Alfalfa silage agent and preparation method thereof

A technology of silage and alfalfa, applied in biochemical equipment and methods, microbe-based methods, bacteria used in food preparation, etc., can solve problems such as low content of lactic acid bacteria, inability to quickly ferment alfalfa sugar, failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

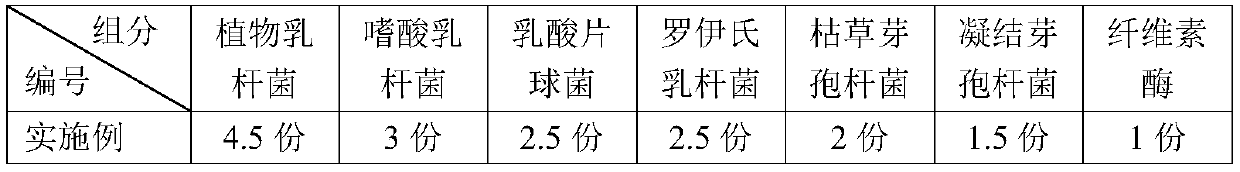

[0006] An alfalfa silage, comprising the following components in parts by mass: 4.5 parts of Lactobacillus plantarum, 3 parts of Lactobacillus acidophilus, 2.5 parts of Pediococcus acidilactici, 2.5 parts of Lactobacillus reuteri (Lactobacillus reuteri) 2.5 parts, Bacillus subtilis (Bacillus subtilis) 2 parts, Bacillus coagulans (Bacillus coagulans) 1.5 parts, cellulase 1 part.

[0007] The preparation method of above-mentioned alfalfa silage comprises the following steps:

[0008] Step 1, medium production:

[0009] Production of medium A: First, mix 4.5 parts of casein peptone, 4 parts of beef extract, 2 parts of yeast powder, 1 part of glucose, 1 part of sodium acetate, 2 parts of light calcium carbonate, 0.4 parts of ammonium citrate, and 0.2 parts of Tween 80 1 part, 0.1 part of potassium chloride, 0.1 part of magnesium sulfate, 0.1 part of manganese sulfate, 100 parts of distilled water, heated to 70°C, stirred to dissolve each raw material; Obtain sterilized A medium;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com