Preparation method for phenolic aerogel

An aerogel and phenolic technology, applied in the field of preparation of phenolic aerogel, can solve the problems of unfavorable large-scale industrial production, long preparation period, expensive drying equipment and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

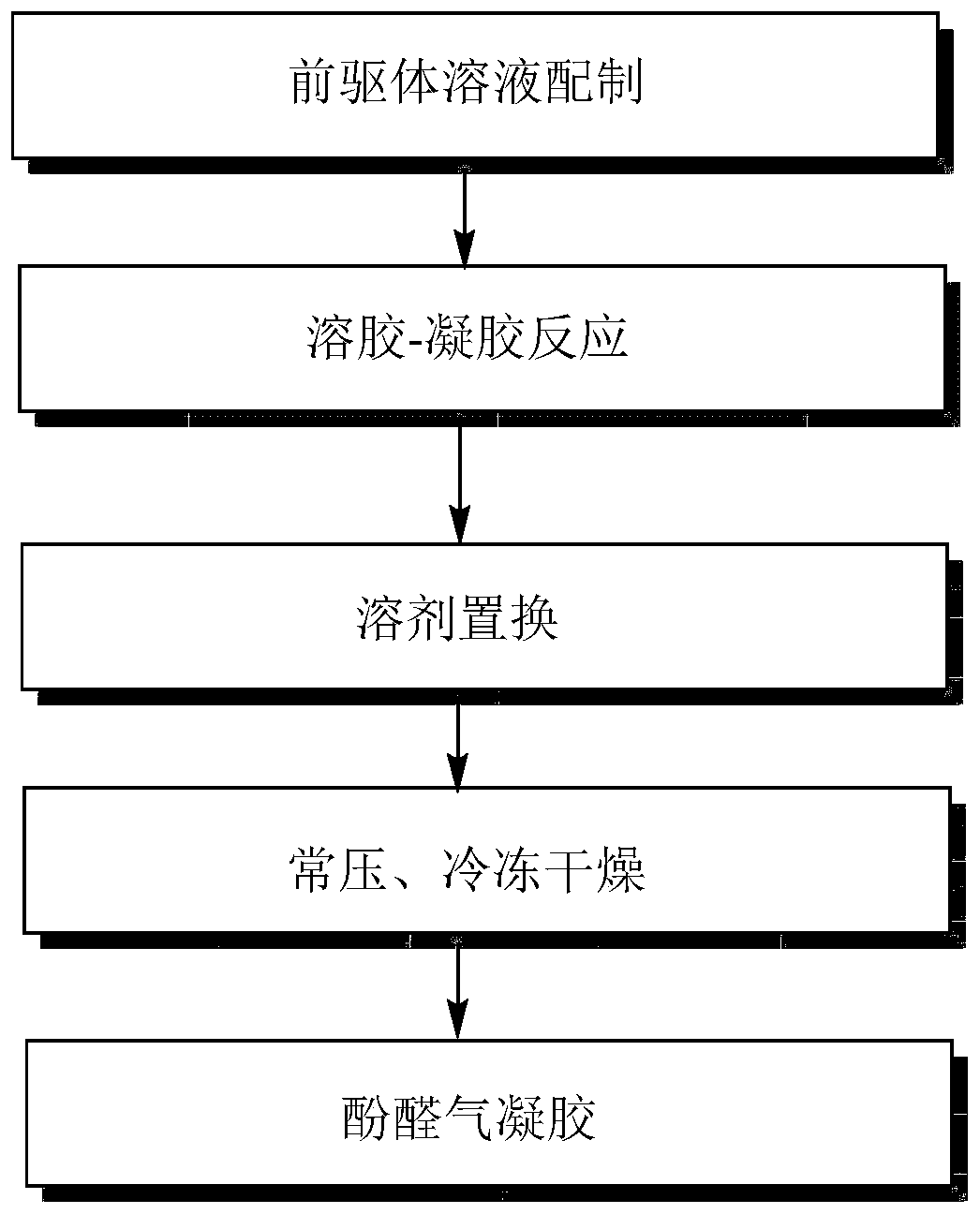

[0021] The invention provides a preparation method of the phenolic airgel with simple preparation process and low cost. The method is: a. Use phenols, aldehydes and amines as raw materials, add a basic catalyst, and add acid to adjust the pH value. b. Add accelerator, etherification agent, and water as solvent to adjust pH. c After the sol-gel reaction, the wet gel is obtained by curing, and the aqueous solution is replaced by an organic solvent, and dried to obtain the phenolic aerogel.

[0022] Described phenolic airgel can be prepared as follows:

[0023] Described aldehydes are any in liquid formaldehyde, paraformaldehyde, acetaldehyde, preferably liquid formaldehyde.

[0024] The basic catalyst is any one of NaOH, ethanolamine and diethanolamine.

[0025] The conditions for obtaining the mixture in step a: the reaction temperature is 55°C, the time is 0.5-1h; the molar ratio n 酚 :n 胺 :n 醛 =1:3:8.

[0026] The phenols are any one of phenol, resorcinol and phlorogluc...

