Binder for sponge sand paper and preparation method thereof

A sponge sandpaper and binder technology, applied in the direction of polymer binder additives, non-polymer binder additives, novolak epoxy resin binders, etc., can solve the problem of substrates, abrasives and binders The problems of detachment, the easy aging of the adhesive, the short service life of the sponge sandpaper, etc., can enhance the heat resistance, strong adhesion, and improve the thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-3

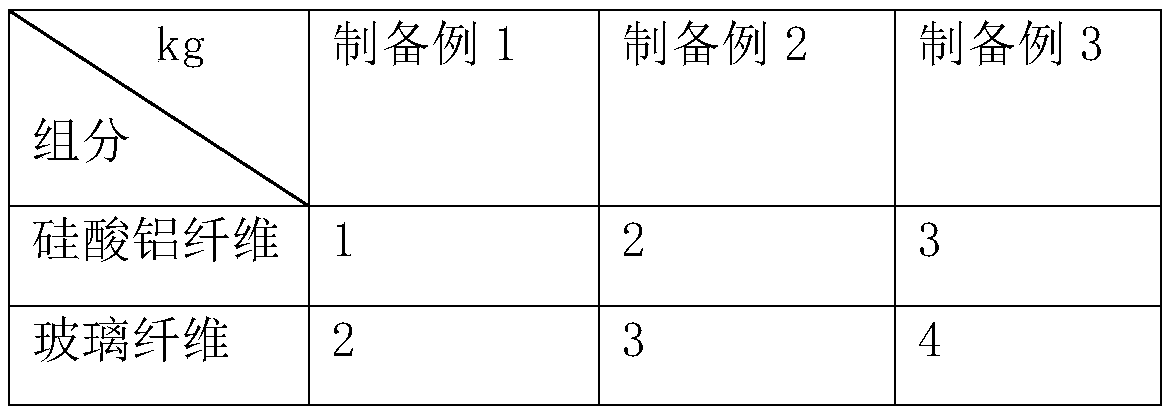

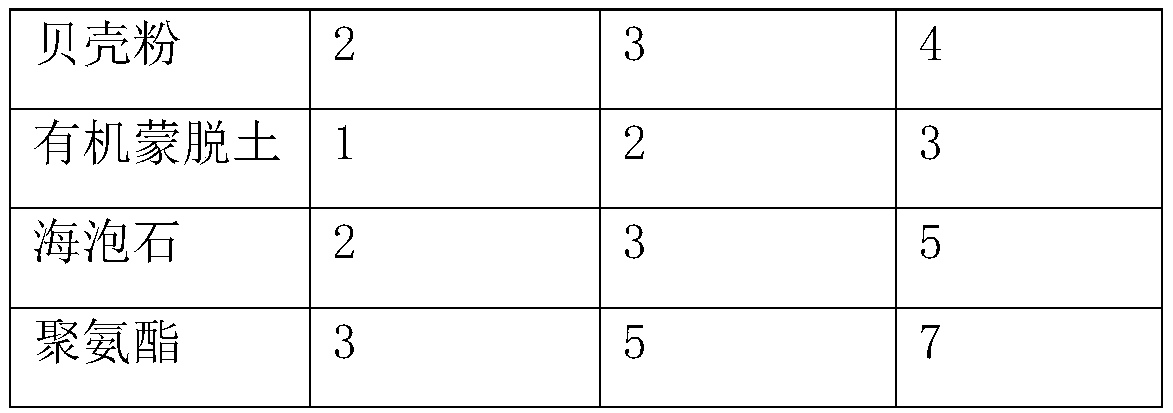

[0037] In Preparation Example 1-3, the aluminum silicate fiber is selected from the aluminum silicate fiber sold by Zibo Jinhe Thermal Insulation Material Co., Ltd. with the item number HP, and the glass fiber is selected from the glass with the item number 007 sold by Hejian Shilei Glass Fiber Cloth Factory. The fiber and shell powder are selected from the shell powder sold by Shijiazhuang Qun Teng Building Materials Sales Co., Ltd. with the item number B102, and the organic montmorillonite is selected from the organic montmorillonite and seafoam sold by the Lingshou County Ruixin Mineral Powder Factory with the item number 011 The stone was selected from the sepiolite sold by Lingshou County Zhongke Mineral Powder Co., Ltd. with the product number of 200, and the polyurethane was selected from the polyurethane sold by Daoqin Material Technology (Macheng) Co., Ltd. with the model number DAOQ.

preparation example 1

[0038]Preparation Example 1: (1) According to the proportioning in Table 1, 1kg of aluminum silicate fiber and 2kg of glass fiber were soaked in concentrated sulfuric acid solution for 1h, taken out, and dried. The mass ratio of aluminum silicate fiber to concentrated sulfuric acid was 1 :3;

[0039] (2) 2kg of shell powder, 1kg of organic montmorillonite and 2kg of sepiolite were added to acetone, ultrasonically treated for 30min, taken out, and dried. The mass ratio of shell powder to acetone was 1:5;

[0040] (3) Heat 3kg of polyurethane to 170°C, add the aluminum silicate fiber and glass fiber obtained in step (1), stir evenly, add the shell powder, organic montmorillonite and sepiolite obtained in step (2), and mix evenly Finally, it is dried and crushed into 10 μm powder to obtain a thermal insulation material.

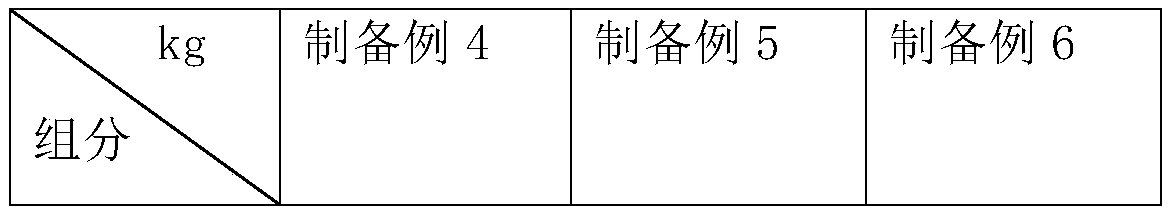

[0041] Table 1 Raw material ratio of heat insulating material in Preparation Example 1-3

[0042]

[0043]

preparation example 2

[0044] Preparation example 2: (1) soak 2kg of aluminum silicate fibers and 3kg of glass fibers in concentrated sulfuric acid solution for 1.5h, take them out, and dry them. The mass ratio of aluminum silicate fibers to concentrated sulfuric acid is 1:4;

[0045] (2) 3kg of shell powder, 2kg of organic montmorillonite and 3kg of sepiolite were added to acetone, ultrasonically treated for 35 minutes, taken out, and dried. The mass ratio of shell powder to acetone was 1:6;

[0046] (3) Heat 5kg of polyurethane to 180°C, add the aluminum silicate fiber and glass fiber obtained in step (1), stir evenly, add the shell powder, organic montmorillonite and sepiolite obtained in step (2), and mix evenly Finally, it is dried and crushed into 15 μm powder to obtain a thermal insulation material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com