Macro and controllable preparation method of large-diameter and narrow-diameter distribution single-walled carbon nano-tubes

A technology of single-walled carbon nanotubes and diameter distribution, applied in the direction of carbon nanotubes, nanocarbons, chemical instruments and methods, etc., can solve the problems of poor product uniformity, low proportion of single-walled carbon nanotubes, etc., and achieve low impurity content , Low amount of catalyst residue and complete structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this example, firstly, a mixed solution of toluene, ferrocene, and thiophene with a mass ratio of 100:9.5:2.5 was prepared, and ultrasonically treated for 10 minutes for later use. Under the protection of a small flow rate of 200 sccm hydrogen, raise the temperature of the chemical vapor deposition horizontal tube furnace to 1200 ° C, then adjust the hydrogen flow rate to 4300 sccm, and feed 10.5 sccm methane and 6.2 sccm ethylene at a rate of 0.53 ml / h A mixed solution prepared by toluene, ferrocene and thiophene was injected at a constant speed to grow carbon nanotubes for 1 hour. The sample was collected and weighed, the sample weighed 0.3g, and the carbon source conversion rate was calculated to be 25%.

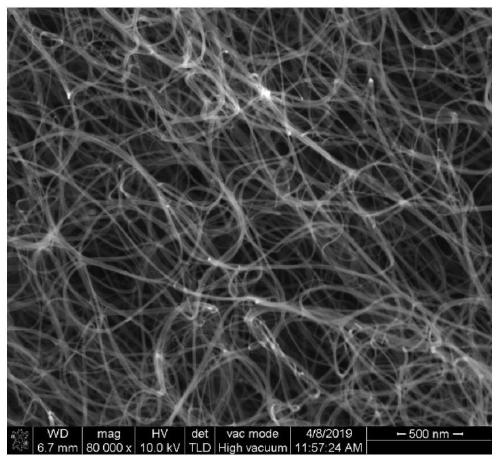

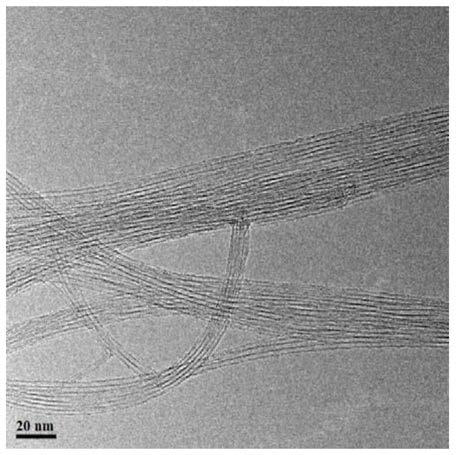

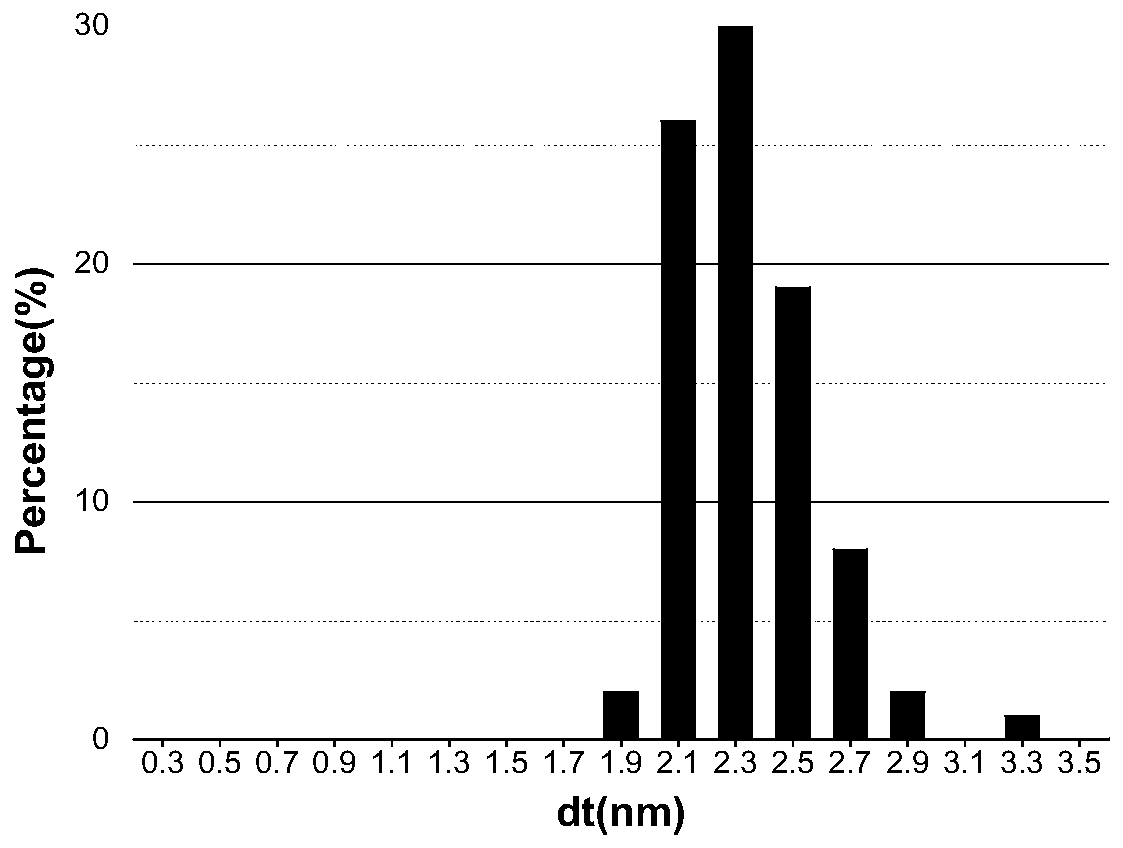

[0035] Such as figure 1 As shown, the product sample is characterized by scanning electron microscope and transmission electron microscope. It can be seen from the typical scanning electron microscope photo of the prepared single-walled carbon nanotube that the...

Embodiment 2

