A kind of multifunctional calcium-silicon-based rare earth doped bioactive powder and its preparation method and application

A bioactive, rare-earth-doped technology, applied in a multifunctional calcium-silicon-based rare-earth-doped photothermal-fluorescence-field, can solve problems such as the inability to monitor the temperature of materials in deep tissues, and achieve great application potential and good fluorescence performance. , the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

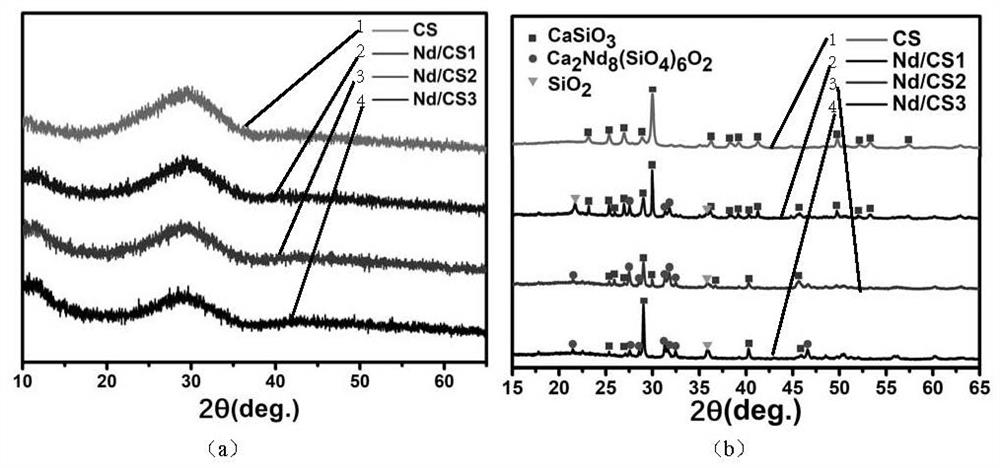

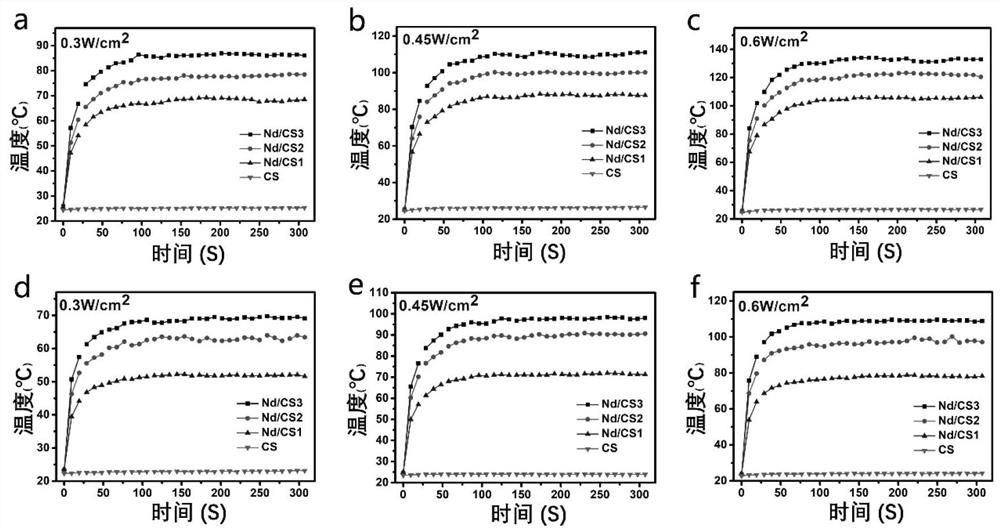

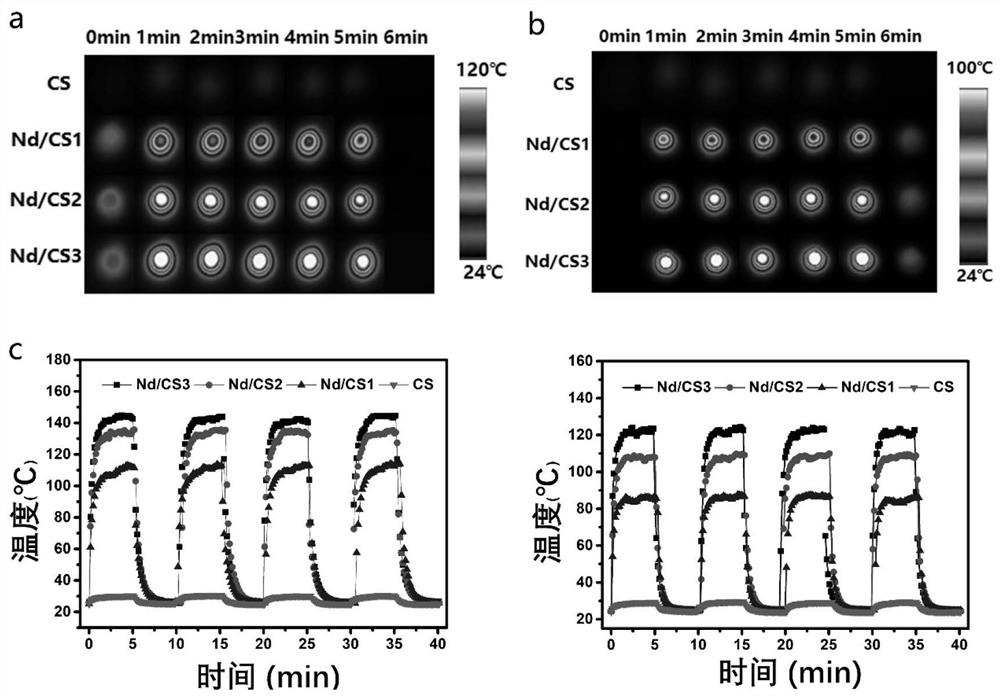

[0042] Preparation of bioactive glass powders. In one embodiment of the present invention, a container-less air suspension method is used to prepare multifunctional bioactive glass powder. Specifically, the bioactive powder prepared by co-precipitation is pressed into a ceramic tablet of a certain shape with a mold of a tablet machine (for example, a diameter of 6 mm). Then put the ceramic sheet into a containerless air suspension furnace, feed oxygen to suspend the ceramic sheet, and use carbon dioxide (CO 2 ) laser melting the obtained ceramic sheet to obtain a melt. Then cool at a speed of 300K / S (the cooling process is to disconnect the laser light source, and then the cooling process is mainly controlled by the cooling system), and finally form bioactive glass spheres. The biological activity is then rapidly heated to 400-600°C (eg, 500°C), removed, rapidly poured into deionized water, quenched, and then ground in an agate mortar. The obtained ground powder is further ...

Embodiment 1

[0051] (1) sodium silicate nonahydrate (Na 2 SiO 3 9H 2 O) solution was added dropwise to calcium nitrate tetrahydrate (Ca(NO 3 ) 2 4H 2 O) Dissolved in deionized water to obtain pure calcium silicate (CS) co-precipitated powder, magnetically stirred for 12 hours, then vacuum filtered, washed with deionized water and absolute ethanol for 3 times, and then placed in a 60°C oven for 48 Hour;

