A long-acting repairing double-layer microcapsule

A microcapsule, double-layer technology, applied in the field of coatings, can solve the problems of microcapsule failure, weak microcapsule wall structure, unable to exert repairing effect, etc., and achieves the effect of maintaining activity, better and lasting repairing effect, and various repairing methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

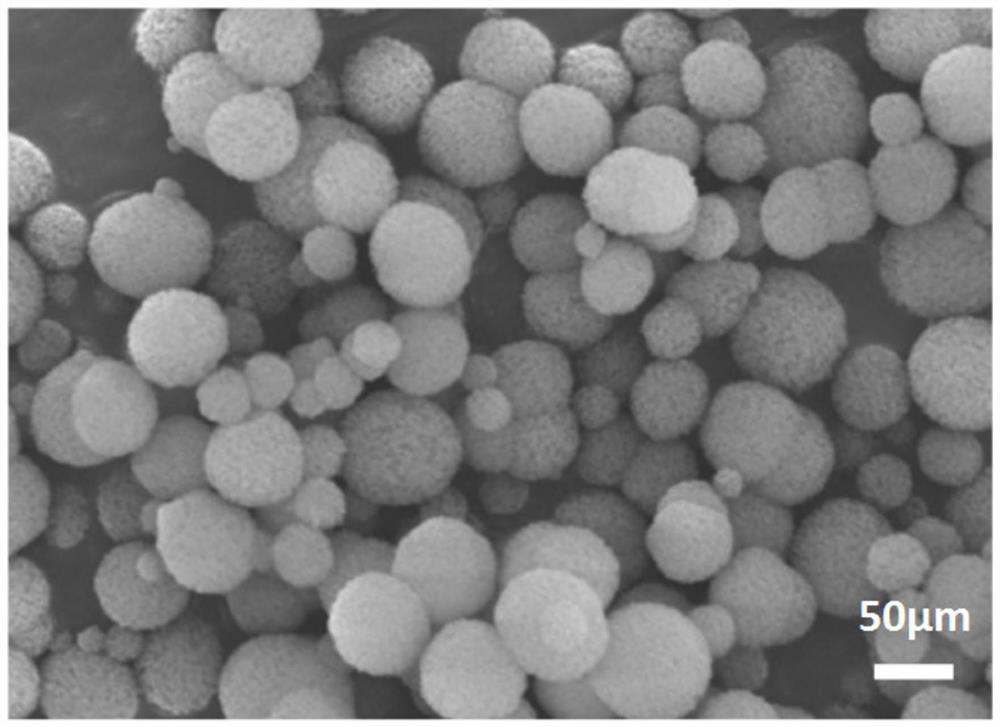

[0062] Preparation of long-acting double-layer microcapsules

[0063] (1) Preparation of styrene-divinylbenzene copolymer nanospheres

[0064] Take 0.0078g of azobisisobutyronitrile, add 1.4g of styrene, 2.1g of DVB (divinylbenzene (DVB, 80%, mixture of isomers, containing 4-tert-butylcatechol inhibitor at a concentration of less than 0.1%) and 4g sodium lauryl sulfate, stir and mix evenly to form an oil phase. Add 50mL of deionized water, mix evenly, and use a high-speed homogenizer to homogenize for 2min at a speed of 15000r / min to obtain a stable oil-in-water skin Kling emulsion. The resulting emulsion was added to a 100mL double-neck round bottom flask, cooled and replaced with nitrogen for 20min, and then the emulsion was heated in a water bath at 75°C for 16h. After the reaction, it was centrifuged at 6000r / min for 2min, and the product was collected and washed with 10mL of absolute ethanol Washing was carried out, and centrifugation was repeated 3 times. White solid st...

Embodiment 2

[0077] Preparation of long-acting double-layer microcapsules

[0078] (1) Preparation of styrene-divinylbenzene copolymer nanospheres

[0079] Take 0.0078g of azobisisobutyronitrile, add 1.5g of styrene, 2.2g of DVB (divinylbenzene (DVB, 80%, mixture of isomers, containing 4-tert-butylcatechol inhibitor at a concentration of less than 0.1%) ) and 4.3g of sodium lauryl sulfate, stir and mix evenly to form an oil phase. Add 50mL of deionized water, mix evenly, and use a high-speed homogenizer to homogenize at a speed of 12000r / min for 3min to obtain a stable water package Oily Pickering emulsion. The obtained emulsion was transferred to a 100mL double-neck round bottom flask, cooled and passed through nitrogen for 25min, then the emulsion was heated in a water bath at 73°C for 24h, and after the reaction, it was centrifuged at 6000r / min for 2min, and the product was collected and washed with 10mL of mixed alcohol ( (absolute ethanol:methanol=1:1 mixed alcohol) for washing, repe...

Embodiment 3

[0089] Preparation of long-acting double-layer microcapsules

[0090] (1) Preparation of styrene-divinylbenzene copolymer nanospheres

[0091] Take 0.008g of azobisisobutyronitrile, add 1.5g of styrene, 2.1g of DVB (divinylbenzene (DVB, 80%, mixture of isomers, containing 4-tert-butylcatechol inhibitor at a concentration of less than 0.1%) Mix with 4.1g sodium tetradecyl sulfate, stir and mix evenly to form an oil phase.Add 50mL of deionized water, mix evenly, and use a high-speed homogenizer to homogenize for 4min at a speed of 15000r / min to obtain a stable oil-in-water pg Lin emulsion. The obtained emulsion was put into a 100mL double-necked round bottom flask, and after cooling, the nitrogen was blown for 15min to replace the air, and then the emulsion was heated in a water bath at 79°C for 12h. After the reaction, it was centrifuged at 6000r / min for 2min, and the product was collected and dehydrated with 10mL of absolute ethanol. Washing, repeated centrifugal washing 3 ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com