Embodiment 1

[0034] The molar ratio of each component is n 苯酚 :n 三聚氰胺 :n 甲醛 =1:3:8, W (苯酚+三聚氰胺+甲醛) :W 水 =1:2

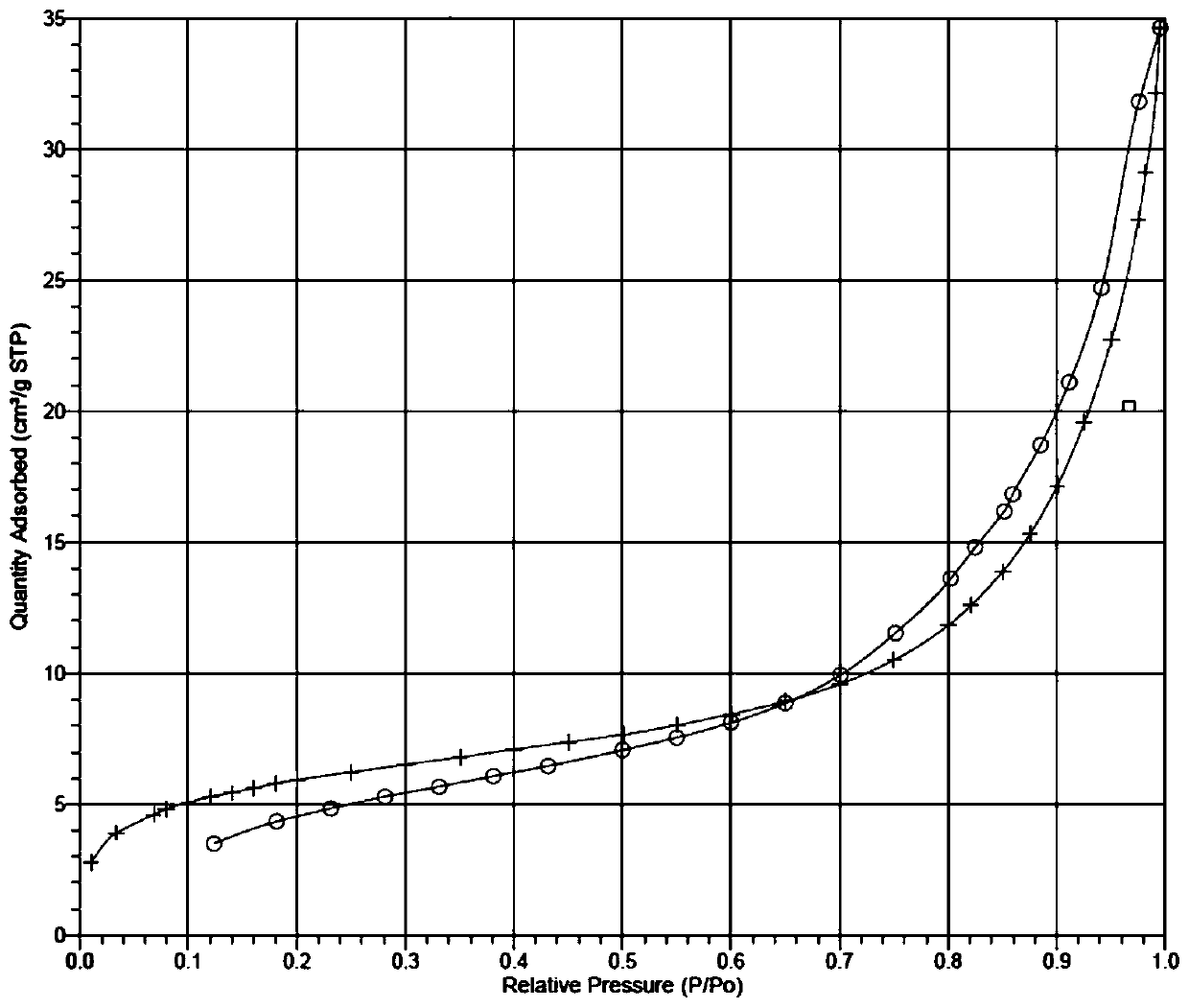

[0035] In a water bath at 55°C, add 68g of 37% liquid formaldehyde, 100g of distilled water, add 1g of triethanolamine, stir and mix, measure the pH and adjust the pH to 8.57 with 20% dilute hydrochloric acid (10g concentrated hydrochloric acid + 40g water). Then add 10g phenol and 40g melamine, react at 55°C, turn transparent and start to cool down to 50°C, stir steadily for 30min, cool down to 45°C, add 20% dilute hydrochloric acid dropwise to adjust to 7.75. Add 10g of methanol and 1g of ammonium persulfate, continue to react at 43-45°C for 30min, cool down to 30°C and discharge. At this time, the pH was adjusted to 1.04 with concentrated hydrochloric acid, and the solution was left to age for 3 days with the mouth closed, and the solution began to appear gelatinous. The obtained wet gel was soaked in tert-butanol to replace the water therein, and placed in a freeze dryer...

Embodiment 2

[0037] The molar ratio of each component is n 间苯二酚 :n 乙二胺 :n 甲醛 =1:3:8, W (间苯二酚+乙二胺+甲醛) :W 水 =1:2

[0038] In a water bath at 55°C, add 24g of paraformaldehyde, 104g of deionized water, 1g of diethanolamine, stir and mix, measure the pH, and adjust the pH to 8.50 with 20% dilute hydrochloric acid (10g of concentrated hydrochloric acid + 40g of water). Then add 10g of resorcinol and 18g of ethylenediamine and react at 55°C. After it becomes transparent, start to cool down to 50°C. Stir steadily for 30 minutes. Measure the pH after cooling down to 45°C. Add 20% dilute hydrochloric acid dropwise to adjust to 7.70. Add 10g of ethanol and 1g of potassium persulfate, continue to react at 43-45°C for 30min, cool down to 30°C and discharge. At this time, the pH was adjusted to 1.01 with concentrated hydrochloric acid, and the solution was left to age for 3 days with the mouth closed, and the solution began to appear gelatinous. The obtained wet gel was soaked in acetone to repla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com