Preparation method of graded pore activated coke with needle-shaped mesoporous channel and application of graded pore activated coke in flue gas desulfurization

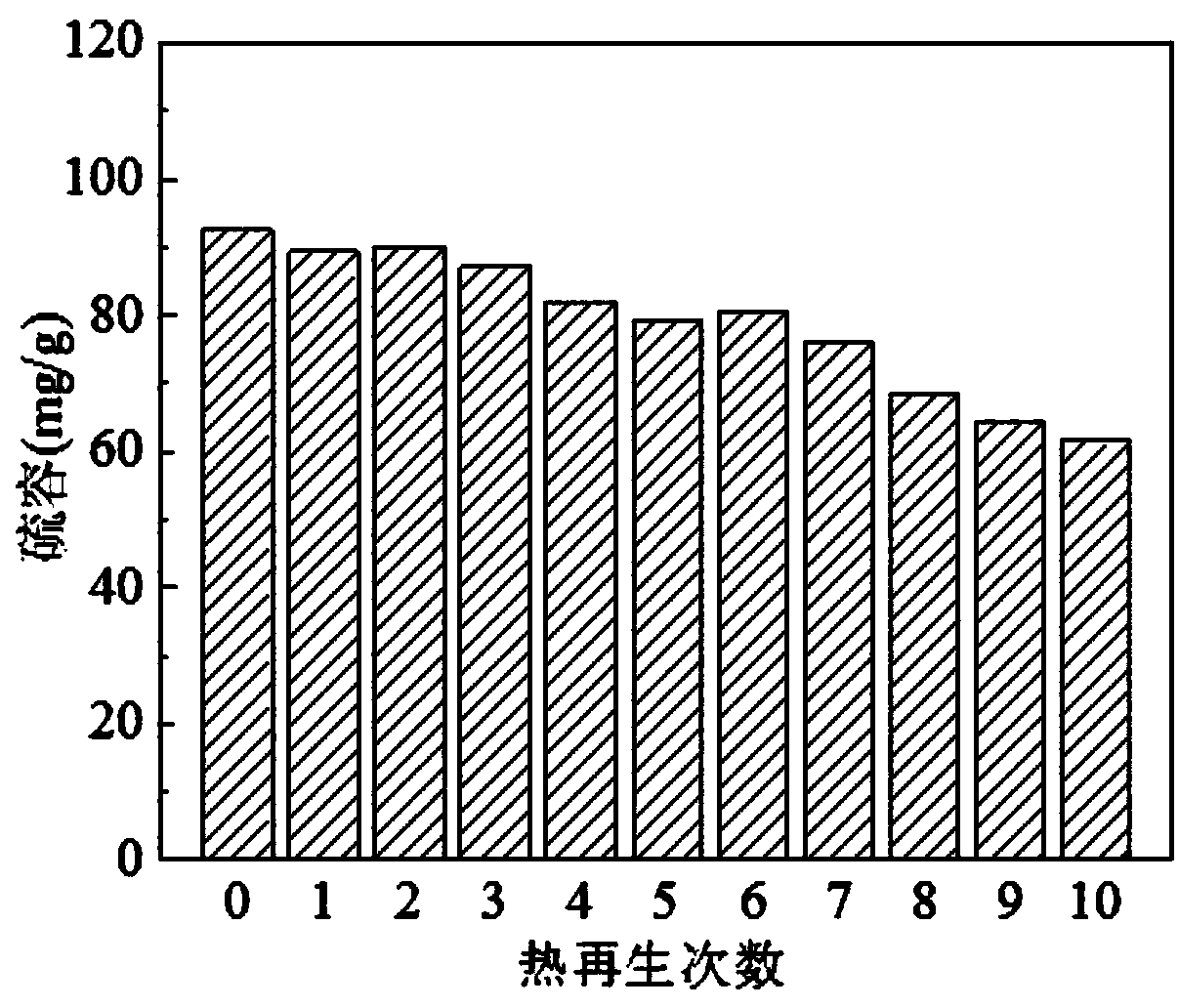

A technology of activated coke and pore channels, applied in the field of activated carbon, can solve the problems of ink bottle-shaped pores, complicated operation, difficult to apply on a large scale, etc., and achieve the effects of increasing the number of cycles, improving the adsorption rate, and high thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

[0036] In the embodiment of the present invention, the Zhundong coal in the low-rank coal (that is, the coal of low degree of metamorphism) is used as the pulverized coal raw material, as shown in the following table:

[0037]

