Metal porphyrin polystyrene elastomer and preparation method and application thereof

A polystyrene and elastomer technology, which is applied in the field of metalloporphyrinated polystyrene elastomer and its preparation, can solve the problems of serious pollution, high energy consumption in the preparation process, and high cost of inorganic photoelectric materials, and achieves a wide range of sources. , low cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation of organic photoelectric material of the present invention:

[0050] (1) Para-chloromethylation of benzene ring

[0051] Dissolve polystyrene elastomer in chloroform solvent, use 1,4-dichloromethoxybutane as chloromethylation reagent, under the catalysis of tin tetrachloride, ice-water bath for several hours, react to obtain chloromethylation Based polystyrene elastomer. The chloromethyl grafting ratio increases with the prolongation of the reaction time, and different chloromethyl grafting ratios can be obtained by controlling different reaction times.

[0052] (2) para-formylation of benzene ring

[0053] Dissolve the chloromethylated polystyrene elastomer in xylene solvent, use DMSO as a mild oxidant, add potassium iodide and sodium bicarbonate, and react at 110°C for 6 hours to obtain the aldylated polystyrene elastomer. The added amount of the formylation reagent is all in excess of the theoretically calculated value to ensure that all chlorometh...

Embodiment 1

[0058] Example 1 Metalloporphyrinated polystyrene elastomer organic photoelectric material of the present invention

[0059] 1. Preparation of Metalloporphyrinated Polystyrene Elastomer Organic Optoelectronic Materials

[0060]

