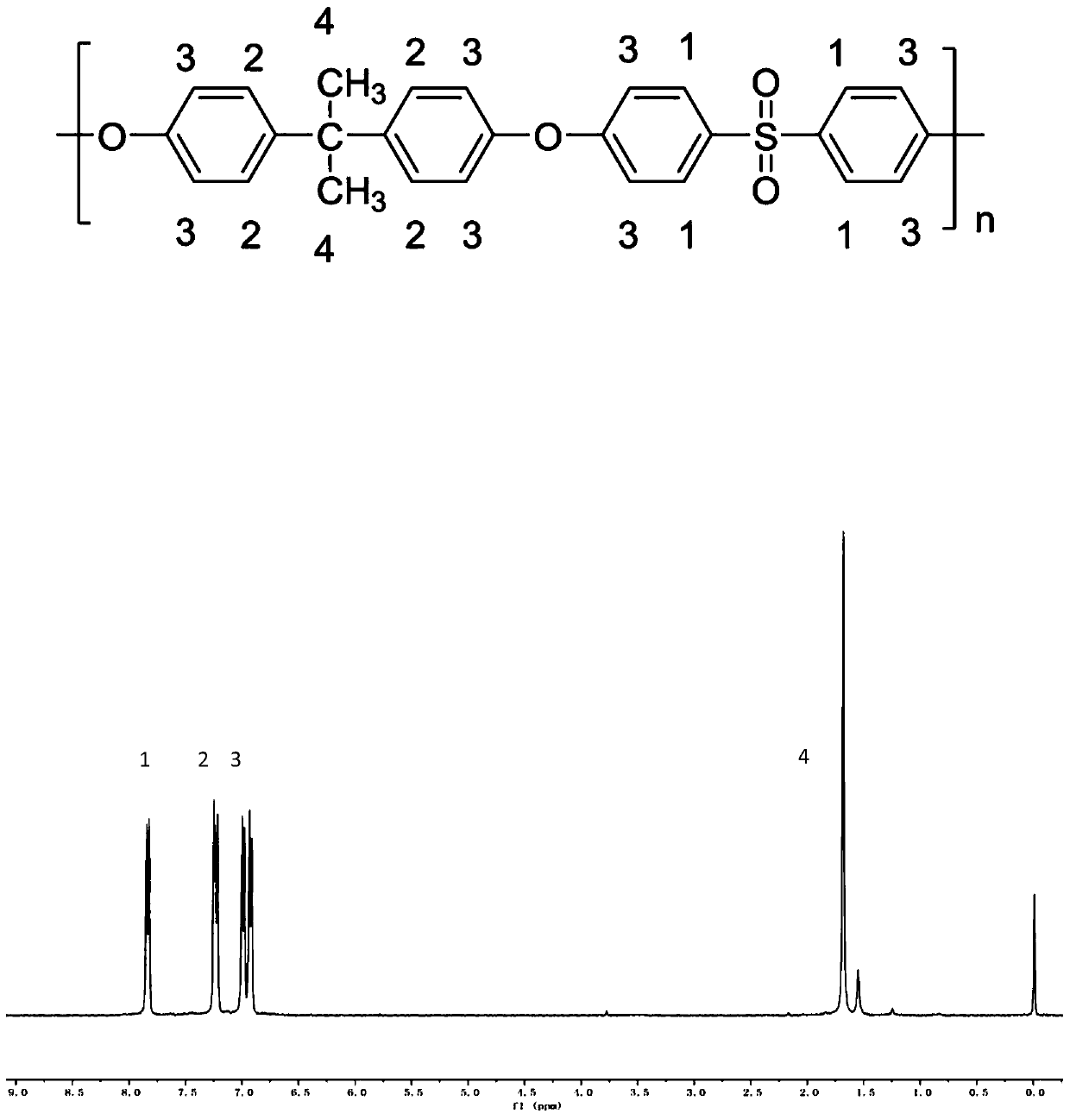

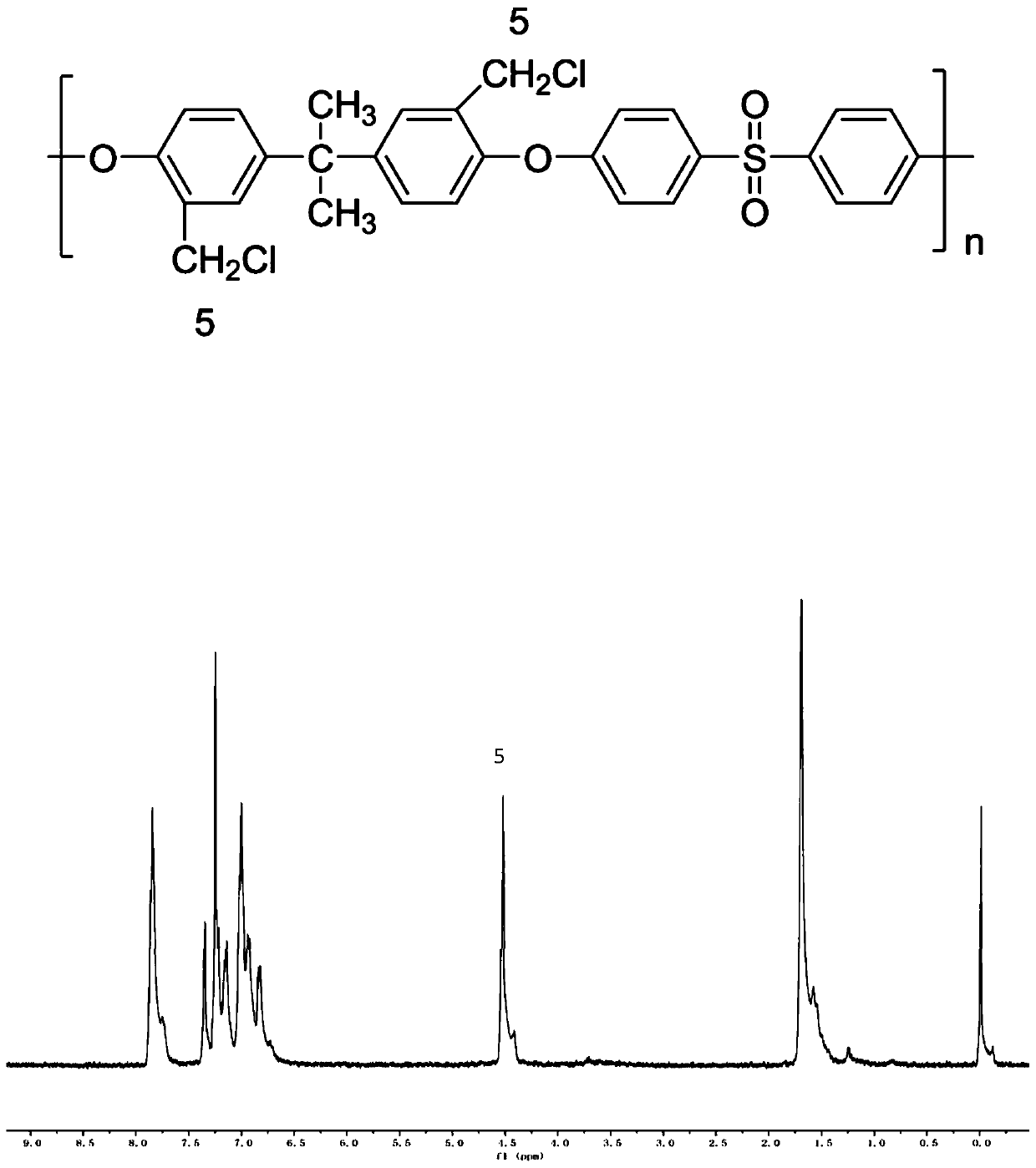

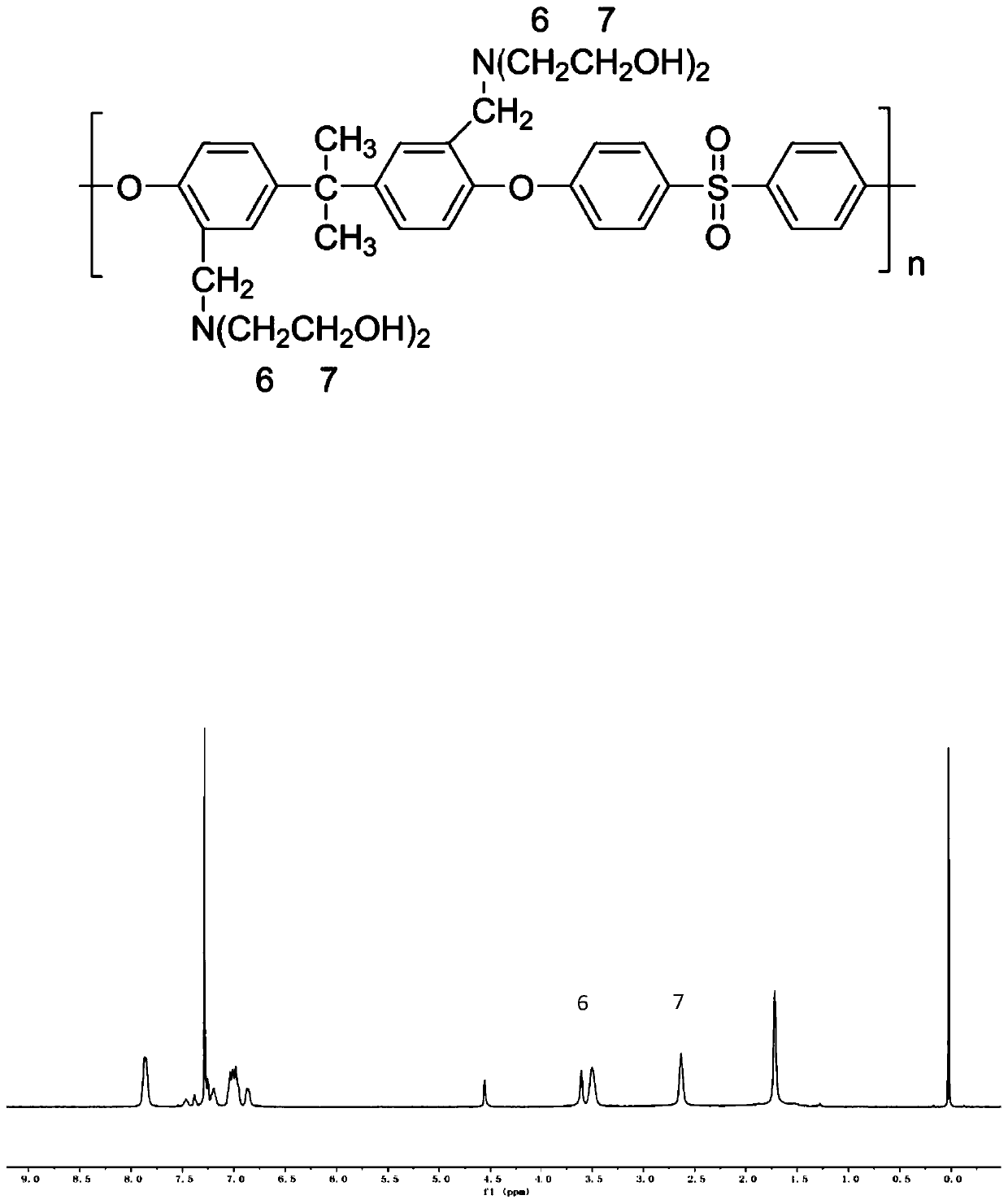

[0045] Take 500mg polysulfone particles (PSF) and dissolve in 20mL chloroform, its 1 HNMR spectrum as figure 1 As shown, trimethylchlorosilane (1.44 mL), paraformaldehyde (341 mg), and tin tetrachloride (20 μL) were added in sequence. Under the protective gas argon atmosphere, reflux at 50° C. for 48 h. After the reaction, recrystallize with methanol, wash and dry to obtain chloromethylated polysulfone material (CMPSF), which 1 HNMR spectrum as figure 2shown. Take 160 mg of CMPSF sample and dissolve it in 10 mL of dichloromethane, add 500 μL of diethanolamine, use chromatographic acetonitrile to help dissolve it until it is completely dissolved, and react at 25°C for 12 hours. After the reaction, recrystallize with methanol, wash and dry to obtain diethanolamine functionalized polysulfone material (DEAPSF), which 1 HNMR spectrum as image 3 shown. Take 100mg DEAPSF sample, dissolve it in 3mL dichloromethane...

