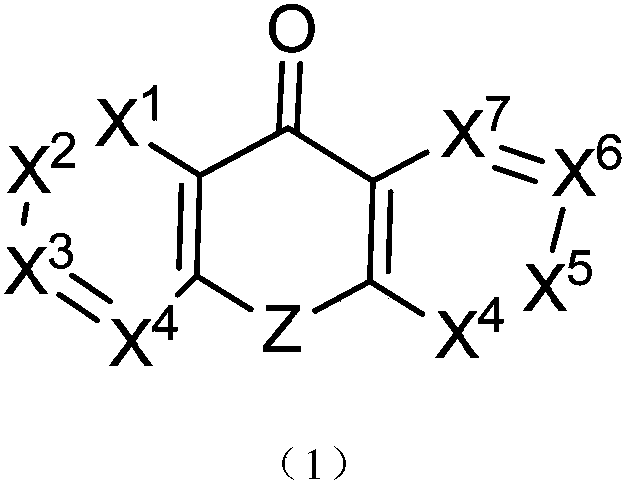

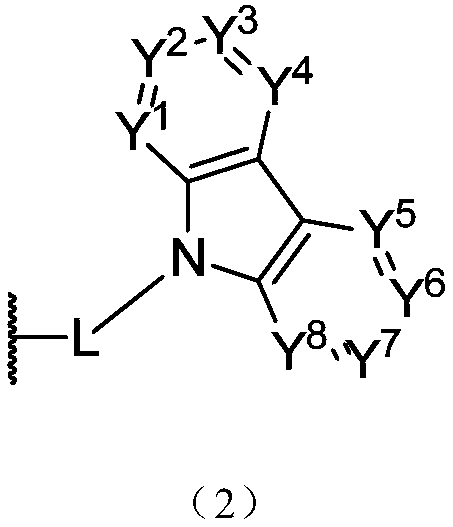

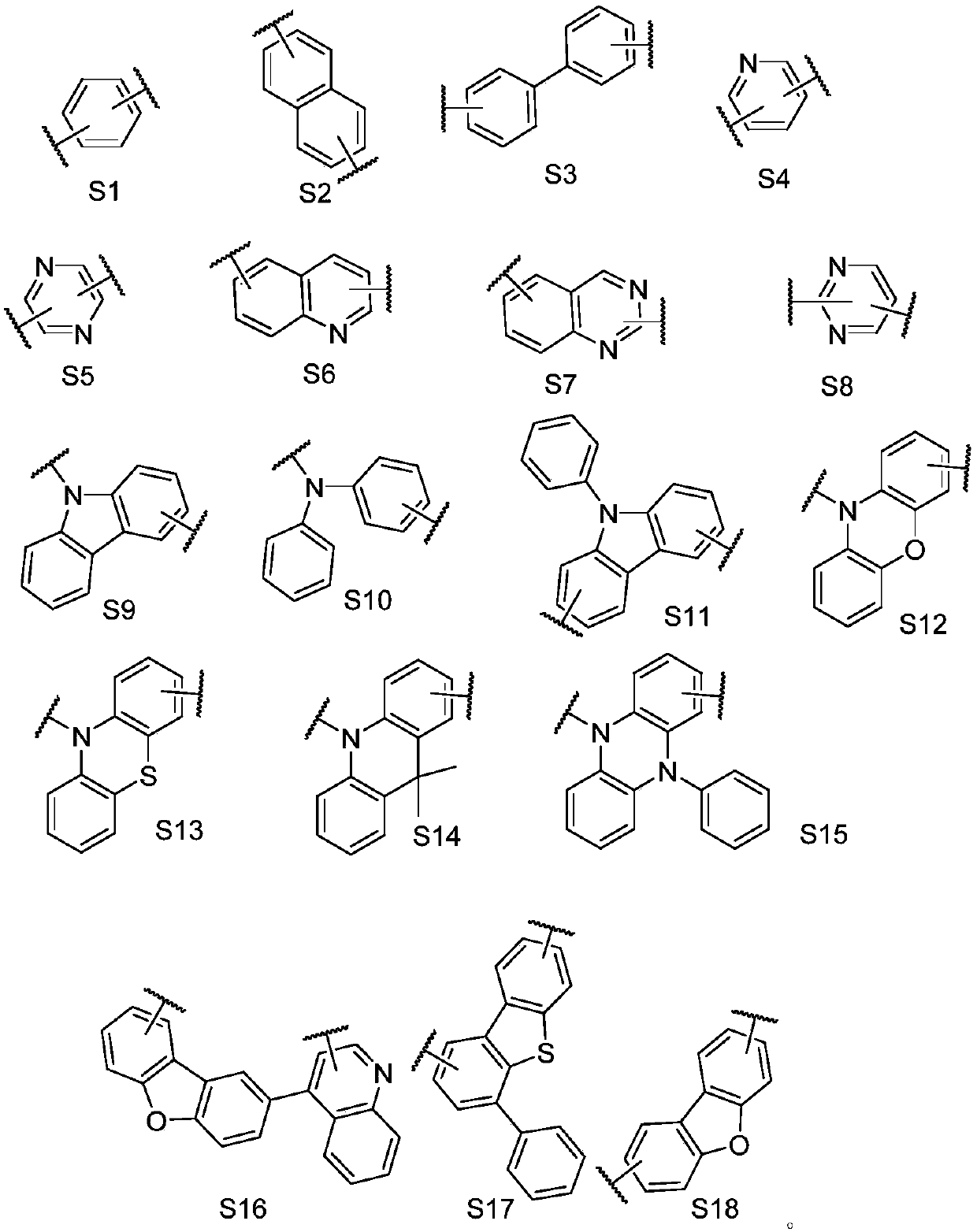

Anthraquinone organic electroluminescent material and application thereof

An organic layer, selected technology, applied in the direction of light-emitting materials, organic chemistry, circuits, etc., can solve the problems of light color deviation, unsuitable for display applications, and short life of blue PHOLEDs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] Preparation of intermediate M1:

[0062] In a 500mL three-necked flask, add 2-fluoro-4-bromobenzonitrile (10g, 50mmol), phenol (4.94g, 52.5mmol) and K 2 CO 3 (13.8g, 100mmol) and DMF (120mL), heated at 140°C for 4 hours under the protection of nitrogen. TLC monitored the reaction to completion. The reaction solution was cooled to room temperature, diluted with toluene (100mL), washed with water (50mL*2), separated to remove the water phase, and the organic phase was dried with anhydrous sodium sulfate and concentrated to a small volume. White solid, filtered to obtain intermediate M1 13.2g.

[0063] Preparation of intermediate M2:

[0064] Intermediate M1 (63g, 229mmol) was dissolved in EtOH (500mL), NaOH (27g, 689mmol) was added, heated to 100°C under nitrogen protection, and refluxed for 5h. TLC monitored until the reaction was complete. After cooling down, filter to obtain a solid. Adjust the system to PH=1 with hydrochloric acid (1N), extract the aqueous phas...

Embodiment approach

[0117] The organic light emitting diode includes a first electrode and a second electrode on the substrate, and an organic material between the electrodes, and a hole transport layer, a light-emitting layer, and an electron transport layer are included between the first electrode and the second electrode.

