Composition, high-efficiency flame-retardant phase change thermal management composite material which is prepared from composition and preparation method of composition and high-efficiency flame-retardant phase change thermal management composite material

A phase change material and composite material technology, which is applied in the field of highly efficient flame retardant phase change thermal management composite material and its preparation, can solve the problems of low thermal conductivity, flame retardant performance test, secondary damage, etc., and achieve excellent mechanical properties, The flame retardant effect is obvious and the flame retardant efficiency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0136] In the third aspect, the present invention provides a method for preparing a high-efficiency flame-retardant phase-change thermal management composite material by using the composition, that is, a preparation method of a high-efficiency flame-retardant phase-change thermal management composite material, comprising the following steps:

[0137] (1) heating and melting the phase change material;

[0138] (2) Mix the melted phase-change material with the heat-conducting filler, and sieve after cooling;

[0139] (3) mixing the mixed material prepared in step (2) with flame retardant, resin-based material and antioxidant;

[0140] (4) Extrude and granulate the mixed material prepared in step (3) with glass fibers to obtain the high-efficiency flame-retardant phase-change thermal management composite material.

[0141] The composite material provided by the invention is a pellet, which can be used to prepare a high-efficiency flame-retardant phase-change thermal management c...

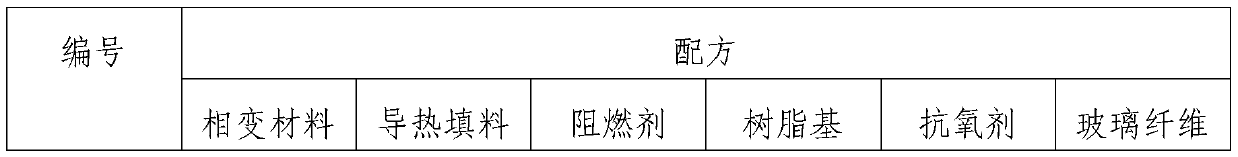

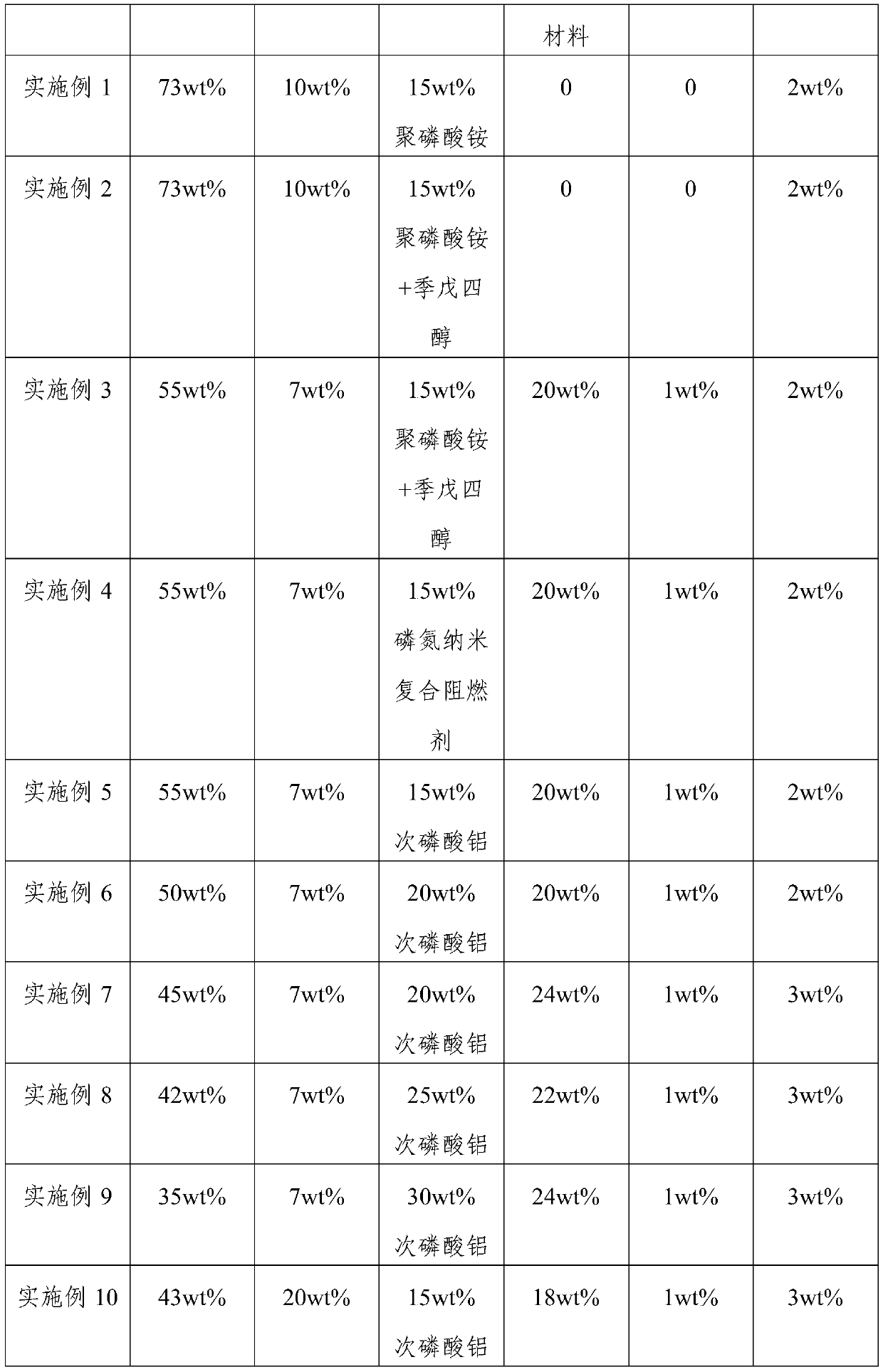

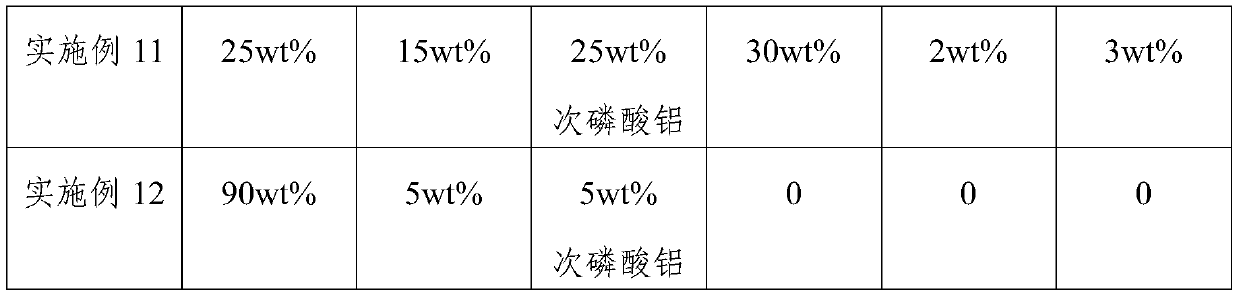

Embodiment 1

