A novel calcifediol (25-hydroxyvitamin D3) separation and purification method

A hydroxyvitamin and calcifediol technology, applied in the field of bioengineering, can solve the problems of less elaboration of the calcifediol extraction and purification process, difficulty in industrialized scale-up production, high equipment cost and high cost, and achieves strong repeatable operation and equipment. Low cost and high throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

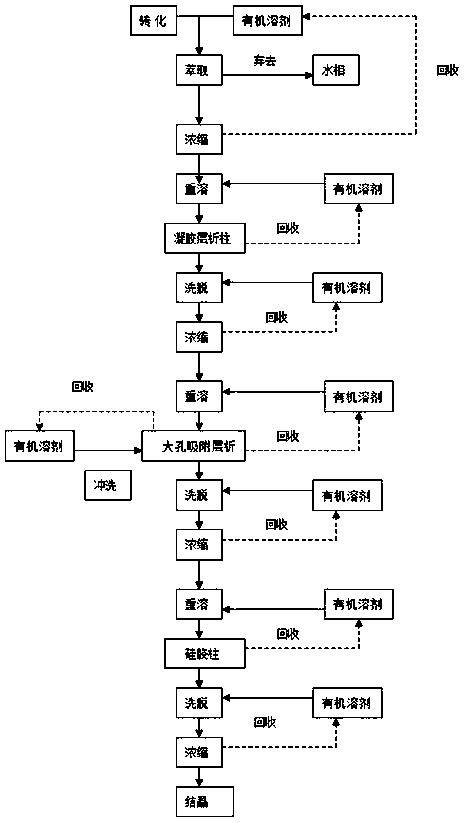

Image

Examples

Embodiment 1

[0032] (1) Vitamin D is catalyzed by microbial enzymes 3 Generate calcifediol (25-hydroxyvitamin D 3 ) into the conversion solution, ethyl acetate was added at a volume ratio of 1:1, extracted by shaking for 1 h, and the organic solvent in the upper layer was collected to obtain calcifediol extract a.

[0033] (2) Concentrate the above calcifediol extract a under reduced pressure, recover ethyl acetate, redissolve the concentrate with methanol, adjust the concentration of calcifediol to 0.5 mg / L, and obtain column solution b.

[0034] (3) After the agarose gel filtration chromatography is activated, the column is packed by a wet method, and the upper column solution b is passed through the agarose gel filtration chromatography column at a flow rate of 2BV / h, and the chromatographic molecular weight is selected to be 400Da. 1BV of ethyl acetate was used as the eluent, and it was eluted at a flow rate of 2BV / h. The eluate was collected, concentrated under reduced pressure at 60...

Embodiment 2

[0036] (1) Vitamin D is catalyzed by microbial enzymes 3 Generate calcifediol (25-hydroxyvitamin D 3 ) into the conversion solution, add ethyl hexanoate at a volume ratio of 1:2, shake and extract for 0.5 h, collect the organic solvent in the upper layer, and obtain calcifediol extract a.

[0037] (2) Concentrate the above calcifediol extract a under reduced pressure, recover ethyl caproate, redissolve the concentrate with methanol, adjust the concentration of calcifediol to 0.8 mg / L, and obtain column solution b.

[0038] (3) After the dextran gel filtration chromatography is activated, the column is packed by a wet method, and the upper column solution b is passed through the dextran gel filtration chromatography column at a flow rate of 2BV / h, and the chromatography molecular weight is selected as 500Da, using 1BV of ethyl acetate as the eluent, eluted it at a flow rate of 2BV / h, and collected the eluate.

[0039] (4), the above-mentioned eluent was concentrated under red...

Embodiment 3

[0042] (1) Vitamin D is catalyzed by microbial enzymes3 Generate calcifediol (25-hydroxyvitamin D 3 ) into the transformation solution, petroleum ether was added at a volume ratio of 1:5, extracted by shaking for 0.5 h, and the organic solvent in the upper layer was collected to obtain calcifediol extract a.

[0043] (2) Concentrate the above calcifediol extract a under reduced pressure, recover petroleum ether, redissolve the concentrate with methanol, adjust the concentration of calcifediol to 1 mg / L, and obtain column solution b.

[0044] (3) After the agarose gel filtration chromatography is activated, the column is packed by a wet method, and the upper column solution b is passed through the agarose gel filtration chromatography column at a flow rate of 2BV / h, and the molecular weight of the chromatography is selected to be 700Da. 1BV of ethyl acetate was used as the eluent, and it was eluted at a flow rate of 2BV / h, and the eluate was collected.

[0045] (4), the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com