Supported aminoalkyl ionic liquid-metal catalyst, and preparation method and application thereof

A metal catalyst and ionic liquid technology, applied in the supported amine alkyl ionic liquid-metal catalyst and its preparation and application fields, can solve the problems of difficulty in improving hydrogenation activity, low selectivity, deamination and the like, and achieve improved selectivity , The preparation method is simple and the reaction conditions are mild.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

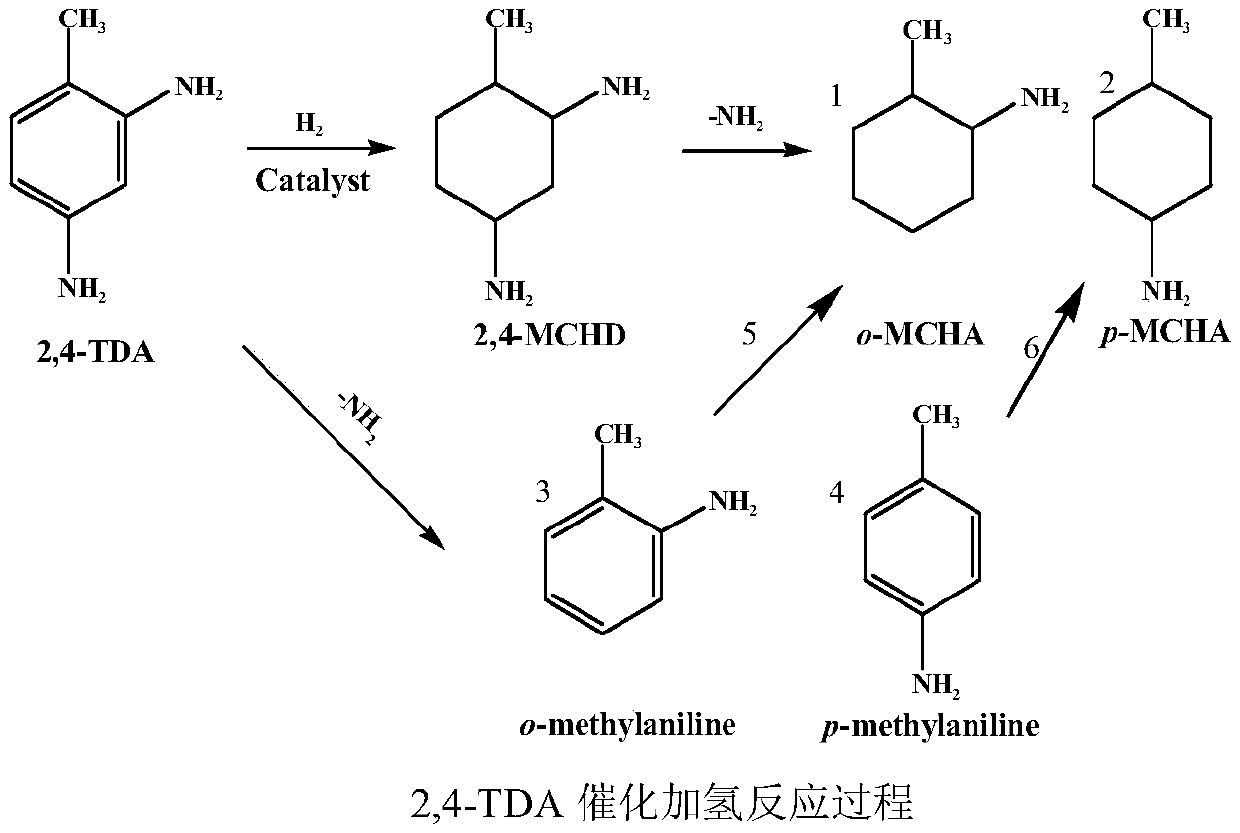

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Catalyst preparation:

[0056] Weigh 0.258g of ruthenium chloride trihydrate and 0.305g of potassium tetrachloropalladate in a three-necked flask, then add 14.1mL of deionized water into the flask, stir rapidly until completely dissolved; 2 / g, γ-Al with a bulk density of 0.85g / mL 2 o 3 Carrier 10g, stirred evenly, impregnated at room temperature for 12h; after impregnation, vacuum-dried at 110°C for about 10h; put the dried catalyst into a muffle furnace, and calcined at 400°C for 4h in an air atmosphere to obtain a calcined catalyst . Weigh 1g1-aminoethyl-3-methylimidazolium lysine salt ([C 2 NH 2 MIm][Lys]) ionic liquid and 14.1mL of deionized water were put into a three-necked flask and mixed evenly, then the roasted catalyst was added into the three-necked flask, stirred evenly, and immersed for 12h at room temperature; after the impregnation was completed, the catalyst was Vacuum drying at ℃ for about 10h; put the dried catalyst into a tube furnace, in a hydr...

Embodiment 2

[0060] Catalyst preparation:

[0061] Weigh 0.258g of ruthenium chloride trihydrate and 0.305g of potassium tetrachloropalladate in a three-necked flask, then add 14.1mL of deionized water into the flask, stir rapidly until completely dissolved; 2 / g, γ-Al with bulk density of 0.85 g / mL 2 o 3 Carrier 10g, stirred evenly, impregnated at room temperature for 12h; after impregnation, vacuum dried at 110°C for about 10h; put the dried catalyst into a muffle furnace, and calcined at 400°C for 4h in an air atmosphere to obtain a calcined catalyst . Weigh 1g 1-aminoethyl-3-methylimidazolium dicyanamide salt ([C 2 NH 2 MIm][N(CN) 2 ]) ionic liquid and 14.1mL of deionized water were put into a three-necked flask and mixed evenly, then the roasted catalyst was added into the three-necked flask, stirred evenly, and impregnated at room temperature for 12h; after impregnation, the catalyst was vacuum-dried at 110°C About 10h; put the dried catalyst into a tube furnace, and in a hydro...

Embodiment 3

[0065] Catalyst preparation:

[0066] Weigh 0.258g of ruthenium chloride trihydrate and 0.305g of potassium tetrachloropalladate in a three-necked flask, then add 14.1mL of deionized water into the flask, stir rapidly until completely dissolved; 2 / g, γ-Al with a bulk density of 0.85g / mL 2 o 3 Carrier 10g, stirred evenly, impregnated at room temperature for 12h; after impregnation, vacuum dried at 110°C for about 10h; put the dried catalyst into a muffle furnace, and calcined at 400°C for 4h in an air atmosphere to obtain a calcined catalyst . Weigh 1g 1-aminopropyl-3-methylimidazolium lysine salt ([C 3 NH 2 MIm][Lys]) ionic liquid and 14.1mL of deionized water were put into a three-necked flask and mixed evenly, then the roasted catalyst was added into the three-necked flask, stirred evenly, and immersed for 12h at room temperature; after the impregnation was completed, the catalyst was Vacuum drying at ℃ for about 10h; put the dried catalyst into a tube furnace, in a hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com