[0052] (2) Adopting a grinding tool with a diameter of 6mm to press the powder into a block, put it into an air suspension furnace to melt and cool it into a glass ball (the parameters of the container-free air suspension include: the throat diameter of the nozzle is 2mm; the laser power is 50W ; The holding time is 100 seconds; the gas used is oxygen, and the gas pressure is 0.8MPa). Then quickly heat up to 500°C, take it out and immediately pour it into deionized water to quench, put it into an agate mortar and grind it into powder, and pass it through a 200-mesh sieve to obtain mi...

Embodiment 2

[0056] (1) 56.84g sodium silicate nonahydrate (Na 2 SiO 3 9H 2 O) solution is added dropwise to 21.2535g calcium nitrate tetrahydrate (Ca(NO 3 ) 2 4H 2 O) and 4.3835g neodymium nitrate hexahydrate (Nd(NO 3 ) 3 ·6H 2 O) In the mixed solution, a multifunctional biomaterial (Nd / CS1) with a neodymium doping content of 1.9 at% of Ca:Nd=9:1 was obtained. Stir magnetically for 12 hours, then vacuum filter, then wash with deionized water and absolute ethanol for 3 times, and then place in an oven at 60°C for 48 hours;

[0057] (2) Adopting a grinding tool with a diameter of 6mm to press the powder into a block, put it into an air suspension furnace to melt and cool it into a glass ball (the parameters of the container-free air suspension include: the throat diameter of the nozzle is 2mm; the laser power is 50W ; The holding time is 100 seconds; the gas used is oxygen, and the gas pressure is 0.8MPa). Then quickly heat up to 500°C, take it out and immediately pour it into deio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com