[0037] In this example, firstly, a mixed solution of toluene, ferrocene and thiophene with a mass ratio of 100:10.3:2.6 was prepared, and ultrasonically treated for 10 minutes for later use. Under the protection of a small flow rate of 200sccm hydrogen, the chemical vapor deposition horizontal tube furnace was heated to 1200°C, then the hydrogen flow rate was adjusted to 4000sccm, and 17sccm methane and 6.9sccm ethylene were introduced at a constant rate of 0.54ml / h A mixed solution prepared by injecting toluene, ferrocene, and thiophene was injected to grow carbon nanotubes for 2 hours. The sample was collected and weighed, the sample weighed 0.21 g, and the carbon source conversion rate was calculated to be 17%.

[0038] The structure of the prepared carbon nanotubes was characterized by scanning electron microscope, transmission electron microscope and differential thermal analysis respectively. The large-diameter single-walled carbon nanotubes produced by this process par...

Embodiment 3

[0040] In this example, a mixed solution of toluene, ferrocene, and thiophene with a mass ratio of 100:7.8:2.0 was first prepared, and the solution was ultrasonically treated for 10 minutes for later use. Under the protection of a small flow rate of 200 sccm hydrogen, raise the temperature of the chemical vapor deposition horizontal tube furnace to 1200 °C, then adjust the hydrogen flow rate to 3800 sccm, and feed 13.5 sccm methane and 6.2 sccm ethylene at a rate of 0.53 ml / h A mixed solution prepared by toluene, ferrocene and thiophene was injected at a constant speed to grow carbon nanotubes for 1 hour. The sample was collected and weighed, the sample weighed 0.24g, and the carbon source conversion rate was calculated to be 20%.

[0041] The structure of the prepared carbon nanotubes was characterized by scanning electron microscope, transmission electron microscope and differential thermal analysis respectively. The large-diameter single-walled carbon nanotubes produced by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com