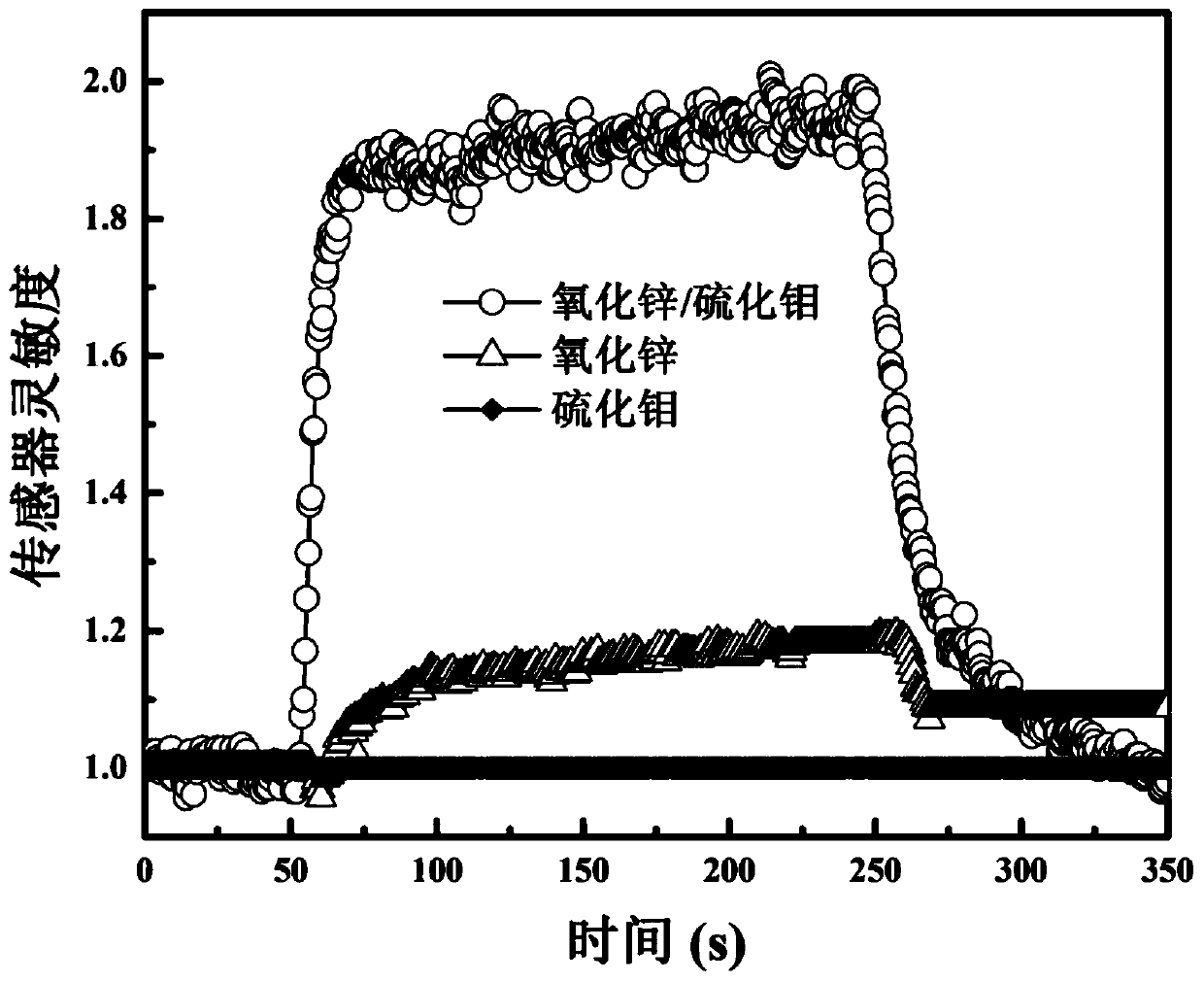

Zinc oxide/molybdenum sulfide thin film sensitive to extremely low concentration acetone

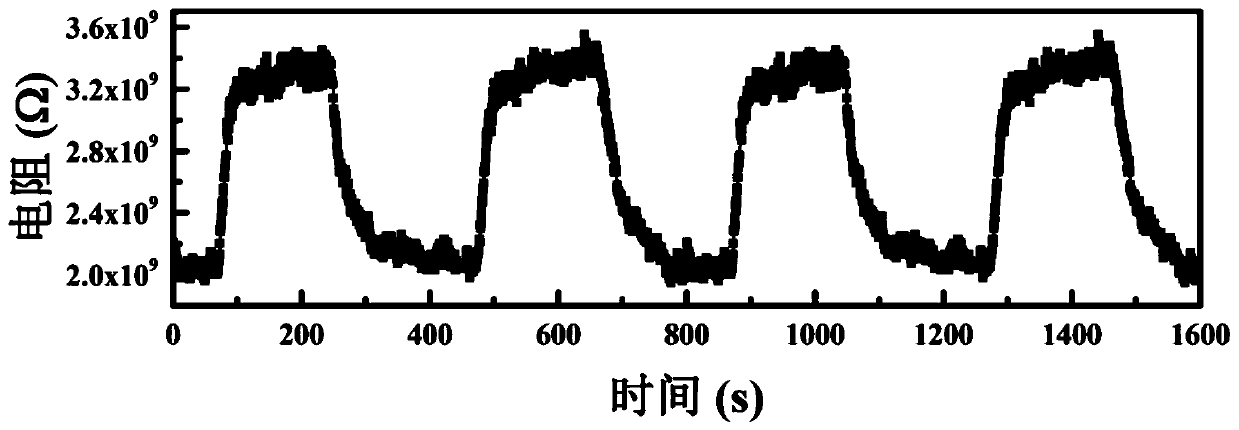

A low-concentration zinc oxide technology, applied in the field of gas sensors, achieves the effects of low raw material cost, good repeatability, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1, 0.5578 grams of zinc nitrate hexahydrate was dissolved in 15 milliliters of methanol, stirred for 15 minutes, 0.6158 grams of dimethylimidazole was mixed with 15 milliliters of methanol, stirred for 15 minutes, and dispersed uniformly by ultrasonic, then the zinc nitrate hexahydrate was mixed The solution was added dropwise into the dimethylimidazole solution, stirred at room temperature for 10 hours, centrifuged, washed with methanol several times, and then the centrifuged sample was vacuum-dried at 60° C. to obtain ZIF-8 powder. The above ZIF-8 powder was heat-treated in a tube furnace at 500°C for 2 hours in a nitrogen atmosphere, then at 350°C in an air atmosphere for 2 hours at a heating rate of 1°C / min, and finally zinc oxide powder was obtained ; Dissolve 0.06 gram of zinc oxide powder in 40 milliliters of deionized water, ultrasonic 60 minutes, obtain zinc oxide solution; Add 0.123 gram of ammonium molybdate tetrahydrate and 0.228 gram of thiourea to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com