Alpha-NixFey(OH)2 electrocatalyst and application of alpha-NixFey(OH)2 electrocatalyst to working electrode

An electrocatalyst, a certain amount of technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, electrode, etc., can solve the cumbersome preparation method, unfavorable research and application of nickel-based hydroxide, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] a-Ni x Fe y (OH) 2 The preparation method of electrocatalyst comprises the following steps:

[0026] First prepare solution A, add a certain amount of nickel nitrate hexahydrate, iron nitrate nonahydrate and cetyltrimethylammonium bromide into ultrapure water or deionized water; then prepare solution B, add a certain amount of NaBH 4 Add to ultrapure water or deionized water; stir solution A continuously until the solute is completely dissolved, then add solution B dropwise to solution A, after the reaction, centrifuge the product, wash it with water and absolute ethanol several times, and then vacuum dry , to produce α-Ni x Fe y (OH) 2 .

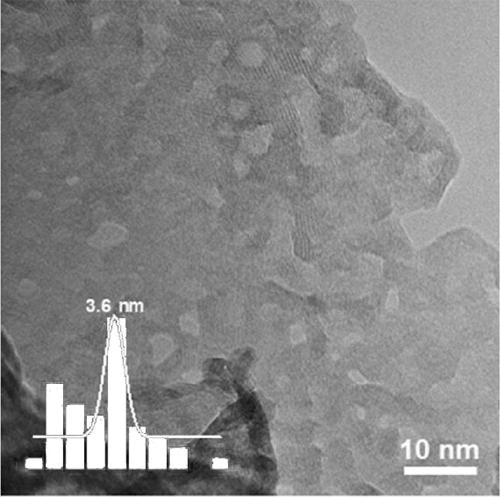

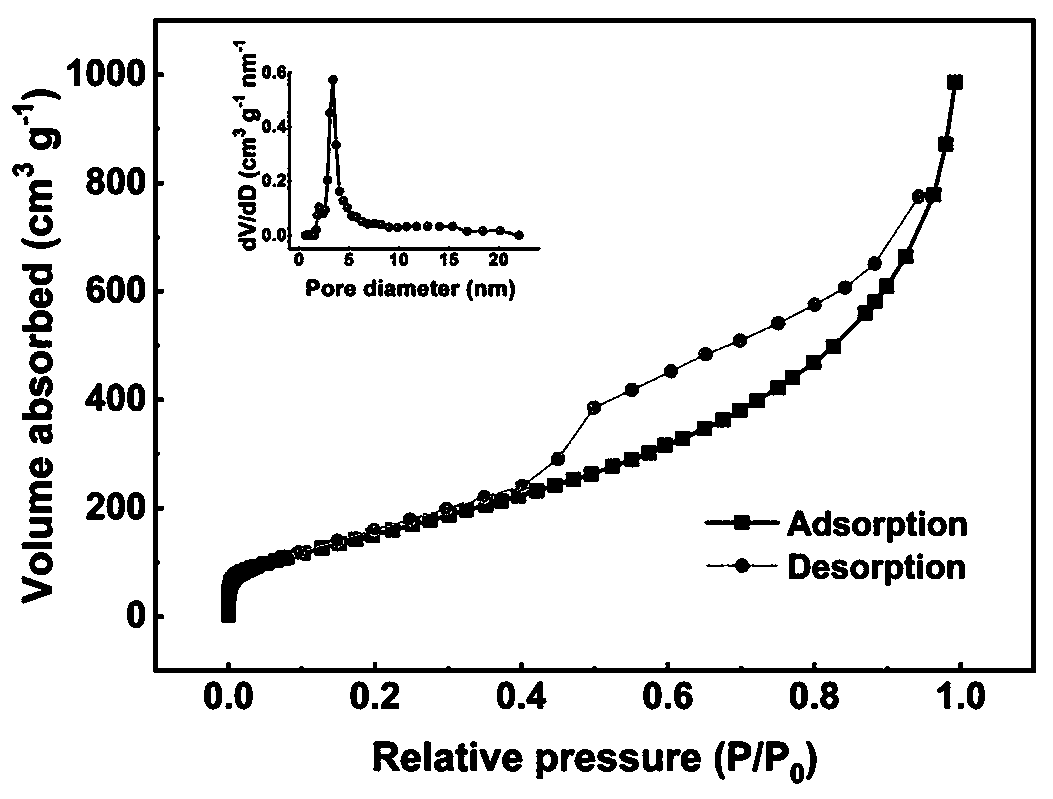

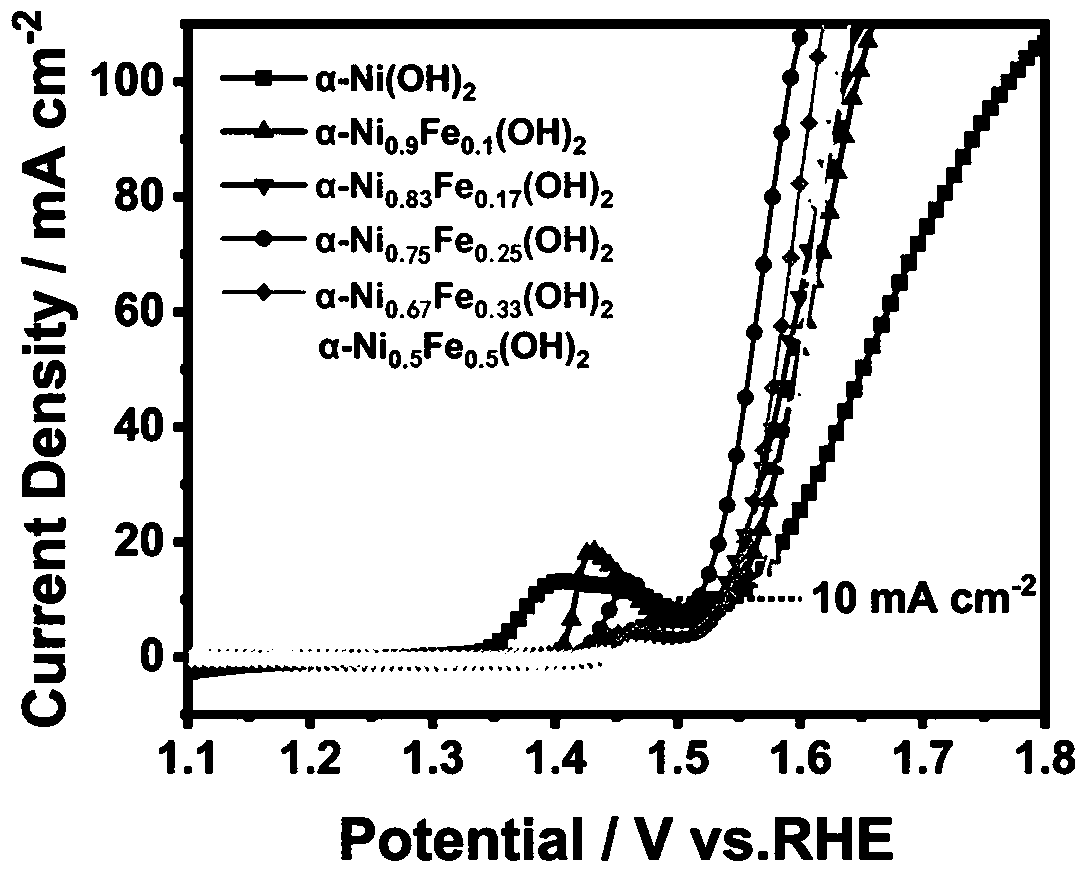

