Supported cobalt-doped cerium dioxide nano-sheet preparation method

A ceria, supported technology, applied in the field of nanomaterials, can solve the problems of difficult two-dimensional flake nanostructure, inability to apply, poor conductivity, etc., and achieves the effect of clear structure, poor conductivity and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

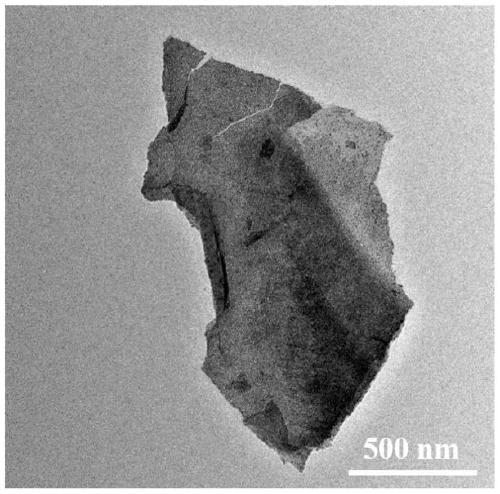

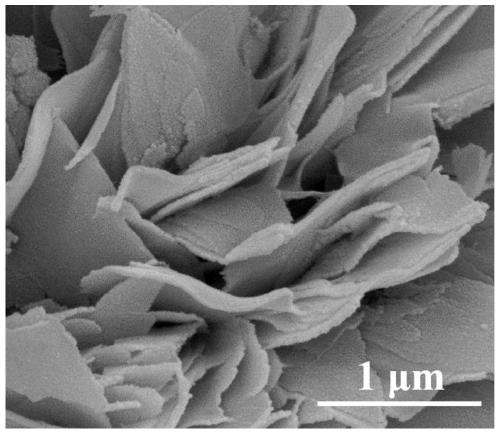

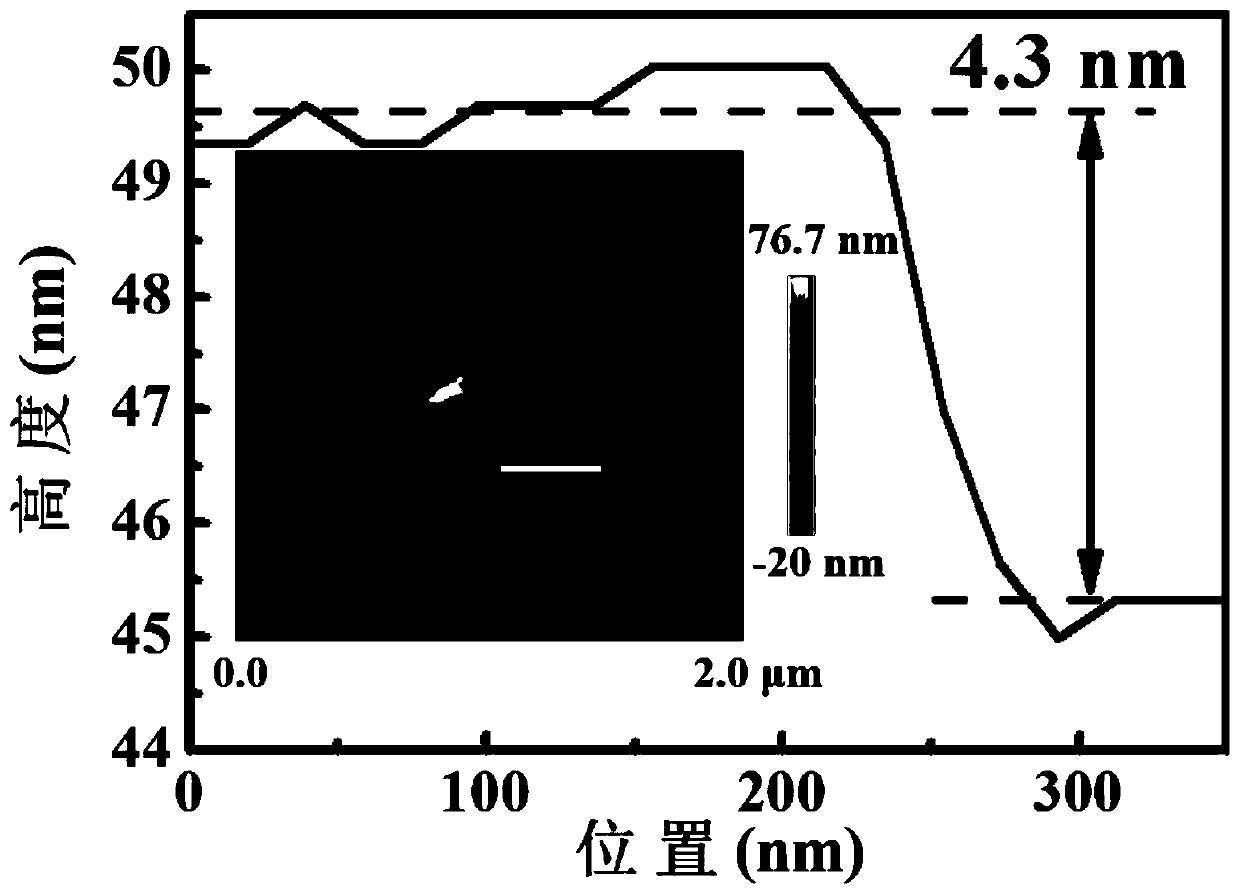

[0021] 0.5 mmol of cobalt acetate, 1.5 mmol and 125 mg of hexamethylenetetramine were dissolved in a mixed solution of ethanol (7 mL) and ethylene glycol (7.5 mL). The solution and copper foam carrier (2cm×3cm) were transferred to a 50mL hydrothermal kettle, and reacted in an oven at 170°C for 8h. The resulting product was washed with ethanol and air-dried naturally. The resulting precursor was calcined in a tube furnace at 400 °C for 2 h to obtain supported cobalt-doped ceria nanosheets (such as figure 2 ). The morphology of the material obtained by further removal is an ultrathin uniform nanosheet (such as figure 1 ), and its layer thickness is about 4nm (such as image 3 ). The electrocatalytic hydrogen evolution performance of the obtained supported cobalt-doped ceria nanosheets was tested in 1.0M potassium hydroxide solution, and the current density was 100mA cm -2 , the overpotential is 132mV (such as Figure 4 ).

Embodiment 2