[0144] ① Weigh 7.3kg of paraffin phase change material with a phase transition temperature of 40°C, heat it in an oven at 70°C for 1 hour to melt it completely, then weigh 1.0kg of expanded graphite and add it to the vacuum heating stirring tank together with the melted paraffin Inside, stir for 30 minutes after vacuuming, sieve after cooling, then add 0.2kg of chopped glass fiber and 1.5kg of ammonium polyphosphate flame retardant, mix in a high-speed mixer for 20 minutes at high speed, fully stir until evenly mixed, Prepare high-efficiency flame-retardant phase-change material powder;

[0145] ②Put the uniformly mixed powder in step ① into the mold, and lay it evenly in the mold. After closing the mold, put it into the press and press the mold with a pressure of 20MPa. After holding the pressure for 30 minutes, remove the mold to obtain High-efficiency flame-retardant phase-change material components.

Embodiment 2

[0147]① Weigh 7.3kg of paraffin phase change material with a phase transition temperature of 40°C, heat it in an oven at 70°C for 1 hour to melt it completely, then weigh 1.0kg of expanded graphite and add it to the vacuum heating stirring tank together with the melted paraffin Inside, stir 30min after vacuumizing, sieve after it cools down, then add the ammonium polyphosphate of 0.2kg, the ammonium polyphosphate and pentaerythritol composite flame retardant of 0.2kg (wherein the mass ratio of ammonium polyphosphate and pentaerythritol is 3: 1) Mix in a high-speed mixer for 20 minutes at high speed, and stir until the mixture is evenly mixed to obtain a high-efficiency flame-retardant phase-change material powder;

[0148] ②Put the uniformly mixed powder in step ① into the mold, and lay it evenly in the mold. After closing the mold, put it into the press and press the mold with a pressure of 20MPa. After holding the pressure for 30 minutes, remove the mold to obtain High-effic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com