[0027] α-Ni synthesized in the present invention x Fe y (OH) 2 With nanometer-sized pores and uniform pores, this structure makes the α-Ni x Fe y (OH) 2 When used as a catalytic electrode material, it not only has a large specific surface area, but also has a good mass transfer effect and a large number of active sites, w...

Embodiment

[0033] One using NaBH 4 Rapid preparation of iron-doped α-Ni as "foaming agent" and coprecipitant x Fe y (OH) 2 The method and its OER performance comprise the following steps:

[0034] (1), α-Ni x Fe y (OH) 2 preparation of

[0035] First prepare solution A, a certain amount of nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O), ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) and 0.5 g of cetyltrimethylammonium bromide (CTAB) were added to 25 mL of ultrapure water or deionized water, where Fe(NO 3 ) 3 9H 2 O and Ni(NO 3 ) 2 ·6H 2 The molar amount of O is 2 mmol, and y / x is 0 / 1, 1 / 9, 1 / 5, 1 / 3, 1 / 2, 1 / 1. Then prepare solution B, 0.1 g NaBH 4 Add to 25 mL ultrapure or deionized water. Solution A was continuously stirred for a certain period of time to completely dissolve the solute, then solution B was added dropwise to solution A, and after 5 min of reaction, the product was centrifuged, washed with water and absolute ethanol several times, and then vacuum-dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com