Multi-block copolymer based on 2,5-furandicarboxylic acid polyester and aliphatic polycarbonate, and preparation method of multi-block copolymer

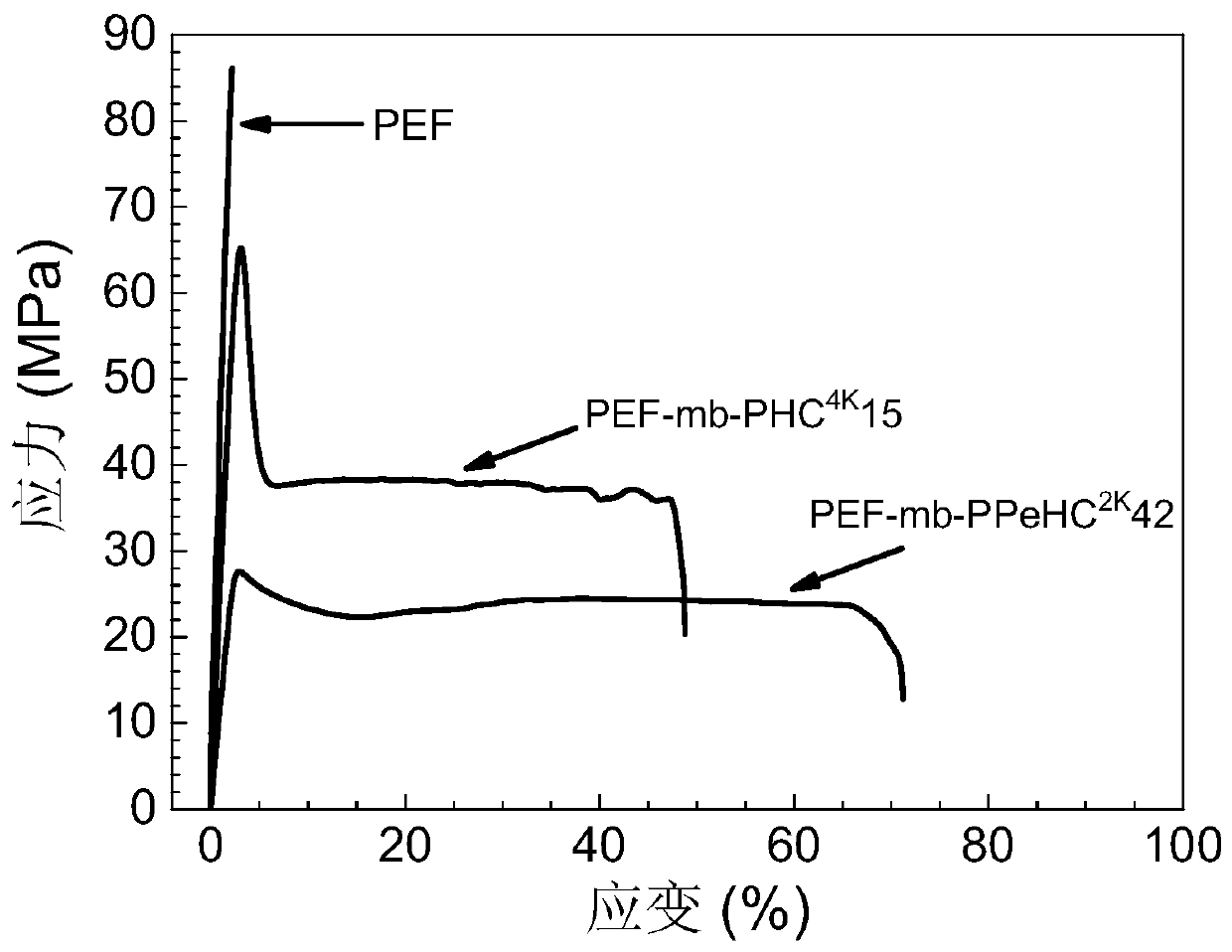

A technology of multi-block copolymer and furandicarboxylic acid, which is applied in the field of polymer materials, can solve the problems of limited improvement effect of impact toughness, poor gas barrier property, reduced gas barrier property, etc., and achieves high gas barrier property, low cost, The effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

