Vinyl sulphone surface initiating aqueous phase anionic polymerization method

A technology of anionic polymerization and vinyl sulfone, which is applied in the field of anionic polymerization initiated on the surface of materials, and in the field of aqueous phase anionic polymerization initiated on the surface of vinyl sulfone, which can solve the complex preparation process of dithioesters, limited scope of application of substrates, and increased toxicity of polymers and other problems, to achieve the effect of less background reaction, easy operation, and less monomer loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: take gold as substrate, prepare gold-polymethacrylic acid sulfobetaine (pSBMA) composite material

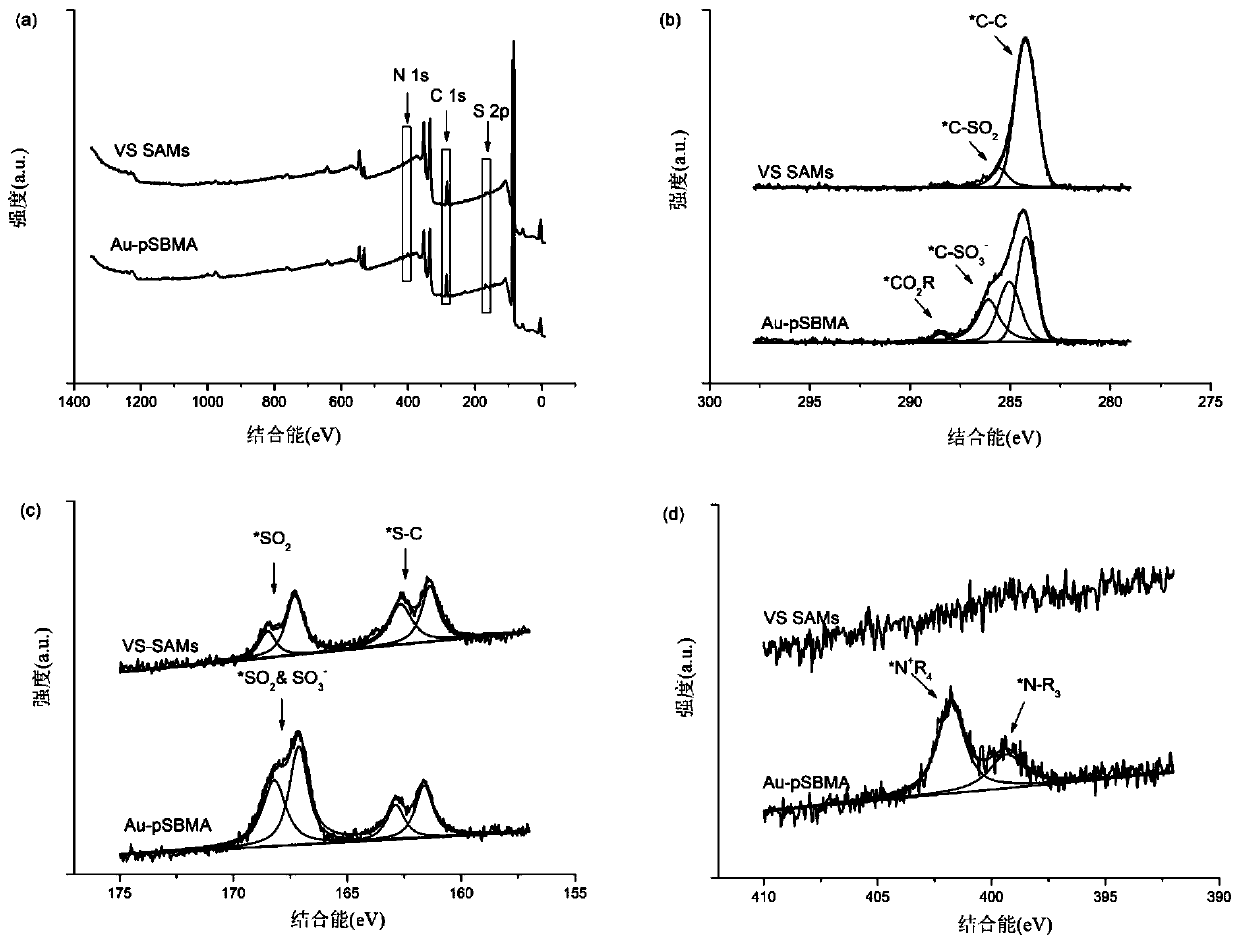

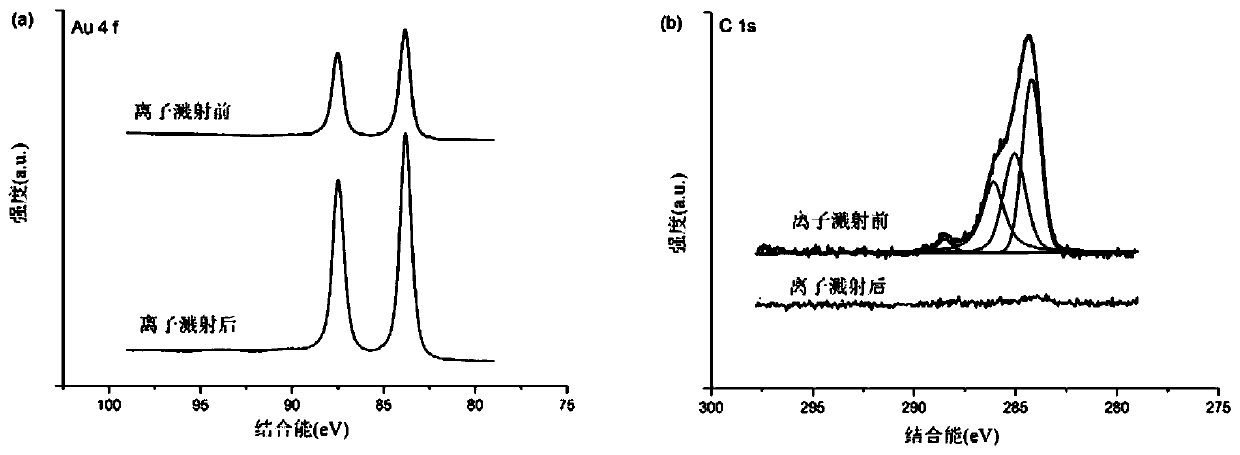

[0041] Cut the gold-plated silicon wafer into 1cm×1cm samples, treat the samples with UV / ozone for 30 minutes, ultrasonically clean them with ethanol for 3 times, and then immerse them in carbon dichloride of 11,11-divinyl sulfone undecyl disulfide compound Self-assembled in solution (1mmol / L) for 12 hours, washed three times with dichloromethane and then dried with nitrogen to prepare self-assembled membranes (VSSAMs) containing vinyl sulfone groups on the surface. Submerge the VSSAMs sample in sulfobetaine methacrylic acid (SBMA) monomer solution (100mmol / L, HEPES buffer containing 5mmol / L 1-methylimidazole), react at 37°C for 12h, take out the sample, and wash 3 times with water Then blow dry with nitrogen. Characterization using X-ray photoelectron spectroscopy (XPS), such as figure 1 shown. After the polymerization was initiated on the surface, the C...

Embodiment 2

[0042] Embodiment 2: take silicon chip as substrate, prepare silicon-polymethacrylic acid sulfobetaine (pSBMA) composite material

[0043] Place the silicon wafer in hot piranha washing solution (volume ratio of concentrated sulfuric acid: 30% hydrogen peroxide = 3:7) for 4 hours, ultrasonically clean it with ultrapure water for 3 times, and dry it with nitrogen to prepare a silicon wafer with hydroxyl groups on the surface. (Si-OH). Then place Si-OH in anhydrous toluene and add (3-mercaptopropyl)trimethoxysilane with a volume fraction of 3%. After ultrasonic cleaning for 2 times, the silicon wafer (Si-SH) with mercapto groups on the surface was prepared by drying with nitrogen gas. Then place Si-SH in divinyl sulfone solution (100mmol / L, HEPES buffer, pH8.0, containing 10% chromatographic acetonitrile to help dissolve), react at 25°C for 1 hour, wash with ultrapure water twice, nitrogen Blow dry to prepare a silicon wafer (Si-VS) containing vinyl sulfone groups on the surfa...

