High attenuation optical fiber and preparation method thereof

A high-attenuation, optical fiber preform technology, applied in the field of optical fiber devices, can solve problems such as differences in attenuation coefficients, and achieve the effects of small change rate, high attenuation flatness, and precise controllable doping amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

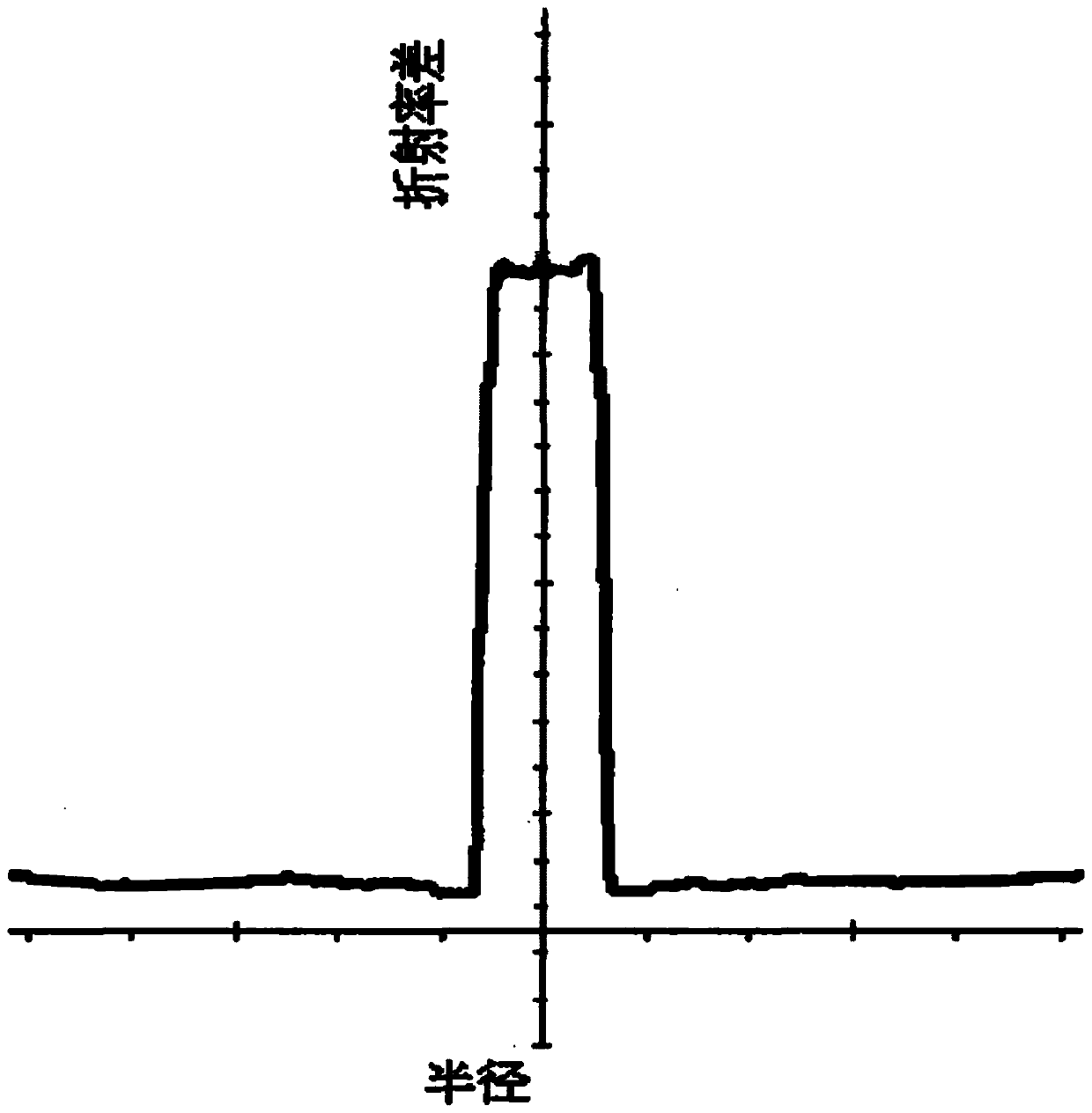

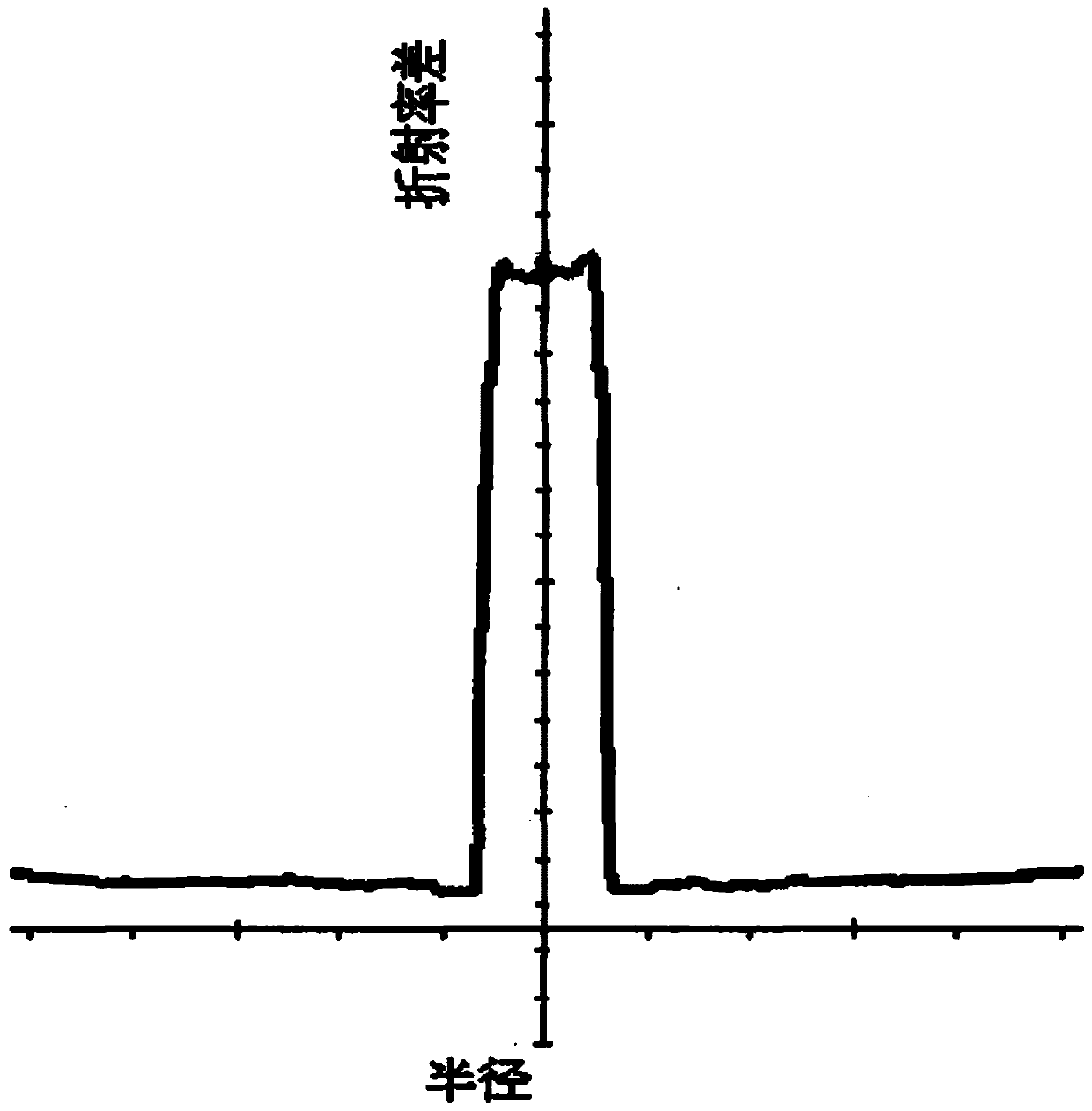

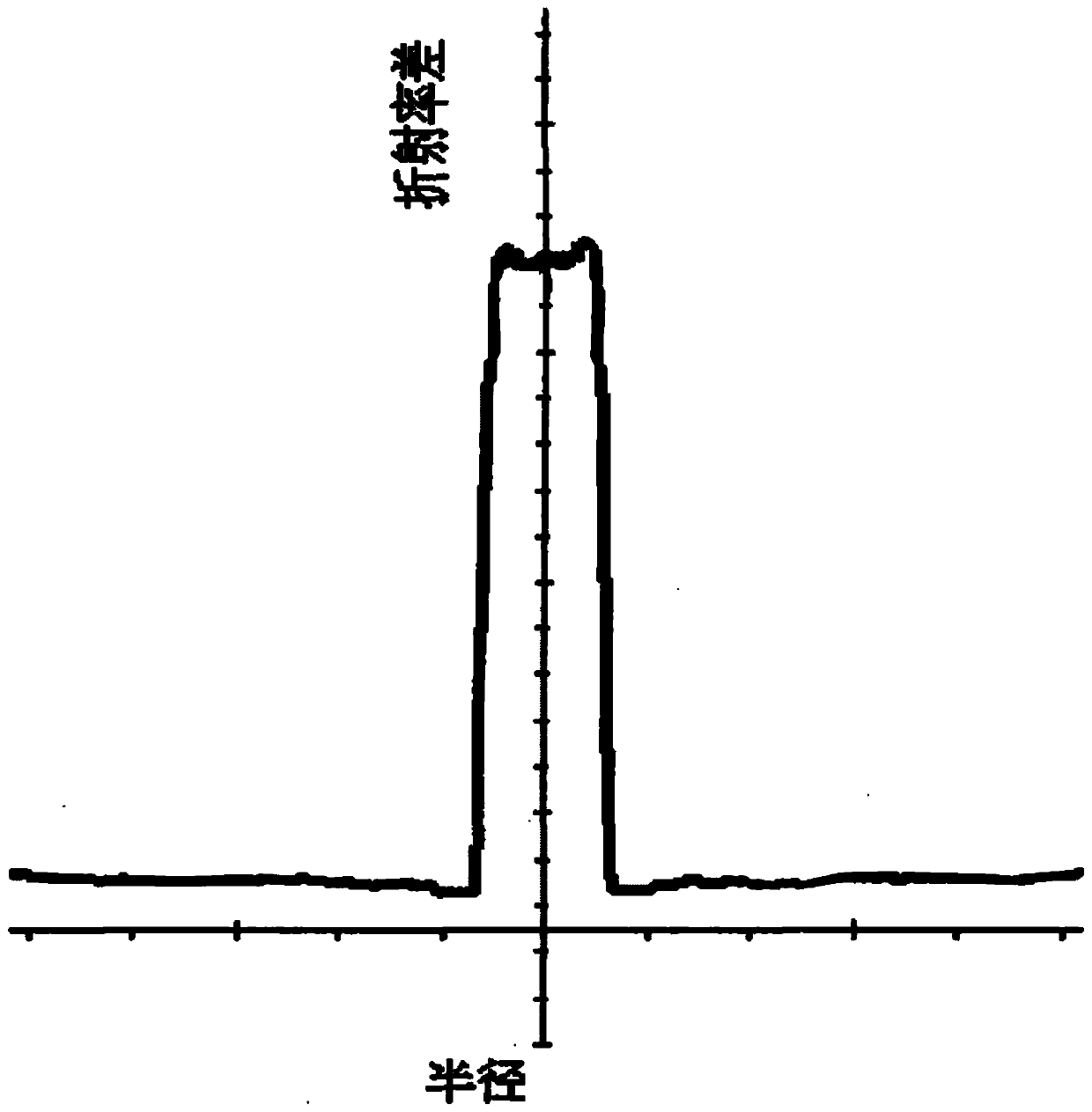

Image

Examples

preparation example Construction

[0052] The preparation method of the high-attenuation optical fiber provided by the present invention comprises the following steps:

[0053] (1) Mix the first phase containing the metal element in the formula ratio with the second phase mainly composed of loose quartz glass powder and make a uniform solid phase; wherein the first phase is a liquid phase and / or a solid phase , the density of the quartz glass powder is 0.3~1.1g / cm 3 .

[0054] Preferably, the first phase is a liquid phase, which contains two or more of cobalt ions, iron ions, chromium ions, manganese ions, and nickel ions;