Embodiment 2

[0047] Example 2: immobilization of small biomolecules

[0048] In order to verify that the material can react with small molecules, the material was made into a film, and the static water contact angle was measured. Take 100 mg of the DEAPSF sample in Example 1, dissolve it in 3 mL of dichloromethane, and form a film by phase inversion method. The DEAPSF membrane was submerged in divinyl sulfone (500 mM) solution, acetonitrile was used as solvent, and reacted at 25°C for 12 hours under the catalysis of triphenylphosphine (10 mM). After taking it out, rinse it with acetonitrile and ethanol in sequence, and blow it dry with nitrogen gas to obtain a vinyl sulfone functionalized polysulfone material (DVSPSF). Drop 2 μL of ultrapure water to test the static water contact angle. The DVSPSF membrane obtained in the previous step was placed in a cysteine (10 mM) solution (pH 6.5), reacted at 25°C for 4 hours, and dried with nitrogen to obtain a cysteine-modified polysulfone membra...

Embodiment 3

[0050] Embodiment 3: Anti-protein adsorption experiment

[0051] (1) Place the DVSPSF membrane prepared in Example 1 in NH 2 -PEG 2000 Solution (0.3g / mL, pH=8.0PB buffer), reacted at 60°C for 12 hours, and dried with nitrogen to obtain PEG 2000 - PSF membrane.

[0052] (2) PSF, PEG 2000 - The membrane of PSF was cut into circular membrane pieces with a diameter of 0.5 cm, 6 pieces of each kind were cut out.

[0053] (3) Place the trimmed samples in a 96-well plate, add 100 μL of HRP-labeled goat anti-human IgG (Beijing Suolaibao Technology Co., Ltd.) to three of each sample, and add 100 μL of HRP-labeled anti-human IgG to the other three BSA (0.1 mg / mL) (Beijing Suo Lai Bao Technology Co., Ltd.), incubated at 37 ° C for 1 h. After the reaction, the two proteins were sucked out, and then the membrane adsorbed by the protein was taken out, washed three times with ultrapure water buffer, and dried with nitrogen.

[0054] (4) Put the membrane back into a clean 96-well plate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com