Function enhanced metal organic framework-based composite phase change material and preparation method thereof

A technology of metal-organic frameworks and composite phase change materials, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of material thermal conductivity improvement, small thermal conductivity, unevenness, etc., to improve thermal conductivity and heat storage and release The effect of speed and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

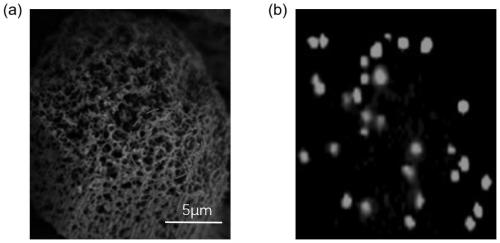

Image

Examples

Embodiment 1

[0030] A function-enhanced metal-organic framework-based composite phase-change material, the preparation of which comprises the following steps:

[0031] Step 1, 0.2g Zn 4 O(BC) 6 , 2.41g copper nitrate trihydrate, 1.70g silver nitrate, and 1.66g terephthalic acid were dissolved in 35mL TMAOH (tetramethylammonium hydroxide), mixed and stirred for 10min, the solution was transferred to a polytetrafluoroethylene reactor, and the temperature was raised to 210°C and react at constant temperature for 24 hours, then cool to room temperature, filter, wash the filtered first filter residue with DMF (N,N-dimethylformamide), then centrifuge, dry and then disperse In hydrochloric acid solution (pH=1), stir for 10 minutes and then filter, wash the filtered second filter residue with DMF again, then centrifuge, dry and then disperse in 30mL acetone, ultrasonically disperse for 30min to make Disperse evenly, then place it under ultraviolet light and stir for 5 hours, filter, wash and dry...

Embodiment 2

[0036] A function-enhanced metal-organic framework-based composite phase-change material, the preparation of which comprises the following steps:

[0037] Step 1. Dissolve 0.2g MOF-5-Cl, 2.41g copper nitrate trihydrate, 1.70g silver nitrate, and 1.66g terephthalic acid in 35mL TMAOH (tetramethylammonium hydroxide), mix and stir for 10min, and dissolve the solution Transfer to a polytetrafluoroethylene reactor, raise the temperature to 210°C and react at a constant temperature for 24 hours, then cool to room temperature, filter, and wash the filtered first filter residue with DMF (N,N-dimethylformamide) before After being centrifuged, dried, and then dispersed in hydrochloric acid solution (pH=1), filtered after stirring for 10 min, the filtered second filter residue was washed again with DMF, and then centrifuged successively. After drying, disperse in 30 mL of acetone, ultrasonically disperse for 30 min to disperse evenly, then place it under ultraviolet light and stir for 5 ...

Embodiment 3

[0041] A function-enhanced metal-organic framework-based composite phase-change material, the preparation of which comprises the following steps:

[0042] Step 1. Dissolve 0.2g ZIF-8, 2.41g copper nitrate trihydrate, 1.70g silver nitrate, and 1.66g terephthalic acid in 35mL TMAOH (tetramethylammonium hydroxide), mix and stir for 10min, and transfer the solution to poly In a tetrafluoroethylene reactor, heat up to 210°C and react at a constant temperature for 24 hours, then cool to room temperature, filter, wash the filtered first filter residue with DMF, then centrifuge, dry, and then disperse in hydrochloric acid solution (pH=1), filter after stirring for 10 min, wash the second filter residue with DMF, then centrifuge it successively, dry and then disperse in 30 mL of acetone, ultrasonically disperse for 30 min to make it disperse evenly, and then Place it under ultraviolet light and stir for 5 hours, filter, wash and dry the filtered third filter residue to obtain a metal o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com