[0118] The substrate is the substrate used in organic light emitting displays, such as glass, polymer materials, and glass and polymer materials with TFT components.

[0119] The anode material can be indium tin oxide (ITO), indium zinc oxide (IZO), tin dioxide (SnO 2 ), zinc oxide (ZnO) and other transparent conductive materials, also metal materials such as silver and its alloys, aluminum and its alloys, organic conductive materials such as PEDOT, and multilayer structures of the above materials.

[0120] The device can also include a hole injection layer positioned between the hole transport layer and the anode, including but not limited to one or more combinations of HI...

Embodiment 1

[0143] The fabrication process of organic electroluminescent devices is as follows:

[0144] The glass plate coated with the ITO transparent conductive layer is ultrasonically treated in a commercial cleaning agent, rinsed in deionized water, ultrasonically degreased in acetone: ethanol mixed solvent, baked in a clean environment until the water is completely removed, and then cleaned with ultraviolet light. Light and ozone cleaning, and bombardment of the surface with a beam of low-energy cations;

[0145] Place the above-mentioned glass substrate with the anode in a vacuum chamber, and evacuate to 1×10 -5 ~9×10 -3 Pa, on the above-mentioned anode layer film vacuum evaporation HI-2 is used as the hole injection layer, the evaporation rate is 0.1nm / s, and the evaporation film thickness is 10nm;

[0146] Vacuum-deposit HT-2 on the hole injection layer as the hole transport layer of the device, the evaporation rate is 0.1nm / s, and the total film thickness is 40nm;

[0147] Va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com