[0055] The loose quartz glass powder is prepared by a chemical vapor deposition process, and preferably contains germanium in a formula ratio. Chemical vapor deposition processes include VAD, MCVD or OVD processes.

[0056] The transportation adaptable glass powder prepared by the chemical vapor deposition process is white opaque silica; the quartz glass powder is loose and contains a la...

Embodiment 1

[0069] Using OVD (outside vapor deposition process) to deposit quartz powder, the powder is made of silicon tetrachloride, germanium tetrachloride, O 2 and C 2 f 6 The reaction gas undergoes a chemical reaction under the heating of a heat source such as a hydrogen-oxygen flame to produce an opaque white silica powder with a density of 0.4 to 0.7 g / cm3. Then, take the cobalt, iron, chromium salt of corresponding mass according to the molar ratio, fully dissolve in water or alcohol solution, and then mix with the silicon dioxide powder of corresponding proportion mass and disperse evenly. Then use microwave radiation to heat and remove free water for drying. The microwave radiation time is preferably 0.1 min to 30 min, the microwave frequency range is 1.0 GHz to 2.45 GHz, and the microwave radiation power is 0.5 kW to 10 kW. After drying, fully grind and mix the silica powder absorbed with the metal salt, and then isostatically compress it into a dense powder with a density of...

Embodiment 2

[0072] Using MCVD (improved chemical vapor deposition process) to deposit quartz powder, the powder is made of silicon tetrachloride, germanium tetrachloride, O 2 and C 2 f 6 The reaction gas reacts chemically in the tube under the heating of a heat source such as a hydrogen-oxygen flame, and produces an opaque white silica powder with a density of 0.3 to 0.7 g / cm3. After taking out the powder, weigh the corresponding mass of cobalt, iron, chromium, aluminum salt according to the molar ratio, fully dissolve in water or alcohol solution, and then mix with the corresponding proportion of mass of silica powder and disperse evenly. Then use microwave radiation to heat and remove free water for drying. The microwave radiation time is preferably 0.1 min to 10 min, the microwave frequency range is 1.0 GHz to 2.45 GHz, and the microwave radiation power is 0.5 kW to 5 kW. After drying, fully grind and mix the silica powder absorbed with the metal salt, and then isostatically compress...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com