Preparation method and application of perovskite-metal complex composite material

A technology of metal complexes and perovskite materials, applied in the direction of organic compound/hydride/coordination complex catalysts, non-metallic elements, chemical instruments and methods, etc., can solve the problems of poor catalytic activity and low separation efficiency of photogenerated charges problems, to achieve the effect of simple synthesis process and good material reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

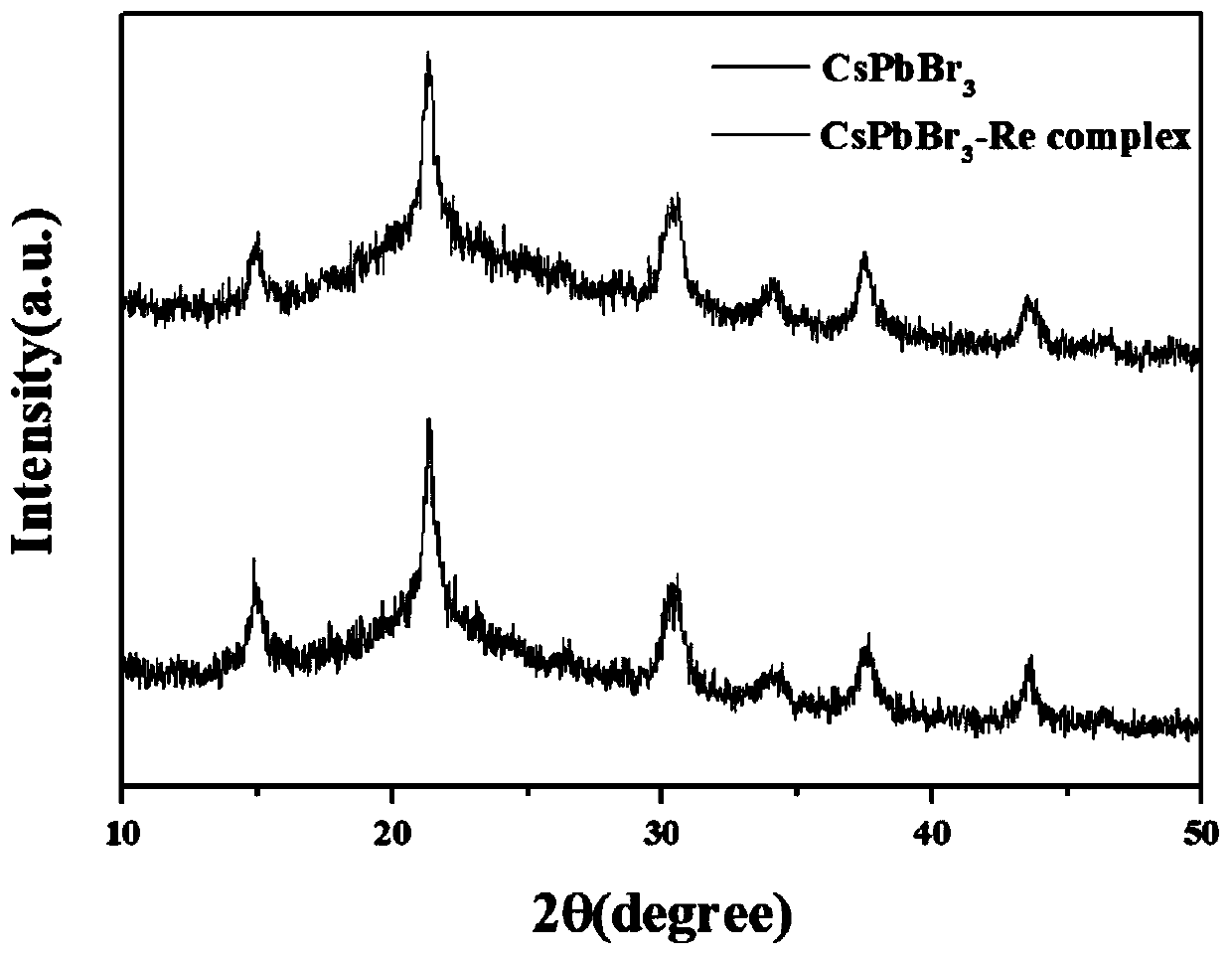

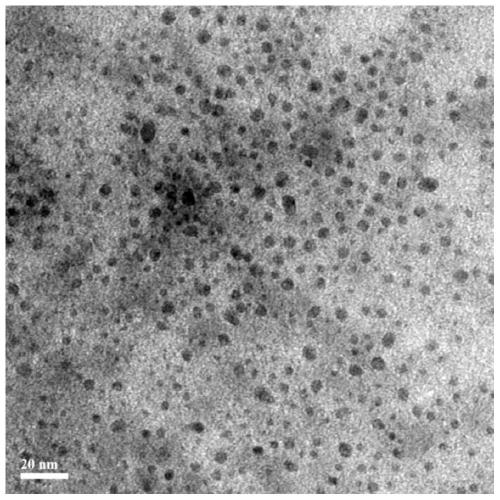

[0050] A preparation method of perovskite-metal complex composite material, comprising the following steps:

[0051] Step 1, 0.440g Cs 2 CO 3 Dissolve in 3mL propionic acid to obtain the precursor solution of cesium; 0.550g PbBr 2 Add to the mixed solution of 1mL isopropanol, 1mL propionic acid and 1mL butylamine to obtain the precursor solution of lead. Dilute 10 μL of the precursor solution of cesium propionate into a mixed solution of 1 mL of n-hexane and 0.5 mL of isopropanol, and quickly add 50 μL of PbBr under stirring 2 Precursor solution of bright yellow CsPbBr 3 Nanocrystal formation. Centrifuge at 8000rpm for 2min to separate the product, then wash with toluene;

