Catalyst with sulfur resistance and function of catalyzing oxidation of NO and preparing method and application of catalyst

A catalytic oxidation and catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as deactivation, achieve simple operation, simple process flow, and no secondary pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The specific surface area is 1200m 2 / g, coconut shell activated carbon with a particle size of 40-60 mesh was placed in a vacuum drying oven, dried at a vacuum degree of -0.6MPa and a temperature of 80°C for 12 hours, and recorded as sample AC.

[0044] Take 5g of sample AC, place it in a porcelain boat, transfer it into a tube furnace, and inject 50mL of N 2 (99.99vol.%), the temperature was raised to 800°C at a rate of 5°C / min, and calcined for 2 hours; then the temperature was lowered to room temperature at a rate of 5°C / min, and the sample was taken out and recorded as AC-800°C.

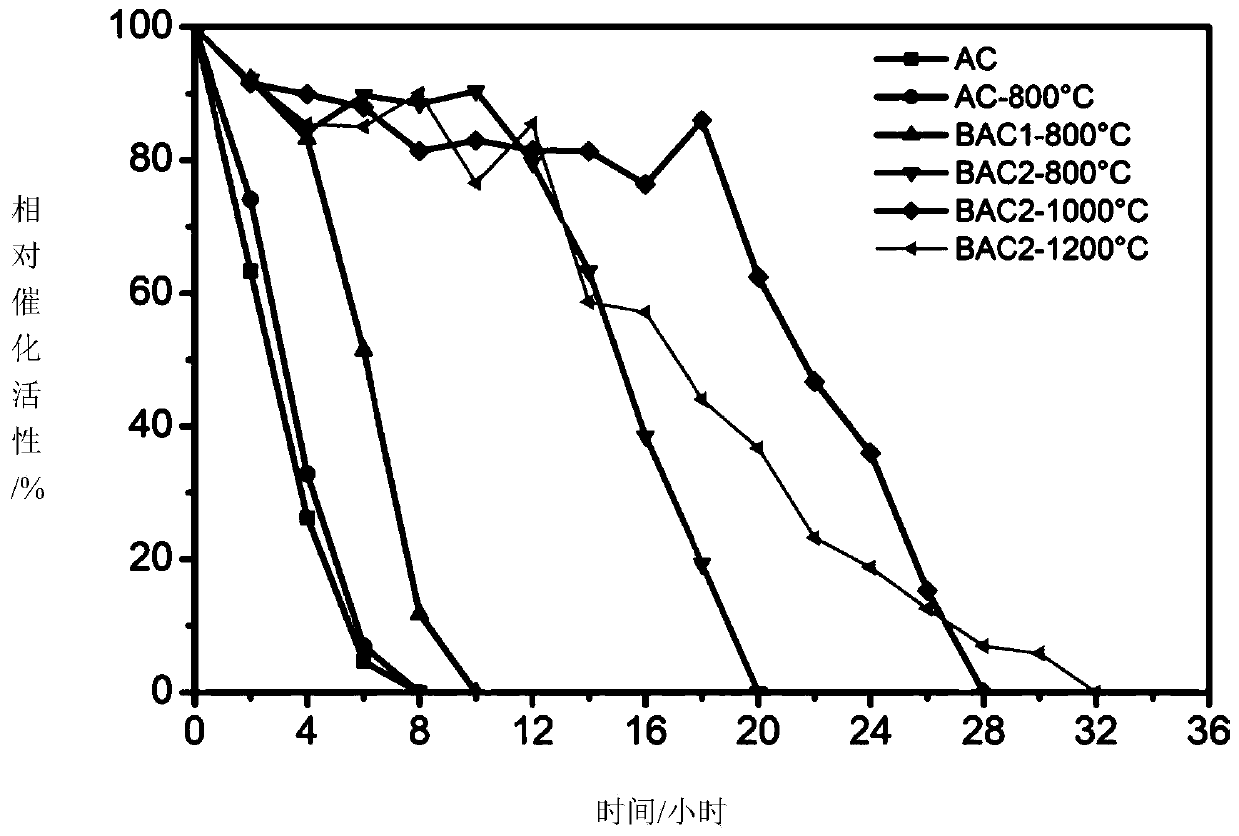

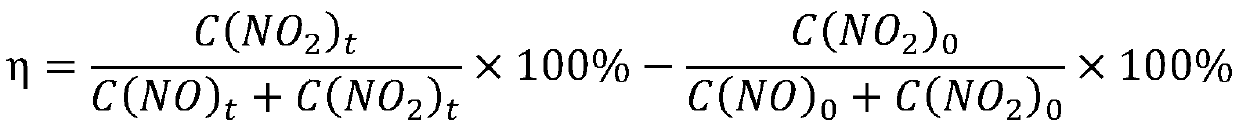

[0045] Sample AC and sample AC-800°C were respectively tested for catalytic oxidation of NO at room temperature in sulfur-containing flue gas. The method is as follows: take 0.300g of the sample and fill it into a quartz reaction tube with an inner diameter of 1cm, and feed 800ppmNO, 20vol .%O 2 , N 2 (99.99vol.%) balanced gas mixture, space velocity 120000h -1 . Measure NO and NO ev...

Embodiment 2

[0050] The specific surface area is 1200m 2 / g, coconut shell activated carbon with a particle size of 40-60 mesh is placed in a vacuum drying oven, and dried at a vacuum degree of -0.6MPa and a temperature of 80°C for 12h. Take 5.00g of dried activated carbon and place it in a flask, add 200mL of 0.15wt.%H 3 BO 3 solution, mix well. The flask was placed in an ultrasonic cleaner and ultrasonically oscillated for 30 minutes at a power of 1000W and a temperature of 30°C, then connected to a rotary evaporator, and evaporated and dried in a water bath at a vacuum of -0.01MPa and a temperature of 80°C to obtain uniformly distributed particles on the surface and in the pores. h 3 BO 3 Activated carbon, placed in a porcelain boat, moved into a tube furnace, and injected with 50mL N 2 (99.99vol.%), raised the temperature to 800°C at a rate of 5°C / min, and calcined for 2h; then cooled to room temperature at a rate of 5°C / min, and took it out to obtain B-doped activated carbon BAC1...

Embodiment 3

[0053] Keep other conditions in Example 1 unchanged, H 3 BO 3 The concentration of the solution was changed to 0.30 wt.%, and the prepared catalyst BAC2%-800°C was evaluated under the same test conditions as in Example 1. The activity time of the catalyst in sulfur-containing flue gas is 20h, such as figure 1 As shown, compared with before modification, it is extended by 150%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com