Online monitoring early-warning device and method for anaerobic fermentation process

An anaerobic fermentation and automatic control system technology, which is applied in the field of online early warning system devices, can solve problems such as inaccurate titration results, and achieve the effects of saving manpower and material resources, accurate monitoring results, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

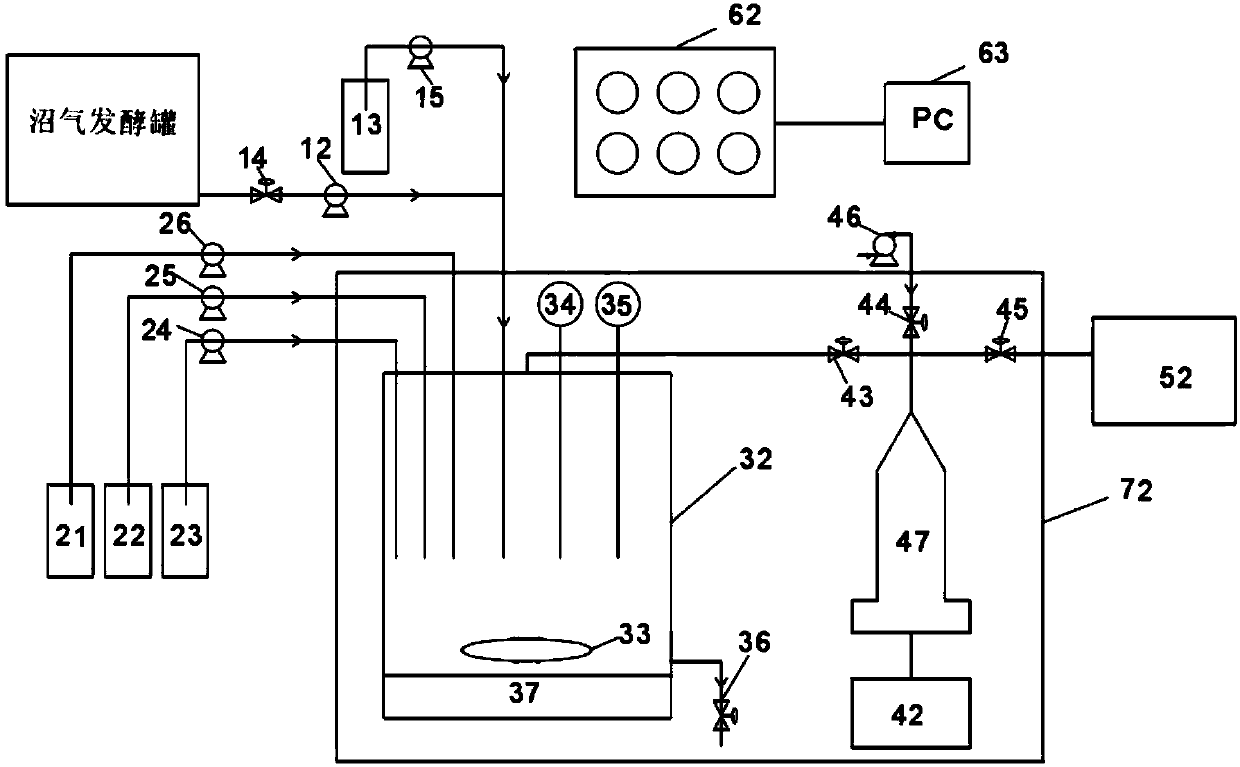

[0082] Monitoring method of anaerobic fermentation online monitoring and early warning device

[0083] Step 1: Sample collection. According to the system setting, the first peristaltic pump pumps 20-40mL sample to the reaction tank of the sample processing system, and after obtaining the liquid to be tested, the automatic control system sends instructions to the drug dosing system

[0084] Step 2: Drug addition. The first acid metering pump of the chemical dosing system starts, and pumps 2-4mL of phosphoric acid, formic acid, oxalic acid, hydrochloric acid or citric acid solution into the reaction tank of the sample processing system to meet the pH value below 3.0; then the chemical dosing system Start the diacid metering pump, pump 1-2mL sodium bisulfate, sodium chloride, calcium chloride, sodium dihydrogen phosphate or ammonium sulfate solution into the reaction tank of the sample processing system to reduce the solubility of volatile fatty acids in the sample solution;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com