[0023] 0.33 mmol of cobalt acetate, 1.67 mmol and 125 mg of hexamethylenetetramine were dissolved in a mixed solution of ethanol (7 mL) and ethylene glycol (7.5 mL). The solution and copper foam carrier (2cm×3cm) were transferred to a 50mL hydrothermal kettle, and reacted in an oven at 170°C for 8h. The resulting product was washed with ethanol and air-dried naturally. The obtained precursor was calcined in a tube furnace at 400° C. for 2 h to obtain supported cobalt-doped ceria nanosheets. The electrocatalytic hydrogen evolution performance of the obtained supported cobalt-doped ceria nanosheets was tested in 1.0M potassium hydroxide solution, and the current density was 100mA cm -2 , the overpotential is 134mV (such as Figure 4 ).

Embodiment 3

[0025] 1 mmol of cobalt acetate, 1 mmol and 125 mg of hexamethylenetetramine were dissolved in a mixed solution of ethanol (7 mL) and ethylene glycol (7.5 mL). The solution and copper foam carrier (2cm×3cm) were transferred to a 50mL hydrothermal kettle, and reacted in an oven at 170°C for 8h. The resulting product was washed with ethanol and air-dried naturally. The obtained precursor was calcined in a tube furnace at 400° C. for 2 h to obtain supported cobalt-doped ceria nanosheets. The electrocatalytic hydrogen evolution performance of the obtained supported cobalt-doped ceria nanosheets was tested in 1.0M potassium hydroxide solution, and the current density was 100mA cm -2 , the overpotential is 146mV (such as Figure 4 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com