Embodiment 3

[0044] Example 3: Using gold as a substrate to prepare a gold-polydimethylacrylamide composite material

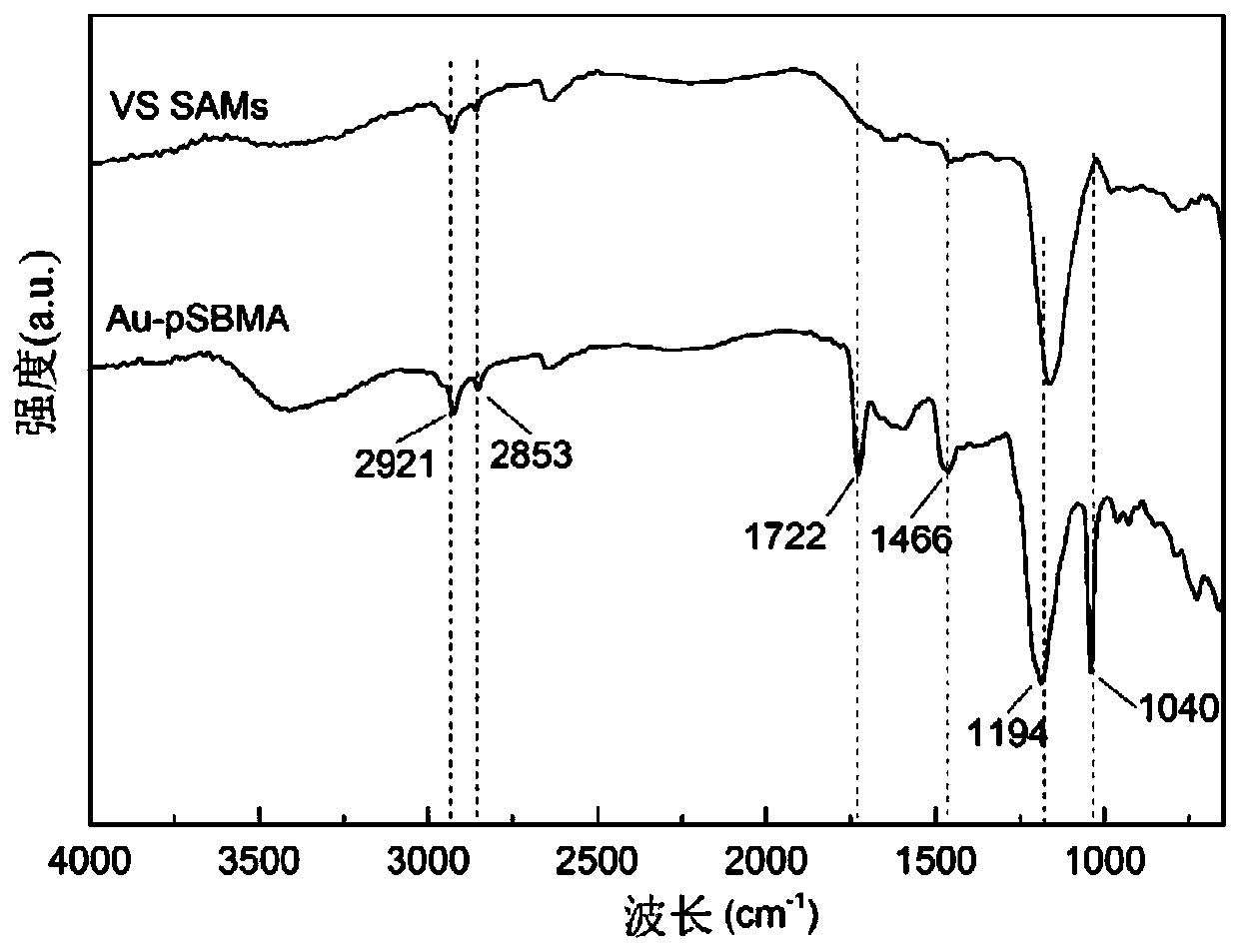

[0045] Cut the gold-plated silicon wafer into 1cm×1cm samples, treat the samples with UV / ozone for 30 minutes, ultrasonically clean them with ethanol for 3 times, and then immerse them in carbon dichloride of 11,11-divinyl sulfone undecyl disulfide compound Self-assembled in solution (1mmol / L) for 12 hours, washed three times with dichloromethane and then dried with nitrogen to prepare self-assembled membranes (VSSAMs) containing vinyl sulfone groups on the surface. Submerge the VSSAMs sample in N,N-dimethylacrylamide monomer solution (100mmol / L, HEPES buffer, containing 5mmol / L triethylenediamine), react at 37°C for 48h, take out the sample, wash it with water three times Blow dry with nitrogen. Characterization using infrared, such as Image 6 shown. After the polymerization is initiated on the surface, the characteristic peak corresponding to the polymer can be clear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com