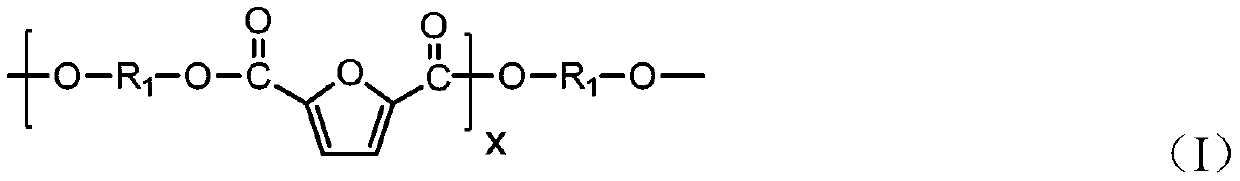

[0073](1) Add 70g dimethyl 2,5-furandicarboxylate, 50g ethylene glycol and 0.1g silicon dioxide / titanium dioxide composite to a reactor in a nitrogen atmosphere, react at 190°C for 1 hour, and react at 200°C for 4 hours to obtain Transesterification product; then add 0.08g antimony glycol and polycondense for 3 hours at 240°C under high vacuum (≦133Pa) to obtain prepolymer X.

[0074] (2) Add 8 g of hydroxyl-terminated polycarbonate 1,6-hexanediol ester and chain extender hexamethylene diisocyanate with a molecular weight of 4000 g / mol to the prepolymer X obtained in step (1) for chain extension For the reaction, the amount of the chain extender was 1.06 times the total molar amount of the prepolymer X and the hydroxyl-terminated poly(1,6-hexanediol carbonate) in the reaction system, and the final product was obtained after chain extension at 230° C. for 15 minutes.

