A kind of high-activity heavy aromatics lightening catalyst and preparation method thereof

A technology for lightening and high activity of heavy aromatics, which can be used in catalyst activation/preparation, physical/chemical process catalysts, molecular sieve catalysts, etc. Stability, optimizing matching relationship, reducing the effect of carbon deposition inactivation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

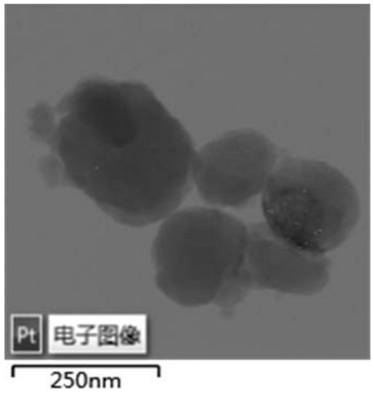

Image

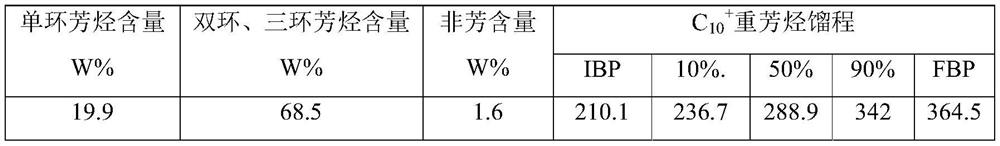

Examples

Embodiment 1

[0032] Example 1 Platinum (IV)-ammine complex solution

[0033] 1) Weigh 10.0g of platinum sponge, add 50ml of deionized water containing 5wt% hydrochloric acid, heat to boiling on an electric hot plate, keep for 30min in a slightly boiling state, and repeatedly wash three times with deionized water after filtration; add 160ml of aqua regia, Heat it on an electric hot plate in a slightly boiling state until the sponge platinum is completely dissolved, add concentrated hydrochloric acid with a total volume of 50 ml in three times to remove the remaining nitric acid and nitrogen compounds; add deionized water for several times to remove the remaining hydrochloric acid, until the pH test paper does not test for steam. Discoloration, it can be considered that the remaining hydrochloric acid has been driven out, and the solution is concentrated to 100 ml to obtain a chloroplatinic acid solution.

[0034] 2) Transfer the above chloroplatinic acid solution to a round-bottomed flask, ...

Embodiment 3

[0042] 1) Mix 80g Beta molecular sieve (dry basis) with 80g ZSM-5 molecular sieve (dry basis) and 40g pseudo-boehmite (dry basis) and 10g succulent powder, and add a mixture containing 9% acetic acid and 0.4% barium nitrate. 120g of solution, kneaded into mud after mixing, and extruded the product in an extruder as The strip catalyst was dried in air for 12 hours at room temperature, dried in air at 120°C for 8 hours, and calcined at 550°C for 6 hours in an air atmosphere to obtain a composite carrier.

[0043] 2) Add 10.0ml of platinum(IV)-ammine complex solution and 9.97g of solid ammonium citrate into 100ml of deionized water. After the solid is dissolved, place it in a water bath at 85°C for 1.5h at a constant temperature, and adjust the solution to 120ml An impregnation solution was prepared.

[0044] 3) The impregnation solution prepared in 2) was added dropwise to 200 g of the composite carrier at 30°C, immersed in an equal volume for 6 hours, and then placed in an ov...

Embodiment 4

[0046] 1) Mix 80g Beta molecular sieve (dry basis) with 80g ZSM-5 molecular sieve (dry basis) and 40g pseudo-boehmite (dry basis) and 10g succulent powder, and add a mixture containing 9% acetic acid and 0.4% barium nitrate. The solution was 120 g, the preparation conditions were the same as those in Example 1, and the composite carrier was prepared by calcining at 550° C. for 6 hours in an air atmosphere.

[0047] 2) Add 10.0ml of platinum(IV)-ammine complex solution and 9.97g of ammonium citrate solid into 100ml of deionized water. After the solid is dissolved, place it in a water bath at 85°C for 0.5h at a constant temperature, and make up the solution to 120ml An impregnation solution was prepared.

[0048] 3) The impregnation conditions were the same as in Example 1, and the finished catalyst CAT-2 was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com