Method for densifying FOX-7 explosives induced by lattice intercalation

A FOX-7, densification technology, used in explosives, explosives processing equipment, nitrified explosives components, etc., can solve the problems of not mentioning the relevant data of density enhancement, complex two-dimensional material process flow, high cost, and achieve a higher cost of raw materials. Low, improved detonation performance, high crystal density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 0.36g of triaminoguanidine nitrate and 2.25g of FOX-7, add 45mL of dimethyl sulfoxide to the reactant (at this time the solute concentration is 58mg / mL), heat to 105°C to mix the reactant evenly The glyoxal of 0.41g was added to the above-mentioned hot solution, and after stirring and reacting for 60 minutes at a rotating speed of 500rpm, a mixed solution was obtained; 45mL deionized water was added to the mixed solution to separate out the product; finally, the product was filtered, washed with deionized water, After vacuum drying, a high-density FOX-7-based composite material can be obtained with a yield of 98.7%.

example 1

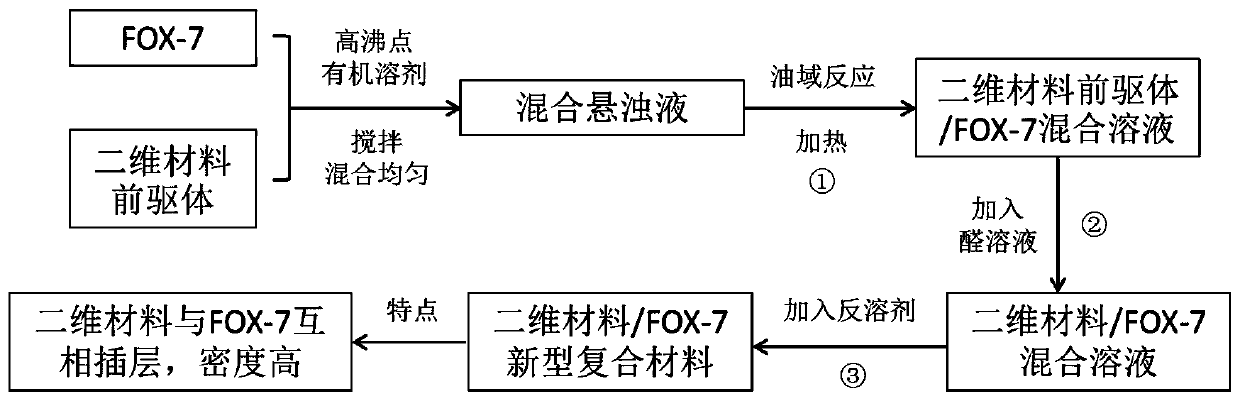

[0029] The flow chart of the high-density FOX-7 base composite material prepared by example 1 is shown as figure 1 shown.

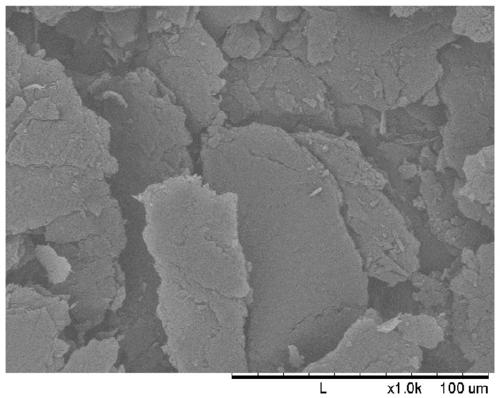

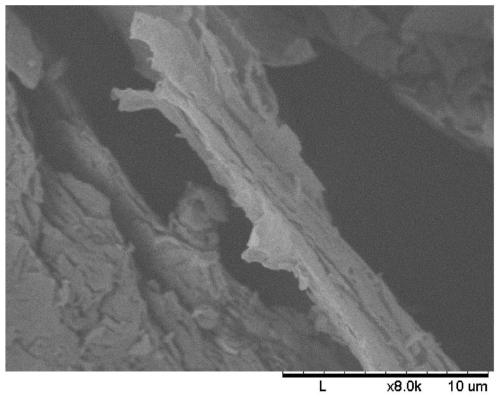

[0030] The high-density FOX-7 base composite material prepared by example 1 is carried out scanning electron microscope (SEM) observation, scanning electron microscope result is as follows figure 2 and image 3 shown. It can be seen from the figure that the FOX-7 crystal has a good degree of recombination, no single two-dimensional conjugated material body is found, and the crystal structure is dense and the plane shape is obvious.

[0031] The high-density FOX-7 based composite material prepared in Example 1 is subjected to vacuum density analysis by gas displacement method, and the density test result is 1.9826g / cm 3 .

Embodiment 2

[0033] Weigh 0.36g of triaminoguanidine hydrochloride and 0.96g of FOX-7, add 13mL of thionyl chloride to the reactant (at this time the solute concentration is 102mg / mL), heat to 70°C to mix the reactant evenly ; 0.58g of formaldehyde solution was added to the above-mentioned hot solution, and after stirring and reacting at 100rpm for 120 minutes, a mixed solution was obtained; 13mL of deionized water was added to the mixed solution to precipitate the product; finally, the product was filtered, washed with deionized water, and vacuum-dried High-density FOX-7-based composite materials can be obtained with a yield of 96.9%

[0034] The high-density FOX-7 composite material that example 2 prepares adopts gas replacement method to carry out vacuum density analysis, and the density test result is 1.9013g / cm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com