Liquid slow release compound fertilizer and preparation method thereof

A compound fertilizer and slow-release technology, applied in the preparation of organic fertilizers, organic fertilizers, fertilizer mixtures, etc., can solve the problem of the water absorption rate of water-absorbing resins that are not disclosed, and achieve rich and easy-to-absorb nutrients, quality assurance, and excellent plant availability. The effect of direct absorption of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

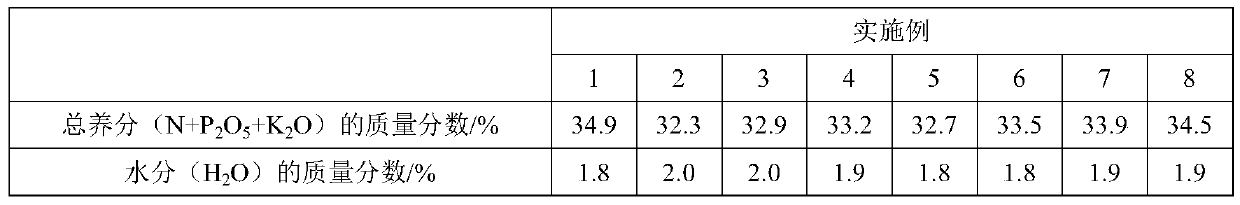

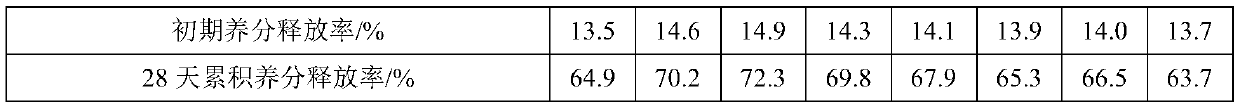

Examples

Embodiment 1

[0032] A liquid slow-release compound fertilizer prepared by the following steps:

[0033] (1) Weigh 30 parts of silica mud and 68 parts of fertilizer water and add them to the reaction kettle, stir at 100r / min, keep the system temperature at 70°C for 30 minutes, add 19.8 parts of amino acid solution to the reaction kettle, and control the reaction system The pH value is 6.5, and the reaction is continued for 2 hours while maintaining the above reaction conditions, and the product is cooled and filtered to obtain a silicon solution. The purpose of the amino acid solution is to complex trace elements while leaching the silicon in the silicon mud;

[0034] (2) Weigh 30 parts of urea, 16.7 parts of potassium dihydrogen phosphate, 39 parts of fertilizer water, 2.3 parts of boric acid and 1.2 parts of zinc sulfate and add them to the reaction kettle, the stirring speed is 120r / min, and the reaction is carried out under the condition of maintaining the system temperature at 40°C In ...

Embodiment 2

[0039] A liquid slow-release compound fertilizer prepared by the following steps:

[0040] (1) Weigh 30 parts of silica mud and 55 parts of fertilizer water and add them to the reactor, stir at 100r / min, maintain the system temperature at 70°C for 30 minutes, add 12 parts of amino acid solution to the reactor, and control the reaction system The pH value was 6.5, and the reaction was continued for 2 hours while maintaining the above reaction conditions, and the product was cooled and filtered to obtain a silicon solution;

[0041] (2) Weigh 30 parts of urea, 13 parts of potassium dihydrogen phosphate, 32 parts of fertilizer water, 1 part of boric acid and 1 part of zinc sulfate and add them to the reaction kettle, the stirring speed is 120r / min, and the reaction is carried out under the condition of maintaining the system temperature at 40°C In 21 minutes, 31 parts of amino acid solution were added to the reactor at an addition rate of 0.2 parts / min, and the reaction was conti...

Embodiment 3

[0046] A liquid slow-release compound fertilizer prepared by the following steps:

[0047] (1) Weigh 30 parts of silica mud and 80 parts of fertilizer water and add them to the reaction kettle, the stirring speed is 100r / min, keep the system temperature at 70°C for 30 minutes, add 40 parts of amino acid solution to the reaction kettle, and control the reaction system The pH value was 6.5, and the reaction was continued for 2 hours while maintaining the above reaction conditions, and the product was cooled and filtered to obtain a silicon solution;

[0048] (2) Weigh 30 parts of urea, 22 parts of potassium dihydrogen phosphate, 45 parts of fertilizer water, 5 parts of boric acid and 6 parts of zinc sulfate and add them to the reaction kettle, the stirring speed is 120r / min, and the reaction is performed under the condition of maintaining the system temperature at 40°C After 21 minutes, add 40 parts of amino acid solution to the reactor at an addition rate of 0.2 parts / min, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com