Mg-doped antimony sulfide-based thin-film solar cell and preparation method thereof

A technology of solar cells and antimony sulfide, which is applied in the field of materials, can solve the problems of battery efficiency decline, unsatisfactory performance of thin-film solar cells, and short-circuit current loss, etc., to improve battery performance, reduce surface defects, and reduce impurities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

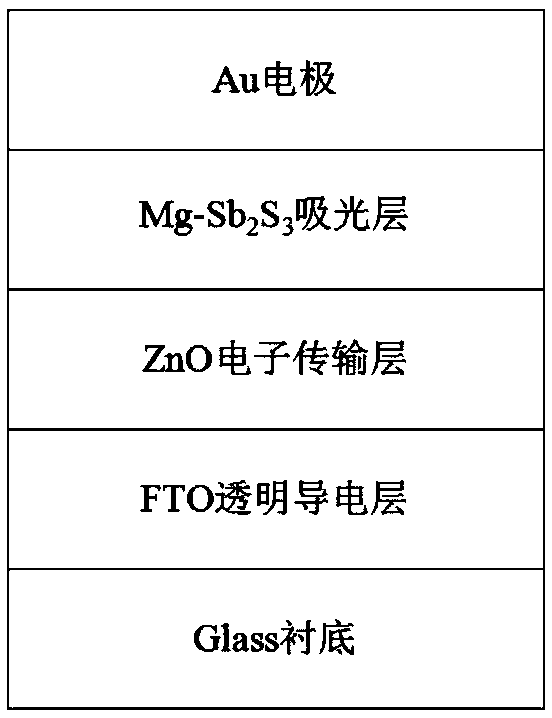

[0035] The present invention also provides a method for preparing a thin-film solar cell based on Mg-doped antimony sulfide, comprising the following steps:

[0036] (1) Clean the oxide transparent conductive substrate and dry it;

[0037] (2) Preparation of the electron transport layer: the ZnO precursor sol was prepared by the sol-gel method, and the ZnO precursor sol was evenly spin-coated on the transparent conductive substrate, and then calcined in a muffle furnace to obtain the electron transport layer;

[0038] (3) Preparation of light-absorbing layer: Sb containing Mg element 2 S 3 The precursor liquid is spin-coated on the electron transport layer, and then heated to cause the solution to react to form Mg-doped Sb 2 S 3 Thin films; repeated spin-coating and heating reaction steps to tune the resulting Mg-doped Sb 2 S 3 The thickness of the film; and then in an inert gas environment, the Mg doped Sb was annealed 2 S 3 The film is crystallized to obtain an inorga...

Embodiment 1

[0051] A kind of Mg-doped Sb based on the present invention 2 S 3 Prepared thin film solar cell, its preparation steps are as follows:

[0052] (1) Substrate treatment: Clean the FTO conductive glass sheet with appropriate shape and size repeatedly with cleaning agent and then rinse it with tap water; Ultrasonic cleaning for 15 minutes, and finally drying in an oven at 100°C, to obtain a FTO conductive glass substrate with a clean surface.

[0053] (2) Preparation of electron transport layer: Dissolve 0.4M zinc acetate and ethanolamine in ethylene glycol methyl ether according to 1:1, stir well until the yellow sol of ZnO precursor is obtained, and then spin-coat the ZnO precursor liquid on On the FTO glass substrate, the forward rotation speed (low rotation speed) is 500r / min for 15s, the rear rotation speed (high rotation speed) is 3000r / min for 30s, and then the sample is dried on a hot stage at 80°C for 5min. To ensure the thickness of the ZnO film, the above process wa...

Embodiment 2

[0057] A kind of Mg-doped Sb based on the present invention 2 S 3 Prepared thin film solar cell, its preparation steps are as follows:

[0058] (1) Substrate treatment: same as in Example 1;

[0059] (2) Preparation of electron transport layer: same as Example 1;

[0060] (3) Preparation of light-absorbing layer: first dissolve 1.14g antimony chloride in 20ml ethylene glycol methyl ether, and stir at room temperature for 30 minutes; then add 0.38g thiourea into the solution of antimony chloride in ethylene glycol methyl ether, and continue Stir at room temperature for 30 minutes until a light yellow sol is obtained; then add 0.2 g of thioacetamide to the above yellow sol, and continue stirring for 30 minutes; then follow the molar doping ratio of Mg (ie, Mg / (Mg+Sb) is 3% ) to which anhydrous MgCl was added 2 , and stirred for 30min to obtain a precursor solution containing Mg element; the Sb prepared according to the doping ratio (the molar ratio of Mg and Sb) of 3% 2 S ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com