Hollow microspheres for high temperature resistant thermal insulation coating and preparation method and application thereof

A technology of hollow microbeads, thermal insulation, applied in chemical instruments and methods, reflective/signal coatings, fibrous fillers, etc., can solve the problems that the titanium dioxide coating layer is easy to fall off and cannot achieve synergistic effect, and achieve enhanced combination Strength, enhanced heat insulation rate, and the effect of avoiding falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

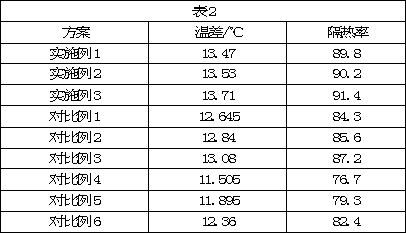

Embodiment 1

[0021] (1) Cleaning: Wash the hollow microspheres with a particle size of 50um and a wall thickness of 10um with acetone and deionization for 3 times in sequence until the surface oil is removed;

[0022] (2) Acid leaching: Add the cleaned hollow microspheres to a dilute solution with a mass fraction of 1% hydrofluoric acid and soak for 0.5h to form micro-etching on the surface of the hollow microspheres;

[0023] (3) Detonation: Add acid-leached hollow microspheres and sodium azide with a mass ratio of 10:2 into deionized water, stir and mix, add liquid nitrogen, and freeze-dry to make sodium azide Evenly adhere to the brown wrinkles produced by acid leaching on the surface of the hollow microspheres, and then place them in a closed reactor to trigger an explosive reaction, then wash with deionized water and dry;

[0024] (4) Coating: first mix and stir butyl titanate, absolute ethanol, acetylacetone and distilled water evenly, the molar ratio of butyl titanate, absolute etha...

Embodiment 2

[0026] (1) Cleaning: Wash the hollow microspheres with a particle size of 200um and a wall thickness of 30um with acetone and deionization for 3 times in sequence until the surface oil is removed;

[0027] (2) Acid leaching: Add the cleaned hollow microspheres to a dilute solution with a mass fraction of 3% hydrofluoric acid and soak for 1 hour to form micro-etching on the surface of the hollow microspheres;

[0028] (3) Detonation: Add acid-leached hollow microspheres and sodium azide with a mass ratio of 5:2 into deionized water, stir and mix, add liquid nitrogen, and freeze-dry to make sodium azide Evenly adhere to the brown wrinkles produced by acid leaching on the surface of the hollow microspheres, and then place them in a closed reactor to trigger an explosive reaction, then wash with deionized water and dry;

[0029] (4) Coating: first mix and stir butyl titanate, absolute ethanol, acetylacetone and distilled water evenly, the molar ratio of butyl titanate, absolute et...

Embodiment 3

[0031](1) Cleaning: Wash the hollow microspheres with a particle size of 500um and a wall thickness of 50um with acetone and deionization for 3 times in sequence until the surface oil is removed;

[0032] (2) Acid leaching: Add the cleaned hollow microspheres to a dilute solution with a mass fraction of 5% hydrofluoric acid and soak for 2 hours to form micro-etching on the surface of the hollow microspheres;

[0033] (3) Detonation: Add acid-leached hollow microspheres and sodium azide with a mass ratio of 5:3 into deionized water, stir and mix, add liquid nitrogen, and freeze-dry to make sodium azide Evenly adhere to the brown wrinkles produced by acid leaching on the surface of the hollow microspheres, and then place them in a closed reactor to trigger an explosive reaction, then wash with deionized water and dry;

[0034] (4) Coating: first mix and stir butyl titanate, absolute ethanol, acetylacetone and distilled water evenly, the molar ratio of butyl titanate, absolute et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com