Method for extracting isoferulic acid from radix clematidis

A technology of isoferulic acid and extraction method, applied in the field of extraction, can solve the problems such as the decline of effective components ferulic acid and isoferulic acid, the increase of the cost of removing acid, the cumbersome extraction process, etc., to achieve true and reliable results, process safety, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] S1. Extraction method: crush Clematis clematis, pass through a 60-mesh sieve to obtain Clematis clematis powder, and pack it into a bag for later use; weigh 10 g of Clematis clematis powder and add 150 mL of ethyl acetate solution, heat and reflux at 60 ° C for extraction, and the extraction time is 120min, the number of extractions is 2 times, the 2 extracts are combined and filtered, the filtered extract is added to a rotary evaporator to concentrate under reduced pressure, the concentrated water temperature is 60 ° C, and the speed is 5 files to obtain the crude extract of isoferulic acid ;

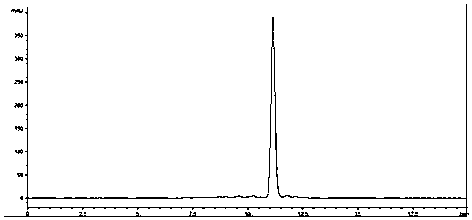

[0043] S2. Detection

[0044] (1) Dilute the isoferulic acid standard with the mobile phase to prepare the standard solution. The specific configuration steps are as follows:

[0045] Accurately weigh 20 mg of isoferulic acid standard substance, place it in a 25mL volumetric flask, dilute with mobile phase, shake well, and set the volume to the mark to obtain a standard solutio...

Embodiment 2

[0055] S1. Extraction method: crush Clematis clematis, pass through a 60-mesh sieve to obtain Clematis clematis powder, and pack it into a bag for later use; weigh 10 g of Clematis clematis powder and add 150 mL of ethyl acetate-acetic acid solution, heat and reflux at 60 ° C to extract, extract The time is 120min, the number of extractions is 2 times, the 2 extracts are combined and filtered, and the filtered extract is added to a rotary evaporator to concentrate under reduced pressure, the concentrated water temperature is 60°C, and the speed is 5 gears to obtain crude isoferulic acid. Extract;

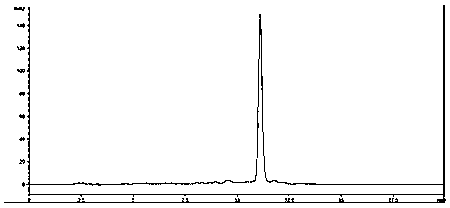

[0056] S2. Detection

[0057] The detection method is the same as in Example 1.

[0058] S3. Separation and purification: Weigh 2g of the extract obtained from S1, add 30ml of 40% methanol-water solution to dissolve, centrifuge at 4200r / min for 30min, take the supernatant, separate and purify by semi-preparative HPLC, and semi-preparative HPLC Chromatography is reversed-phase chro...

Embodiment 3

[0061] S1. Extraction method: crush Clematis clematis, pass through a 40-mesh sieve to obtain Clematis clematis powder, and pack it into a bag for later use; weigh 10 g of Clematis clematis leaf powder, add 100 mL of ethanol-formic acid aqueous solution, and extract under reflux at 80 ° C. The extraction time is 60min, the number of extractions is 2 times, the 2 extracts are combined and filtered, the filtered extract is added to a rotary evaporator to concentrate under reduced pressure, the concentrated water temperature is 60 ° C, and the speed is 5 files to obtain the crude extract of isoferulic acid ;

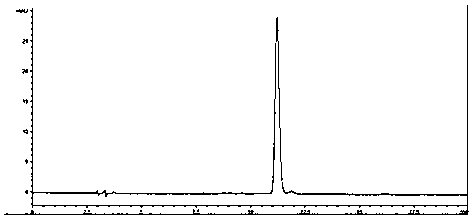

[0062] S2. Detection

[0063] The preparation method of standard solution and need testing solution is with embodiment 1;

[0064] The standard solution and the test solution were analyzed by HPLC respectively. HPLC chromatographic conditions: the chromatographic column is Venusil XBPC18; the mobile phase is acetonitrile-0.5% acetic acid aqueous solution (26:74, V / V); the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com