Preparation method of porous resin fiber with orientation hole structure, product and application

A technology of porous resin and pore structure, applied in the chemical characteristics of fibers, textiles and papermaking, dry spinning, etc., can solve the problems of increasing the cost of porous materials, high hydrophilicity, low strength, etc. Strength, simple effect of preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

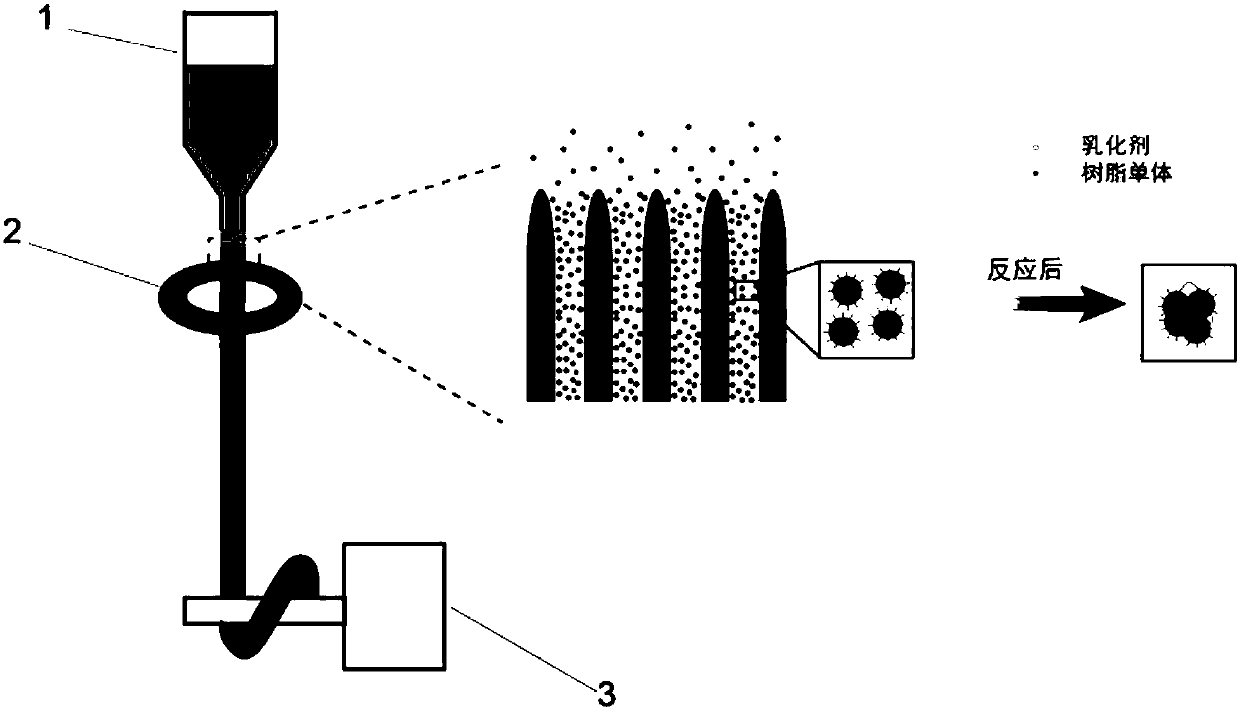

[0040] (1) Dissolve 0.15g of benzoyl peroxide in 6ml of methyl methacrylate and mix evenly. Dissolve 0.7g of ER-10 in 14ml of deionized water and mix evenly to prepare a solution with a mass fraction of 5% ER-10. Mix the above methyl methacrylate mixed solution with the ER-10 solution evenly to form a 30% methyl methacrylate emulsion.

[0041] Add 1.2 g of crosslinking agent ethylene glycol dimethacrylate to the above emulsion, and mix well. Add 0.8 g of nanoclay to the above methyl methacrylate emulsion and mix well. Add 70 μl of N,N-dimethylbenzamide to the above emulsion and mix well, then centrifuge to remove air bubbles.

[0042] (2) Put the above-mentioned emulsion in a syringe, squeeze out the emulsion through an extrusion pump, place the copper ring in a low-temperature reaction bath (-100°C), pass the emulsion through the copper ring for freezing-spinning process, and freeze the frozen The fibers are collected with a motor.

[0043] (3) Place the collected fibers in...

Embodiment 2

[0047] (1) Dissolve 0.15g of benzoyl peroxide in 6ml of methyl methacrylate and mix evenly. Dissolve 0.7g of ER-10 in 14ml of deionized water and mix evenly to prepare a solution with a mass fraction of 5% ER-10. Mix the above methyl methacrylate mixed solution with the ER-10 solution evenly to form a 30% methyl methacrylate emulsion.

[0048] Add 1.2 g of crosslinking agent ethylene glycol dimethacrylate to the above emulsion, and mix well. Add 0.8 g of nanoclay to the above methyl methacrylate emulsion and mix well. Add 70 μl of N,N-dimethylbenzamide to the above emulsion and mix well, then centrifuge to remove air bubbles.

[0049] (2) Put the above-mentioned emulsion in a syringe, squeeze out the emulsion through an extrusion pump, place the copper ring in a low-temperature reaction bath (-100°C), pass the emulsion through the copper ring for freezing-spinning process, and freeze the frozen The fibers are collected with a motor.

[0050] (3) Place the collected fibers ...

Embodiment 3

[0054] (1) Dissolve 0.10g of benzoyl peroxide in 4ml of methyl methacrylate and mix evenly. Dissolve 0.8g of ER-10 in 16ml of deionized water and mix it evenly to prepare an ER-10 solution with a mass fraction of 5%. Mix the above methyl methacrylate mixture with the ER-10 solution evenly to form a 20% methyl methacrylate emulsion.

[0055] Add 0.8 g of cross-linking agent ethylene glycol dimethacrylate to the above emulsion, and mix well. Add 0.53g of nanoclay to the above methyl methacrylate emulsion and mix well. Add 50 μl of N,N-dimethylbenzamide to the above emulsion and mix well, then centrifuge to remove air bubbles.

[0056] (2) Put the above-mentioned emulsion in a syringe, squeeze out the emulsion through an extrusion pump, place the copper ring in a low-temperature reaction bath (-100°C), pass the emulsion through the copper ring for freezing-spinning process, and freeze the frozen The fibers are collected with a motor.

[0057] (3) Place the collected fibers in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com