[0052] Step 2, 0.2 g of Re(CO) 5 Br and 0.1 g of 4,4-dicarboxylic acid bipyridine (dcbpy) were dissolved in 15 mL of toluene solution, N 2 Reflux reaction at 115°C for 15 hours under atmosphere; the reaction was cooled to room temperature and centrifuged, then washed with dichloromethane and methanol...

Embodiment 2

[0056] A kind of perovskite-metal complex composite material CsPbBr 1.5 I 1.5 -Re(CO) 3 The preparation method of Br(dpbpy), comprises the following steps:

[0057] Step 1, 0.440g Cs 2 CO 3 Be dissolved in 3mL propionic acid to obtain the precursor solution of cesium; 0.2750g PbBr 2 and 0.3458 g PbI 2 Add to the mixed solution of 1mL isopropanol, 1mL propionic acid and 1mL butylamine to obtain the precursor solution of lead. Dilute 10 μL of the precursor solution of cesium propionate into a mixed solution of 1 mL of n-hexane and 0.5 mL of isopropanol, and quickly add 50 μL of PbI under stirring 2 precursor solution, with red CsPbBr 1.5 I 1.5 Nanocrystal formation. Centrifuge at 8000rpm for 2min to separate the product, then wash with ethyl acetate;

[0058] Step 2, 0.2 g of Re(CO) 5 Br and 0.1 g of 2,2'-bipyridine-4,4'-bisphosphoric acid were dissolved in 15 mL of toluene solution, N 2 Under atmosphere, 115°C was refluxed for 15h. After the reaction was cooled to ...

Embodiment 3

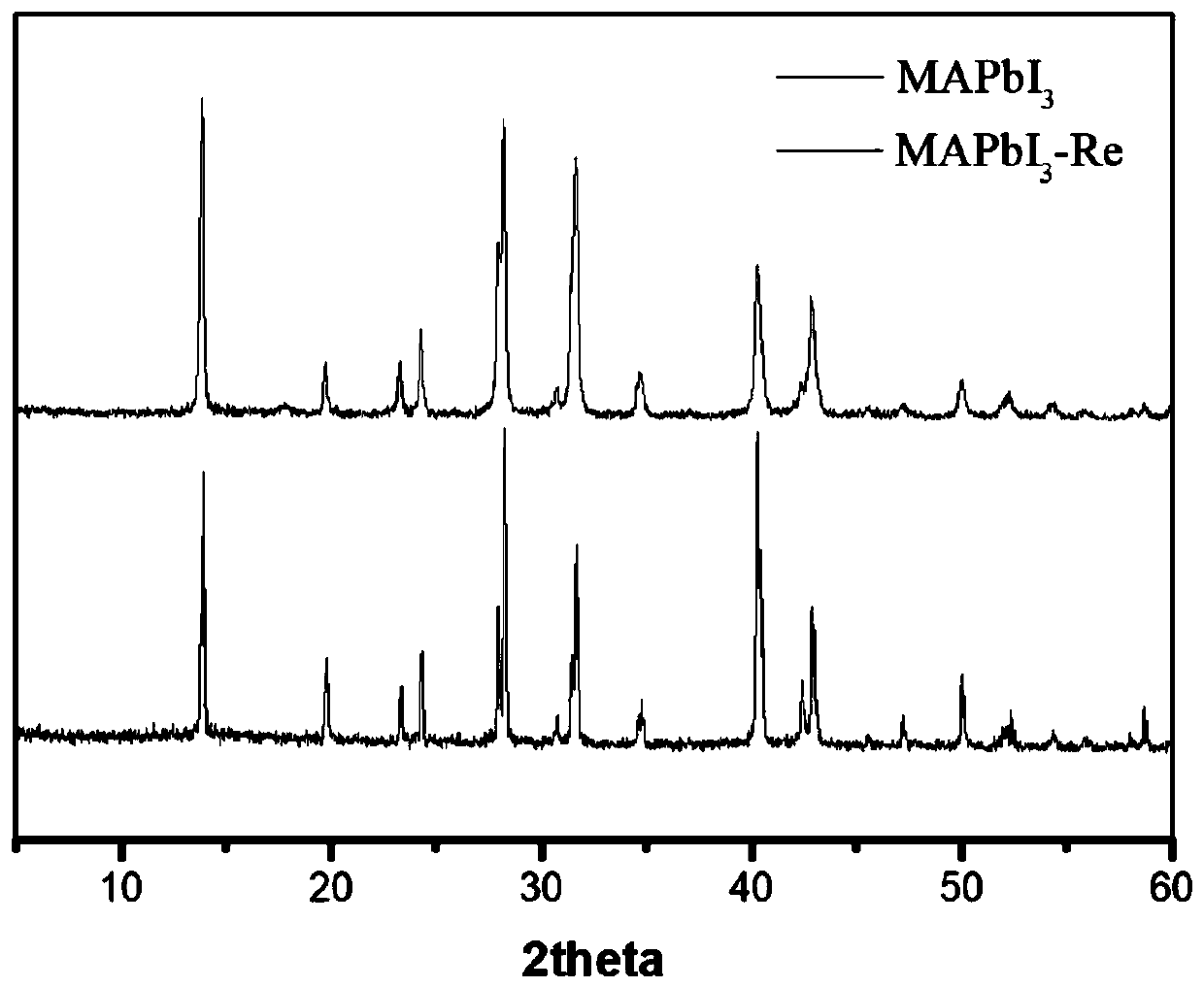

[0062] A perovskite-metal complex composite material MAPbI 3 -Re(CO) 3 The preparation method of Br(dcbpy), comprises the following steps:

[0063] 0.5gMAI, 1.5gPbI 2 Dissolve in 3 mL DMF, and add 300 μL oleic acid, 60 μL oleylamine to it, and add 3 mg of Re(CO) to the solution 3 The Br(dcbpy) complex powder was stirred at room temperature for 10 h; the solution formed above was S1, and S1 was added to chloroform according to the volume ratio of S1:poor solvent of 1:60, and the reaction solution was centrifuged to obtain the product.

[0064] attached image 3 For the MAPbI obtained in this embodiment 3 -Re(CO) 3 XRD pattern of Br(dcbpy) composite material, it can be seen that the composite material did not destroy MAPbI 3 Structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com