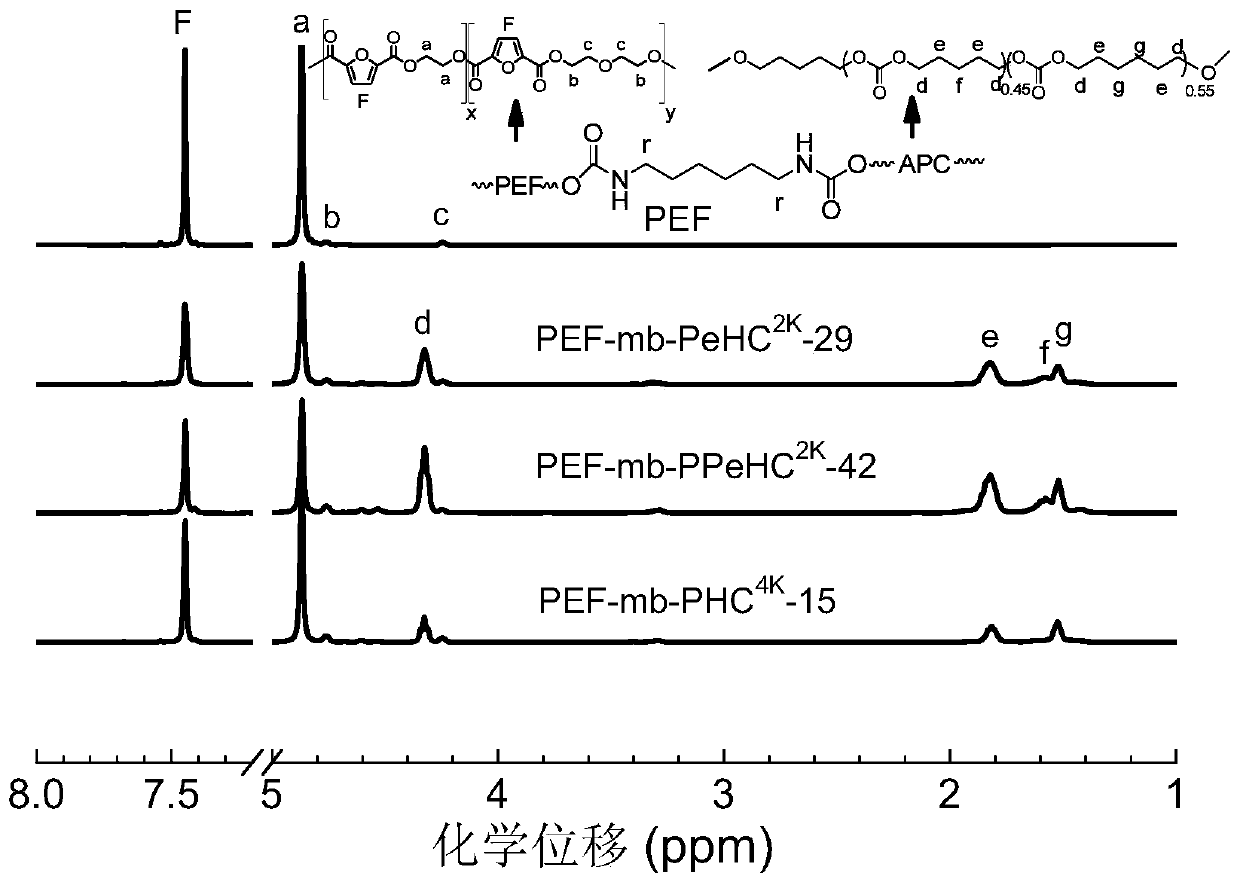

[0075] According to the H-NMR measurement, the soft segment of 1,6-hexanediol carbonate accounts for 10% of th...

Embodiment 2

[0077] (1) Add 70g dimethyl 2,5-furandicarboxylate, 50g ethylene glycol and 0.1g silicon dioxide / titanium dioxide composite to a reactor in a nitrogen atmosphere, react at 190°C for 1 hour, and react at 200°C for 4 hours to obtain Transesterification product; then add 0.08g antimony glycol and polycondense for 3 hours at 240°C under high vacuum (≦133Pa) to obtain prepolymer X.

[0078] (2) Add 13 g of hydroxyl-terminated polycarbonate 1,6-hexanediol and chain extender hexamethylene diisocyanate with a molecular weight of 4000 g / mol to the prepolymer X obtained in step (1) for chain extension For the reaction, the amount of the chain extender is 1.06 times the total molar amount of the prepolymer X and the hydroxyl-terminated poly(1,6-hexanediol carbonate) in the reaction system. After chain extension at 230° C. for 15 minutes, the final product was obtained.

[0079] According to the H-NMR measurement, the soft segment of 1,6-hexanediol carbonate accounts for 15% of the mass ...

Embodiment 3

[0081] (1) Add 70g dimethyl 2,5-furandicarboxylate, 60g ethylene glycol and 0.3g silicon dioxide / titanium dioxide composite to a reactor in a nitrogen atmosphere, react at 190°C for 1 hour, and react at 200°C for 4 hours to obtain transesterification product; then add 0.08g of antimony oxide and polycondense for 3 hours at 240°C under high vacuum (≦133Pa) to obtain prepolymer X.

[0082] (2) Add 24 g of hydroxyl-terminated polycarbonate 1,5-pentanediol-co-1,6-hexanediol ester with a molecular weight of 2000 g / mol to the prepolymer X obtained in step (1) (wherein Polycarbonate 1,5-pentanediol ester diol chain molar fraction is 45mol%) and chain extender hexamethylene diisocyanate to carry out chain extension reaction, the amount of chain extender is prepolymer X and hydroxyl in the reaction system 1.06 times the total molar weight of capped polycarbonate 1,5-pentanediol-co-1,6-hexanediol ester. After chain extension at 230° C. for 15 minutes, the final product was obtained.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com