Composite chromatography filtering membrane material based on nanofibers and polymer microspheres and preparation method of composite chromatography filtering membrane material

A nanofiber and polymer technology, which is applied in the field of composite chromatography filtration membrane materials based on nanofibers and polymer microspheres and their preparation, can solve the problem of large differences in size and structure between inorganic micron active particles and nanofibers, and water treatment retention. It can solve the problems of poor efficiency and retention stability, and it is difficult to achieve the optimal pore structure of membrane materials, so as to achieve excellent cation adsorption, improve chromatography efficiency and filtration-chromatography stability, and improve filtration stability and filtration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A kind of preparation method of the composite chromatographic filtration membrane material based on nanofiber and polymer microsphere provided by the present invention comprises the following steps:

[0039] S1. Mix PVA-co-PE nanofibers and sulfonated polymer microspheres according to a preset mass ratio to prepare a suspension; wherein, the particle size and mass of the sulfonated polymer microspheres are respectively greater than or equal to PVA-co-PE The diameter and mass of nanofibers; preferably, the preset mass ratio of nanofibers and sulfonated polymer microspheres is 1:(1-4), more preferably 1:(1.5-3), more preferably 1:2 . The solvent of the suspension is a mixed solvent of ethanol and water, preferably ethanol and water with a volume ratio of 1:1. The present invention selects PVA-co-PE nanofibers and sulfonated polymer microspheres to make composite membranes. On the one hand, both of them have hydrophilic groups and good compatibility, which is convenient f...

Embodiment 1-3

[0061] A method for preparing a composite chromatographic filtration membrane material based on nanofibers and polymer microspheres, comprising the following steps:

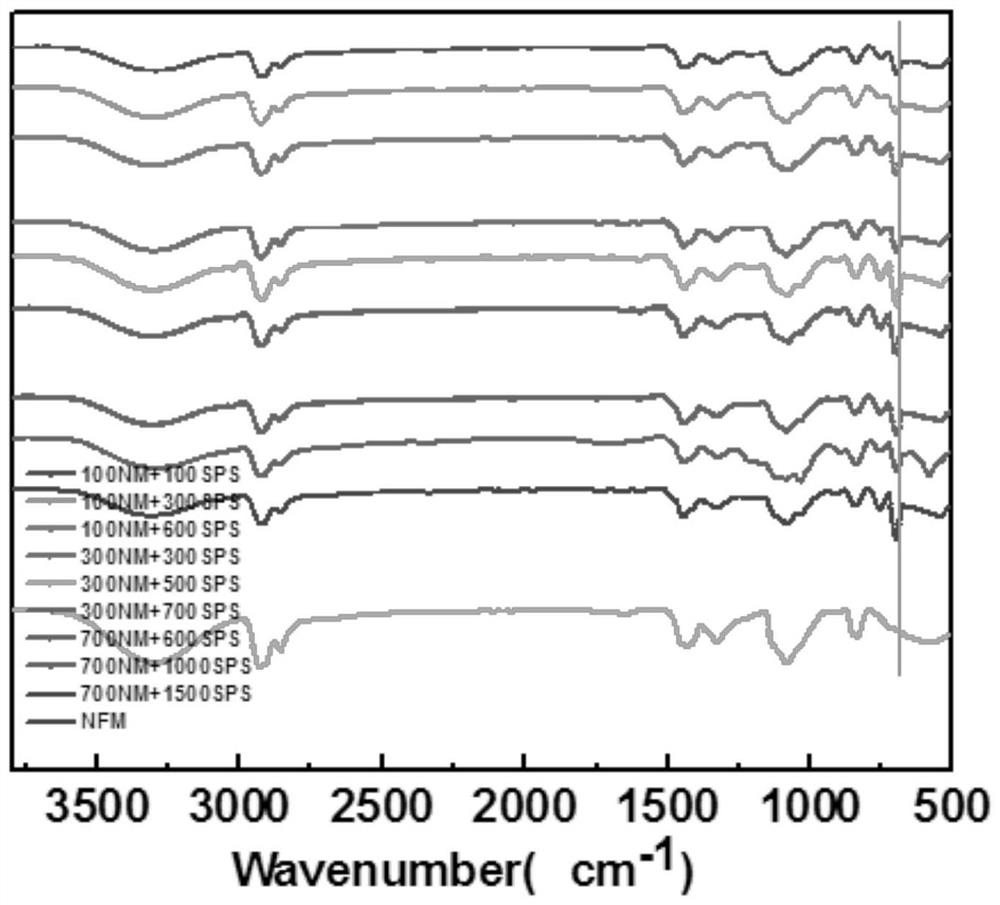

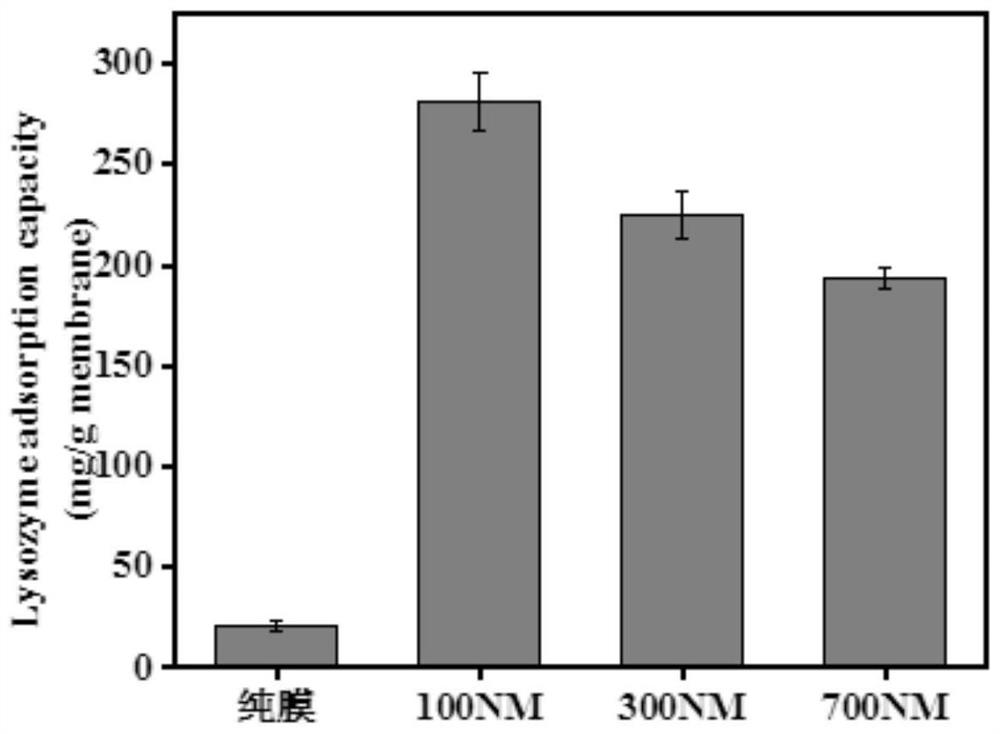

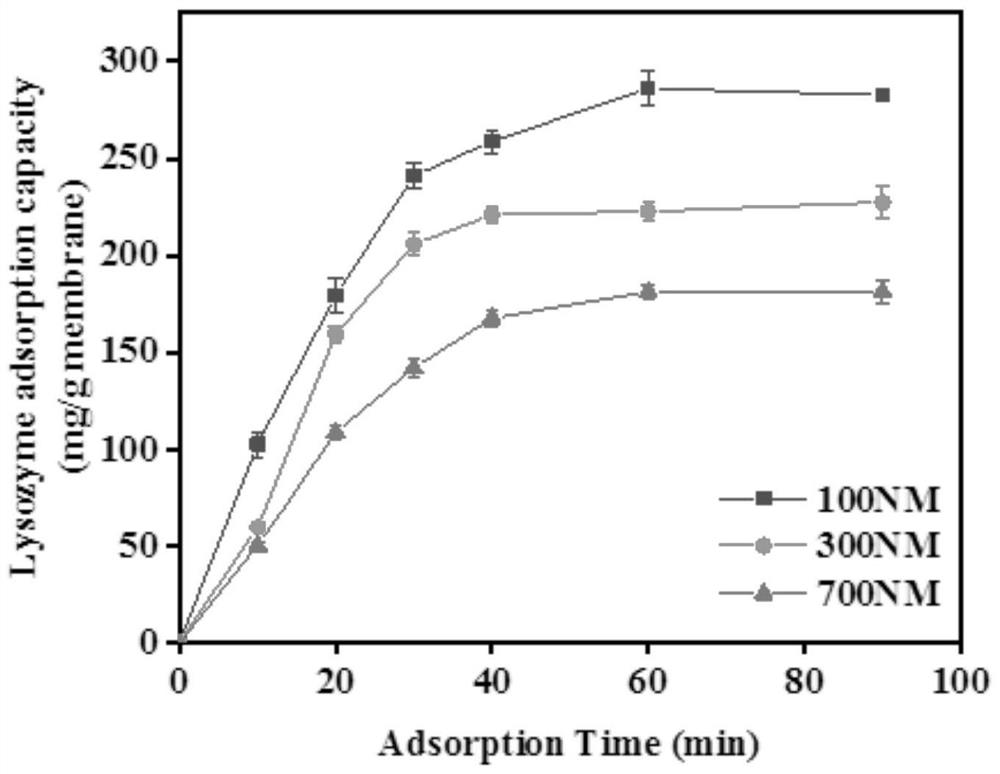

[0062] PVA-co-PE and cellulose acetate butyrate (CAB) were blended and spun to produce 100nm PVA-co-PE nanofibers by melt spinning phase separation method, and 12g of 100nm PVA-co-PE nanofibers were taken. Take by weighing the 100nm sulfonated polystyrene microsphere solution of different quality according to table 1, be dissolved in 1L water and the ratio of ethanol is in the mixed solution of 1:1, then the 100nmPVA-co-PE nanofiber of 12g is dispersed in respectively The mixture is configured as a 12g / L suspension. The gram weight is 50g / m 2 On the PP spunbond cloth, uniform coating 6g / m 2 100nm PVA-co-PE nanofibers, after drying at room temperature, the filter layer is 6g / m 2 Composite membrane filter material of nanofibers and sulfonated microspheres. see figure 1 As shown, it shows that the composite mem...

Embodiment 2

[0069] From Figure 5 It can be seen that after adding sulfonated microspheres, the pore size of the fiber membrane decreases, and the more the amount of sulfonated microspheres is added, the smaller the pore size; it can be seen from Table 1 that although the pore size of Example 2 is reduced to that of Comparative Example 1 In general, but the water flux is not significantly lower than that of Comparative Example 1, so that the filtration efficiency is significantly increased while still maintaining a high water consumption. combine Figure 6 It can be seen that the water flux of the fiber membrane without adding sulfonated microspheres decreases significantly with the increase of filtration time, and drops by about 40% after 30 minutes, indicating that the filtration stability is not good. After a certain period of use, the fiber membrane is blocked . And embodiment 2 drops about 25% after 30min, illustrates that adding sulfonated microspheres helps to improve filtration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com