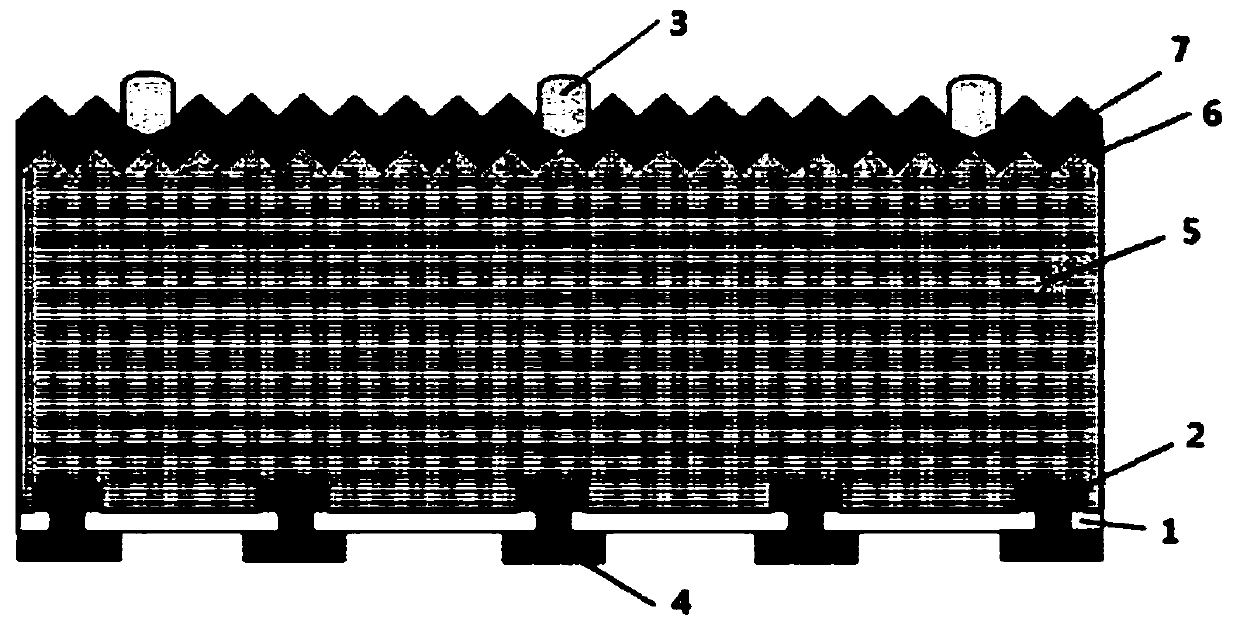

Double-sided power generation solar cell and preparation method thereof

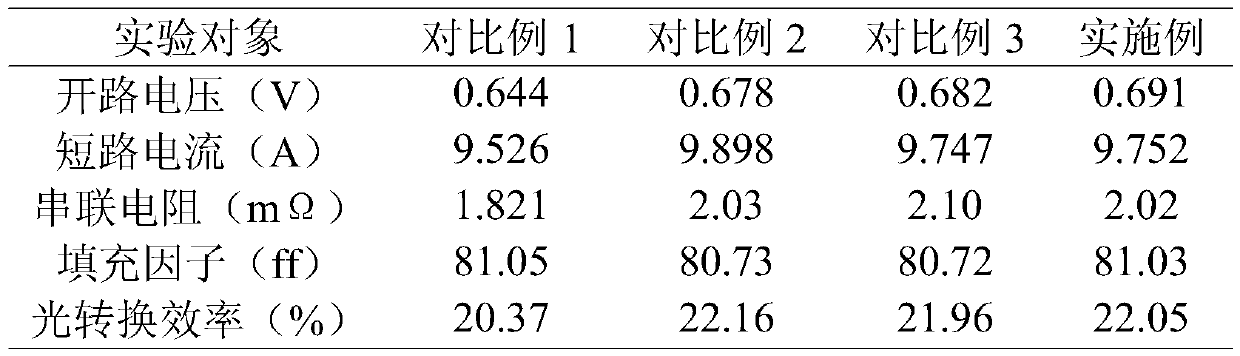

A solar cell, double-sided technology, used in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of incomplete etching of aluminum paste, large damage to solar cells, large amount of aluminum paste, etc., and achieve passivation on the back of etching. The effect of uniform film, improving photoelectric conversion efficiency and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The preparation method of the partial aluminum back field solar cell is as follows:

[0056] S1: Select 156×156mm P-type silicon, form a textured surface on the front side of the silicon wafer, use wet or dry etching technology to form a textured surface on the surface of the P-type silicon wafer, and control the reflectivity at 20%.

[0057] S2: Phosphorus is diffused on the front side of the silicon wafer treated in S1 to form an N-type emitter. The N-type emitter can be formed by thermal diffusion or ion implantation, wherein the diffusion of the silicon wafer is preferably made of phosphorus oxychloride , it is necessary to control the sheet resistance at 90ohm / sq during diffusion.

[0058] S3: On the basis of S2, the device removes the phosphosilicate glass formed during the diffusion process, and uses HF solution to remove the phosphosilicate glass layer formed during the diffusion process on the front of the N-type emitter and the back of the P-type silicon wafer...

Embodiment 2

[0065] S1: Select 156×156mm P-type silicon, form a textured surface on the front side of the silicon wafer, use wet or dry etching technology to form a textured surface on the surface of the P-type silicon wafer, and control the reflectivity at 10%.

[0066] S2: Phosphorus is diffused on the front side of the silicon wafer treated in S1 to form an N-type emitter. The N-type emitter can be formed by thermal diffusion or ion implantation, wherein the diffusion of the silicon wafer is preferably made of phosphorus oxychloride , it is necessary to control the sheet resistance at 75ohm / sq during diffusion.

[0067] S3: On the basis of S2, the device removes the phosphosilicate glass formed during the diffusion process, and uses HF solution to remove the phosphosilicate glass layer formed during the diffusion process on the front of the N-type emitter and the back of the P-type silicon wafer.

[0068] S4: Use PVECD equipment to first deposit 8nm aluminum oxide or silicon dioxide on ...

Embodiment 3

[0074] S1: Select 156×156mm P-type silicon, form a textured surface on the front side of the silicon wafer, use wet or dry etching technology to form a textured surface on the surface of the P-type silicon wafer, and control the reflectivity at 30%.

[0075] S2: Phosphorus is diffused on the front side of the silicon wafer treated in S1 to form an N-type emitter. The N-type emitter can be formed by thermal diffusion or ion implantation, wherein the diffusion of the silicon wafer is preferably made of phosphorus oxychloride , it is necessary to control the sheet resistance at 75ohm / sq during diffusion.

[0076] S3: On the basis of S2, the device removes the phosphosilicate glass formed during the diffusion process, and uses HF solution to remove the phosphosilicate glass layer formed during the diffusion process on the front of the N-type emitter and the back of the P-type silicon wafer.

[0077] S4: Use PVECD equipment to first deposit 8nm aluminum oxide or silicon dioxide on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com