High-stability wallpaper adhesive

A technology of wallpaper glue and glue base, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of low bonding stability, wallpaper glue is easy to be affected by moisture, etc., to achieve Stably maintain the bonding performance, guarantee the moisture-proof effect, and the effect that is not easy to be affected by moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

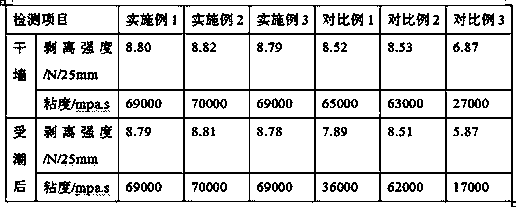

Examples

preparation example Construction

[0028] The preparation method of composite wallpaper glue base material, comprises the steps:

[0029](1) According to the mass ratio of 7:1~3:0.1:30~50, diatomite, hexacyclite passed through a 120 mesh sieve, silane coupling agent KH-550, and ethanol solution with a volume fraction of 70% were mixed and stirred, Immerse at room temperature for 8~12h, move to a centrifuge, centrifuge at 2000~4000r / min for 7~13min, collect the centrifuge and mix it with additives at a mass ratio of 5~8:2, heat mix at 75~83°C for 20~40min, cool down to 25~45℃, add Pingpingjia-O25 with 7~12% centrifuge mass, mix evenly, and homogenize at 3.1~5.2MPa for 7~13min to obtain a homogeneous material;

[0030] (2) In terms of parts by weight, take 25~40 parts of homogeneous material, 12~20 parts of fiber aggregate, 2~5 parts of rosin, 3~7 parts of hydrogenated rosin, and 70~90 parts of water in the reactor and mix them in 45 Stir at ~65°C for 40~60min, add catalyst with 1~4% of homogeneous material mass...

Embodiment 1

[0034] Catalyst: Mix stannous octoate and ferrocene at a mass ratio of 3:1 to obtain a catalyst.

[0035] Monomer liquid: in parts by weight, take 10 parts of acrylamide, 4 parts of methyl methacrylate, 1 part of disodium ethylenediamine tetraacetate, and 40 parts of sodium bicarbonate solution with a mass fraction of 20% and mix them to obtain mono body fluid.

[0036] Initiator: Mix potassium persulfide and sodium bisulfite at a mass ratio of 5:1 to obtain an initiator.

[0037] Fiber aggregate: at 75°C, mix microcrystalline cellulose and 1-allyl-3 methylimidazole chloride in a reaction kettle at a mass ratio of 1:20, protect with nitrogen, keep stirring for 4 hours to obtain a mixture, Raise the temperature to 120°C, take the mixed material and add stannous octoate, lactide, and p-dioxanone at a mass ratio of 10:1:1:6 to mix, keep the temperature for 5 hours, and cool naturally to room temperature to obtain the reaction material. The material is mixed with isopropanol at ...

Embodiment 2

[0047] Catalyst: Mix stannous octoate and ferrocene at a mass ratio of 5:1 to obtain a catalyst.

[0048] Monomer liquid: in parts by weight, take 12 parts of acrylamide, 6 parts of methyl methacrylate, 2 parts of disodium ethylenediamine tetraacetate, and 50 parts of sodium bicarbonate solution with a mass fraction of 20% and mix them to obtain mono body fluid.

[0049] Initiator: Mix potassium persulfide and sodium bisulfite at a mass ratio of 5:1.5 to obtain the initiator.

[0050] Fiber aggregate: at 80°C, mix microcrystalline cellulose and 1-allyl-3 methylimidazole chloride in a reaction kettle at a mass ratio of 1:25, protect with nitrogen, and keep stirring for 5 hours to obtain a mixture. Raise the temperature to 130°C, take the mixed material and add stannous octoate, lactide, and p-dioxanone at a mass ratio of 13:1:2:6 to mix, keep the temperature for 6 hours, and cool naturally to room temperature to obtain the reaction material. The material was mixed with isopro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com