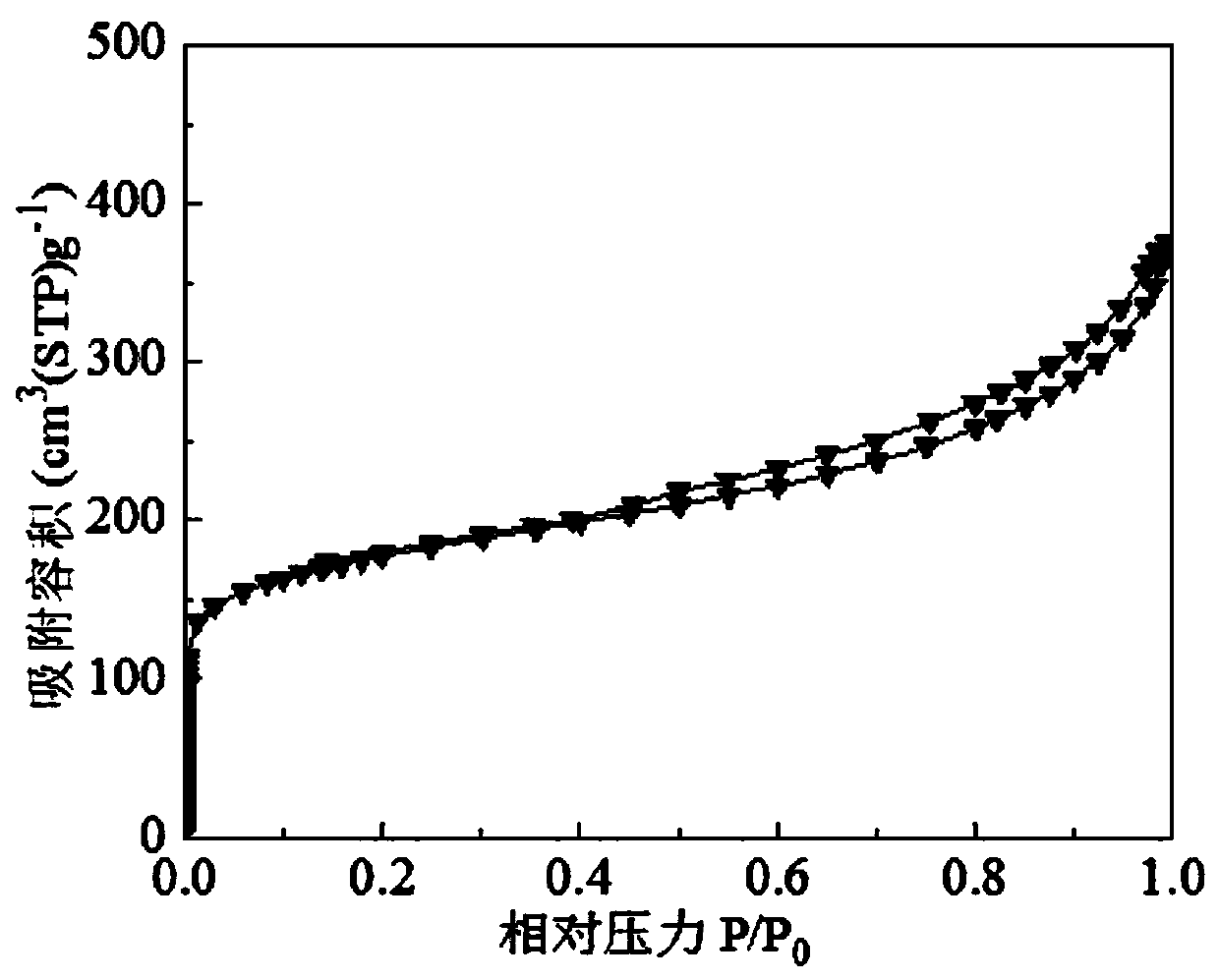

[0038] Micromeritics company ASAP2020 surface area and pore structure analyzer was used to analyze the pore volume of the sample: first, the test sample was put into a degassing station, degassed at 473K for 8 hours under vacuum, and then analyzed, with high-purity N 2 As the adsorbate, at the temperature of liquid nitrogen (77.3K), measure the relative pressure (P / P 0 )10 -7 Adsorption and desorption isotherms in the range of ~1; the liquid nitrogen volume is calculated from the liquid nitrogen adsorption value at a relative pressure of 0.98 as the total pore volume, and the micropore volume is calculated using the DR...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com