Silicon-boron-modified thermosetting phenolic resin hollow microsphere, and preparation method and application thereof

A phenolic resin and thermosetting technology, which is applied in the field of thermosetting phenolic resin hollow microspheres and its preparation, can solve the problems of mechanical property damage, decreased thermal insulation performance, and phenolic resin hollow microspheres cannot meet the ablation resistance and other problems, and achieves mechanical properties. The effect of excellent, excellent ablation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides a method for preparing silicon-boron modified thermosetting phenolic resin hollow microspheres described in the above technical solution, comprising the following steps:

[0045] After mixing water, core material and surfactant, adding silicon boron-modified thermosetting phenolic resin for preforming to obtain a preforming mixture;

[0046] After mixing the preformed mixed solution with an accelerator, precure to obtain precured microspheres;

[0047] The pre-cured microspheres are subjected to deep curing molding to obtain silicon-boron-modified thermosetting phenolic resin hollow microspheres.

[0048]In the invention, after mixing water, core material and surface active agent, silicon boron modified thermosetting phenolic resin is added for preforming to obtain a preforming mixed liquid. In the present invention, the water, core material and surfactant are mixed to form an "oil-in-water" emulsified dispersion system, wherein the ...

Embodiment 1

[0063] (1) Preparation of silicon boron modified thermosetting phenolic resin:

[0064] According to the ratio of phenol:boric acid molar ratio of 5:1, add it into a three-necked flask equipped with a thermometer, condensing device, and stirring device, control the temperature at 90°C, react for 6h, then cool down to 70°C, and add at 70°C with a mass concentration of 20% sodium hydroxide aqueous solution and paraformaldehyde, wherein the mass of sodium hydroxide aqueous solution accounts for 4% of phenol, and the molar ratio of paraformaldehyde and phenol is 1.3:1. After continuing to react for 6 hours, press phenyltriethoxysilane : Add phenylethoxysilane with a phenol molar ratio of 1:7, continue the reaction for 1 hour, and vacuum dehydrate to obtain SiBPR-1;

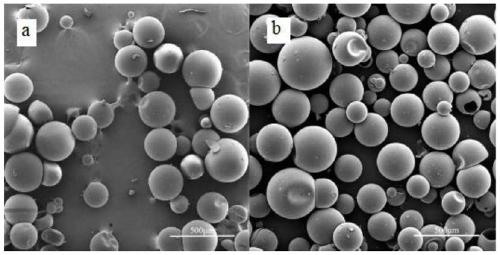

[0065] (2) Preparation of thermosetting phenolic resin hollow microspheres modified by silicon boron

[0066] 1) Add 40g of deionized water, 10g of tetraethyl orthosilicate and 22g of polyacrylic acid into a three-ne...

Embodiment 2

[0077] (1) Preparation of silicon boron modified thermosetting phenolic resin:

[0078]According to the ratio of phenol:boric acid molar ratio of 3:1, add it into a three-necked flask equipped with a thermometer, a condensing device, and a stirring device, control the temperature at 90°C, react for 6h, then cool down to 70°C, and add a concentration of 20 at 70°C % sodium hydroxide aqueous solution and paraformaldehyde, wherein the quality of sodium hydroxide aqueous solution is 4% of phenol, the molar ratio of paraformaldehyde and phenol is 1.3:1, after continuing to react for 6h, press phenyltriethoxysilane : Add phenyltriethoxysilane at a phenol molar ratio of 1:9, react for 1 hour, and vacuum dehydrate to obtain SiBPR-2.

[0079] (2) Preparation of thermosetting phenolic resin hollow microspheres modified by silicon boron

[0080] 1) Add 40g of deionized water, 12g of methyl silicone oil and 25g of polyvinyl alcohol into a three-necked flask, control the stirring speed at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average wall thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap