Inorganic light element doped nickel-based material and preparation method and application thereof

A light element, inorganic nickel technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of nickel-based materials such as the gap in activity of platinum, and achieve the effects of alleviating the scarcity of precious metal resources, good hydrogen evolution activity, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

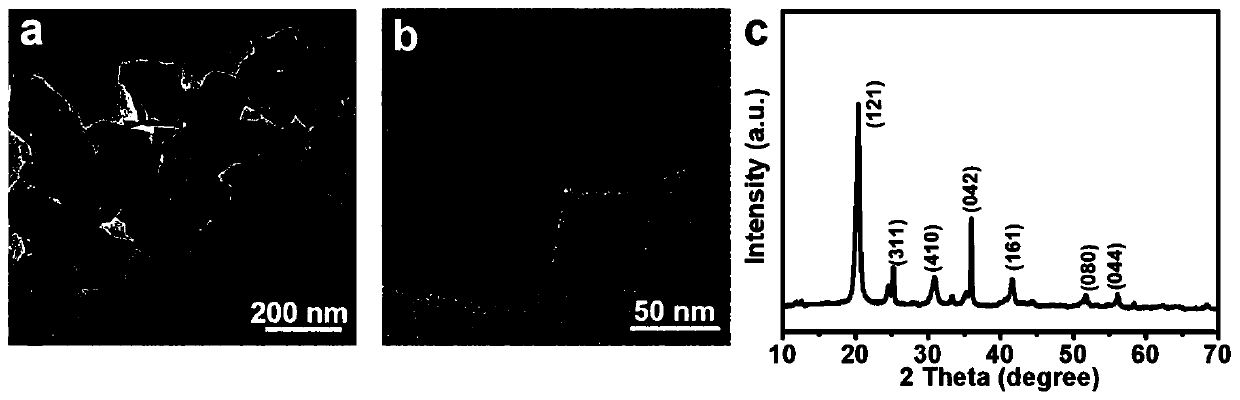

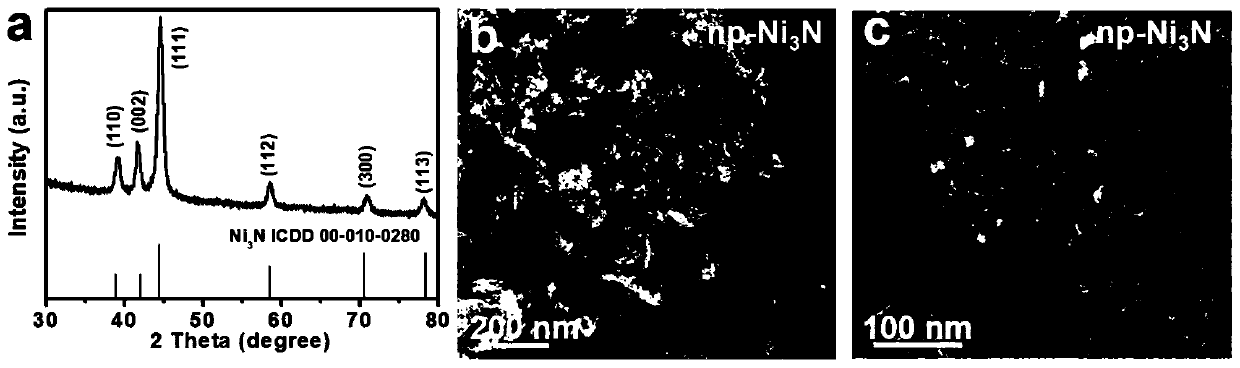

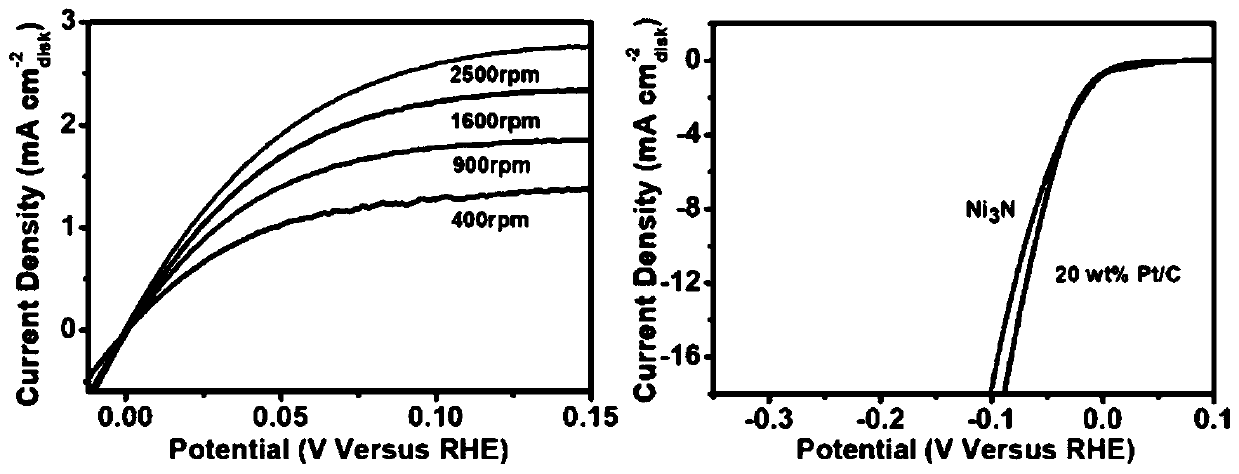

[0036] Example 1: Synthesis of nickel nitride with nickel coordination polymer as precursor

[0037] Dissolve 0.6mmol nickel nitrate hexahydrate and 0.3g polyvinylpyrrolidone in 20mL deionized water to obtain solution A, dissolve 0.4mmol nickel potassium cyanide in 20mL deionized water to obtain precipitant B, put solution A on a stirrer and stir vigorously for 5min , slowly drop into the precipitant B, after the dropwise addition, continue to stir for 2min, then stand at room temperature for aging for 24h, centrifuge, wash, and vacuum freeze-dry to obtain the nickel coordination polymer precursor, place the nickel coordination polymer in a vacuum tube Calcined in an ammonia atmosphere at 450°C for 1 h to prepare nickel nitride nanoparticles.

[0038] Depend on figure 1 It can be seen that the nickel coordination polymer is a square sheet with an irregular shape of 100-200 nm. Depend on figure 2 It can be seen that after high-temperature ammonification, the nickel squares ...

Embodiment 2

[0042] Example 2: Synthesis of carbon-doped nickel using Ni-MOF74 as a precursor

[0043] Weigh 0.043g 2,5-dihydroxyterephthalic acid, 0.13g nickel nitrate, 0.007g salicylic acid, and 45ml of reaction kettle, in 18ml of ethanol:N,N-dimethylformamide:water=1 : 1:1 solution ultrasonically dissolved completely. The reaction kettle was placed in an oven at 120°C for 8 hours, centrifuged, washed, and vacuum-dried to obtain the Ni-MOF74 precursor. Ni-MOF74 was placed in a vacuum tube furnace and calcined at 450 °C for 1 h in an argon atmosphere to prepare carbon-doped nickel nanomaterials.

Embodiment 3

[0044] Example 3: Using nickel hydroxide as a precursor to synthesize hydrogen-doped nickel

[0045] Dissolve 4mmol of nickel nitrate in 10ml of deionized water, add 5ml of ammonia water to obtain a soluble nickel-ammonia complex, quickly transfer the nickel-ammonia complex to 45ml of diethylene glycol, and put it in an oil bath at 100°C for 30min to make the ammonia gas Released to obtain a nickel hydroxide precursor. The nickel hydroxide precursor was calcined at 350°C for 1 h in a hydrogen atmosphere to prepare hydrogen-doped nickel hydride nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com