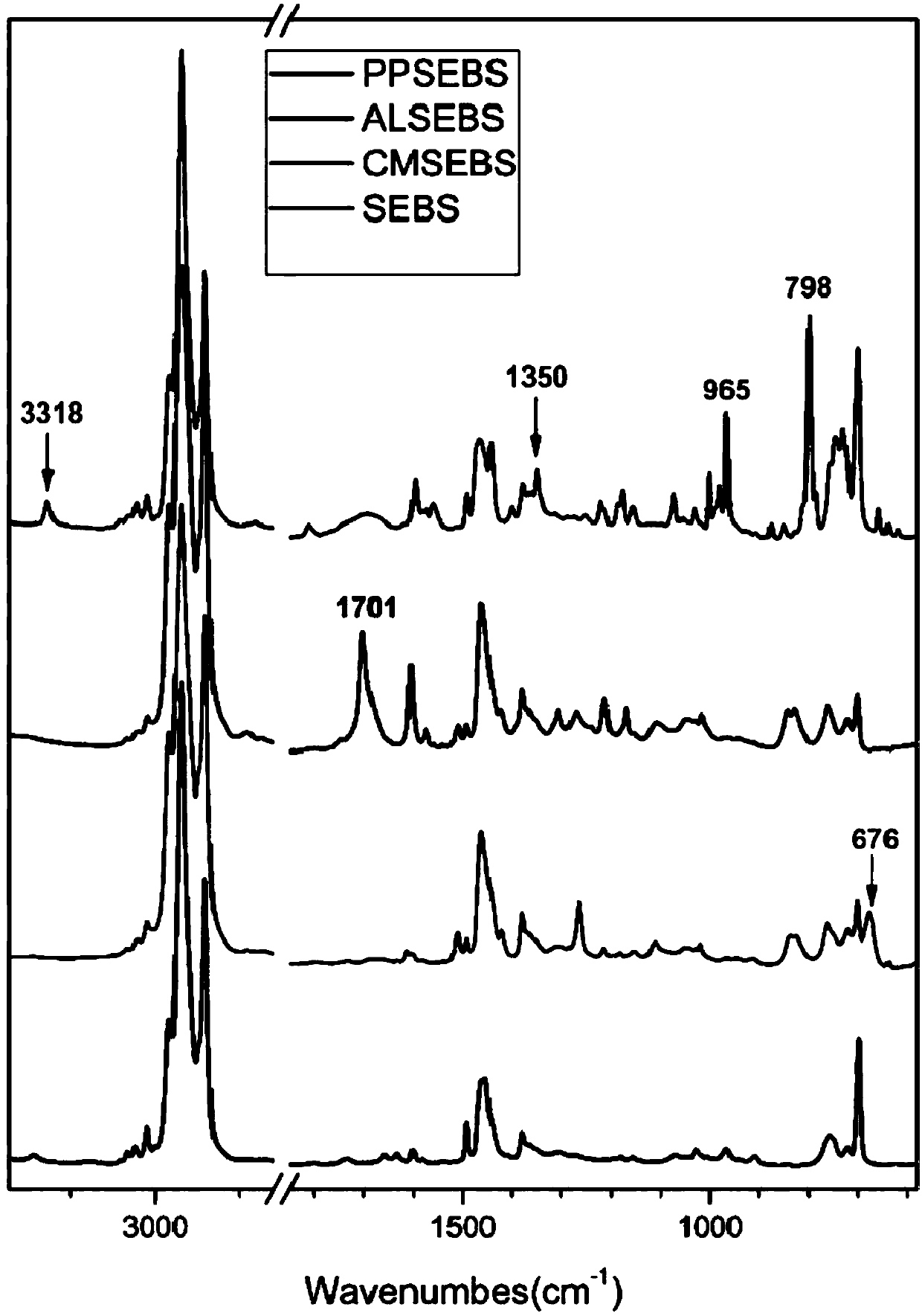

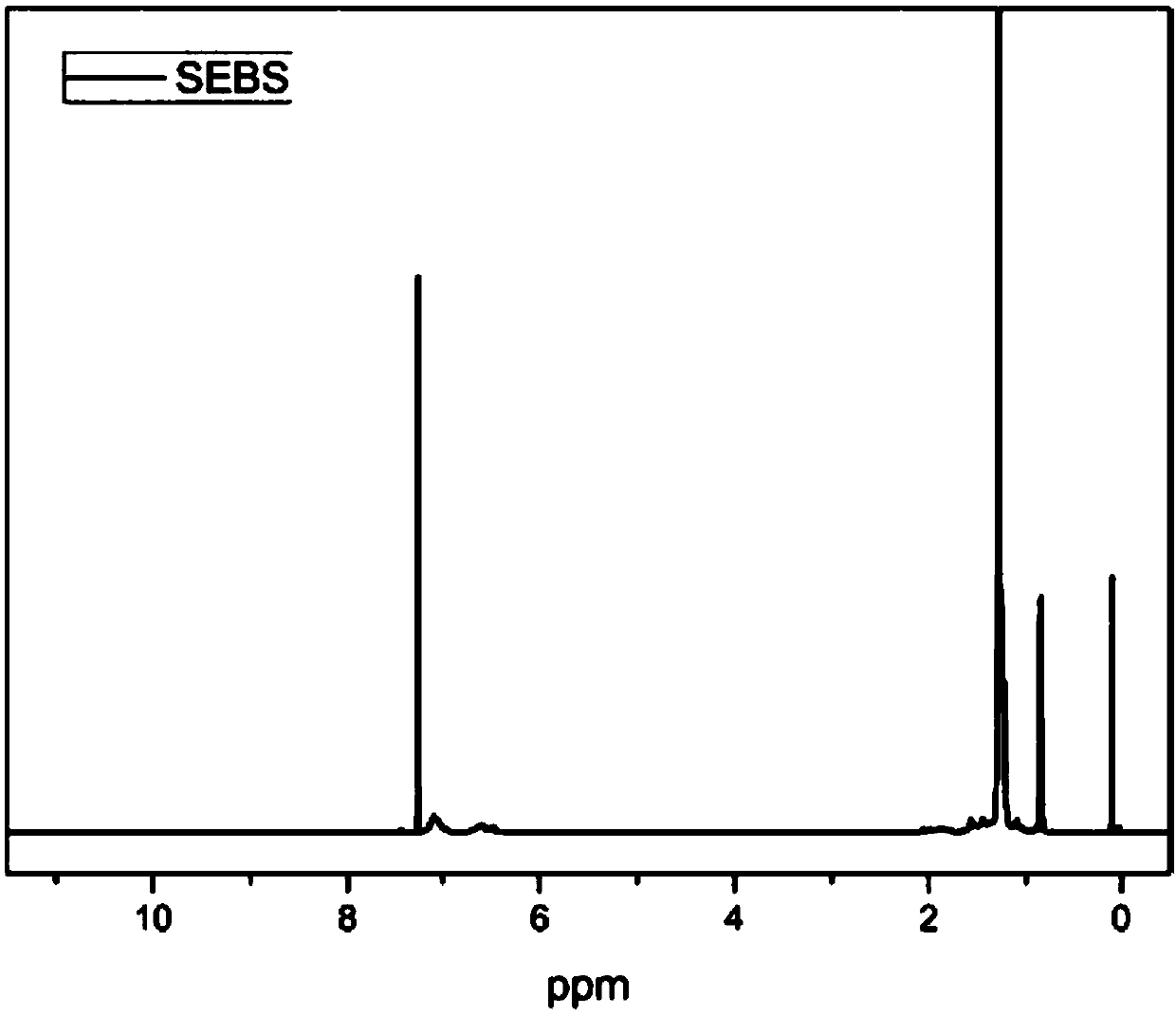

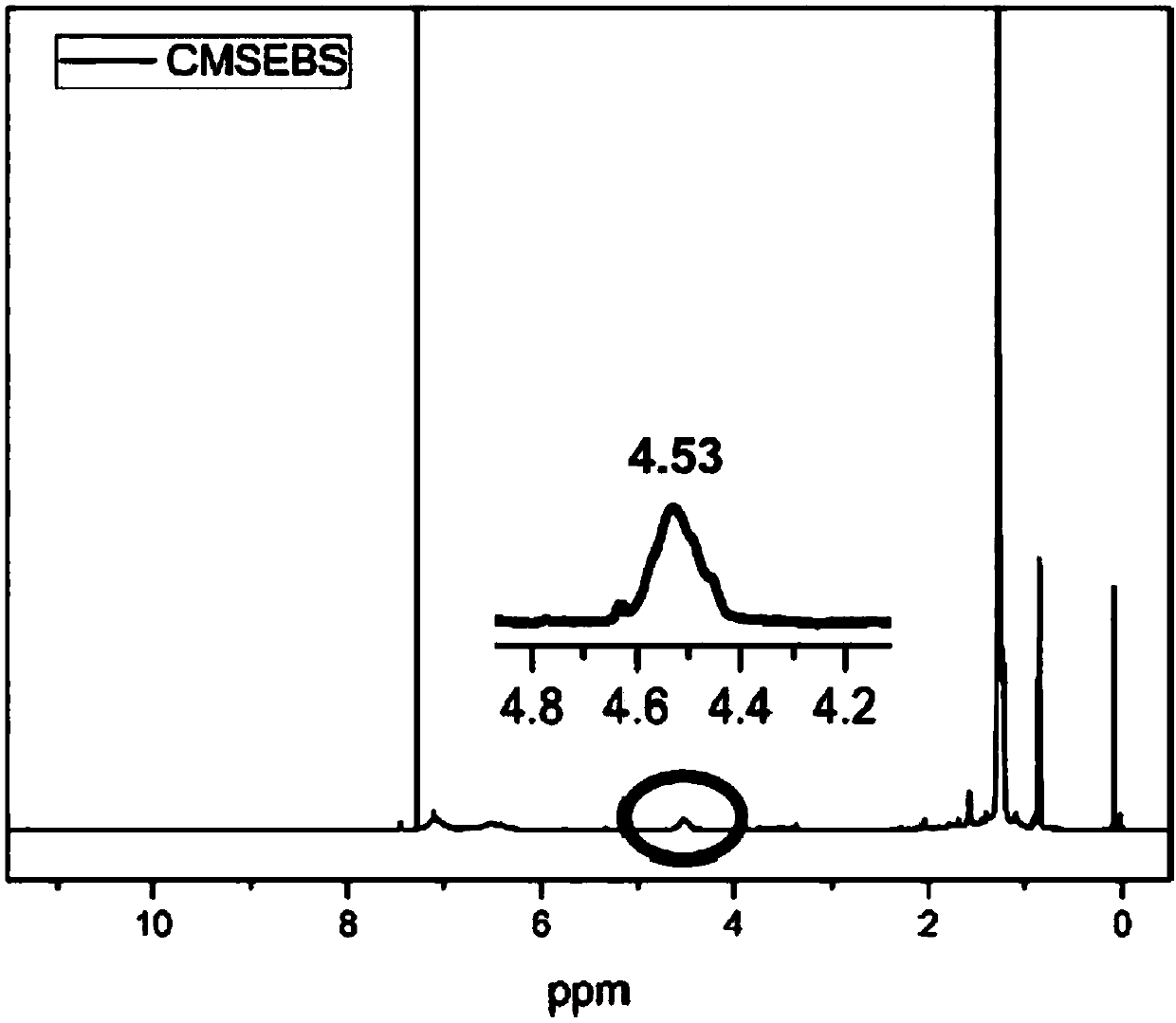

[0061] (1) Para-chloromethylation of SEBS benzene ring to produce CMSEBS

[0062] 5.0g of hydrogenated styrene-butadiene block copolymer (SEBS) (molecular weight 50,000) was dissolved in 250ml of chloroform solvent, with 20ml of 1,4-dichloromethoxybutane as chloromethylation reagent, in Under the catalysis of 4ml of tin tetrachloride, 1.5h in ice-water bath, react to obtain chloromethylated SEBS, denoted as CMSEBS.

[0063] (2) Para-formylation of benzene ring to prepare ALSEBS

[0064] Dissolve 3.0g of CMSEBS in 150ml of xylene solvent, use 50ml of DMSO as a mild oxidizing agent, add 2.0g of potassium iodide and 1.5g of sodium bicarbonate, and react at 110°C for 6h to obtain aldylated SEBS, which is denoted as ALSEBS.

[0065] (3) Porphyrinatio...

Embodiment 2

[0084] Embodiment 2 The organic photoelectric material of the present invention

[0085] 1. Preparation of organic optoelectronic material PPSEBS

[0086] (1) Para-chloromethylation of SEBS benzene ring to produce CMSEBS

[0087] 5.0g of hydrogenated styrene-butadiene block copolymer (SEBS) (molecular weight 50,000) was dissolved in 250ml of chloroform solvent, with 20ml of 1,4-dichloromethoxybutane as chloromethylation reagent, in Under the catalysis of 4ml of tin tetrachloride, in an ice-water bath for 4 hours, the chloromethylated SEBS was obtained, which was denoted as CMSEBS.

[0088] (2) Para-formylation of benzene ring to prepare ALSEBS

[0089] Dissolve 3.0g of CMSEBS in 150ml of xylene solvent, use 50ml of DMSO as a mild oxidizing agent, add 2.0g of potassium iodide and 1.5g of sodium bicarbonate, and react at 110°C for 6h to obtain aldylated SEBS, which is denoted as ALSEBS.

[0090] (3) Porphyrination to produce PPSEBS

[0091] Dissolve 1.0g of ALSEBS in 100ml o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density value | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Current density value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com