Preparation technology of soluble starch

A preparation process and soluble technology, applied in the field of soluble starch preparation technology, can solve the problems of different starch hydrolysis conditions, poor homogeneity of soluble starch, etc., and achieve the effects of low labor cost, long hydrolysis reaction time, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

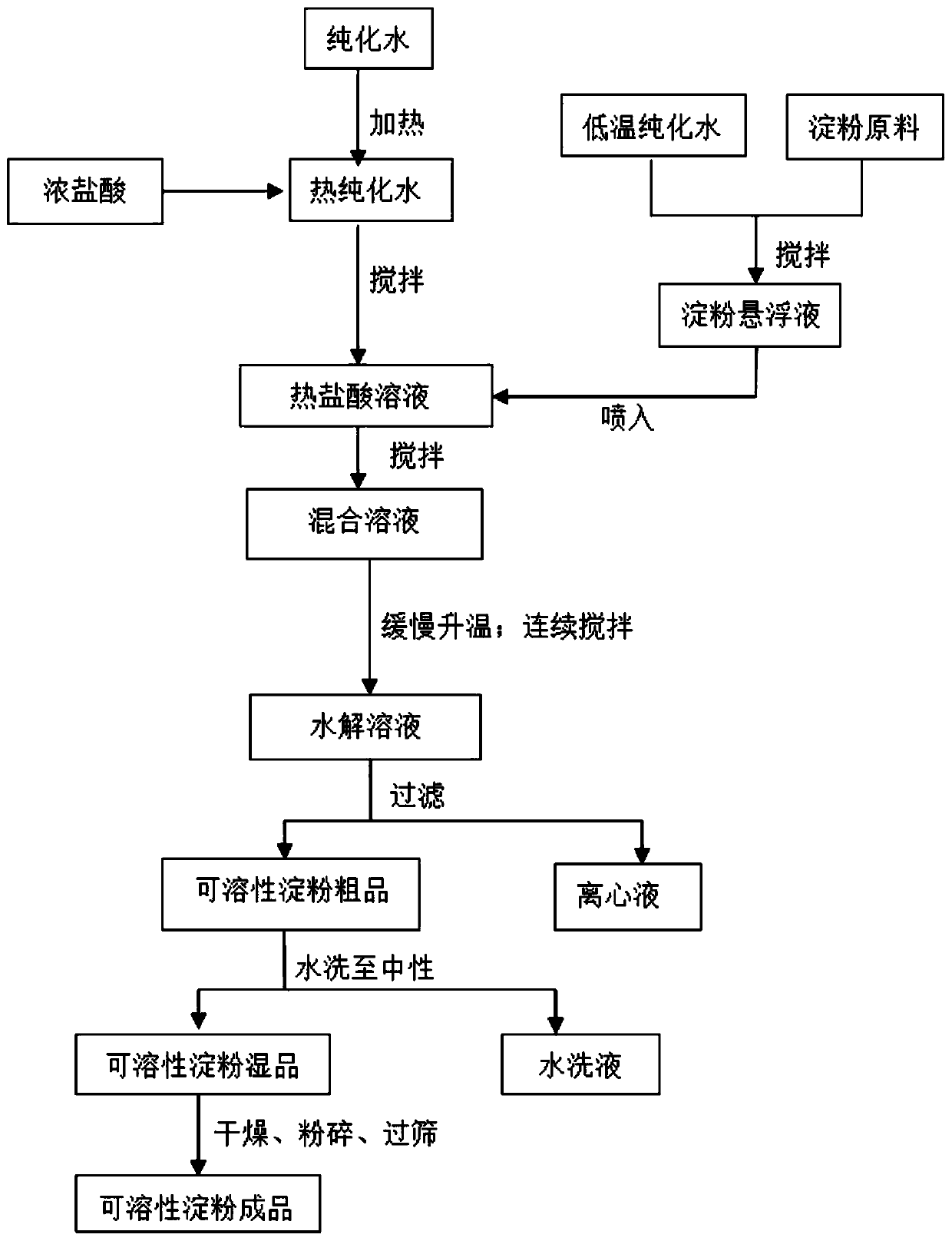

[0035] Please refer to figure 1 as shown, figure 1 The process flow chart prepared for soluble starch of the present invention comprises the following steps:

[0036] Step 1: Preparation of raw and auxiliary materials: heat purified water twice the mass of the starch raw material to 30-40°C, add concentrated hydrochloric acid solution 6.0-10.5% of the mass of the starch raw material, stir to make a hot hydrochloric acid solution, and set aside; the starch raw material Add 5-20°C low-temperature purified water of 1 times the mass of the starch raw material, stir to make a starch suspension, and set aside;

[0037] Step 2: Spray the starch suspension into the hot hydrochloric acid solution in the form of mist, and stir to form a mixed solution;

[0038] Step 3: Stir the mixed solution continuously, gradually and slowly heat the mixed solution to 45-65° C., and perform a hydrolysis reaction at the above-mentioned 45-65° C. for 7-24 hours to obtain a hydrolysis solution;

[003...

Embodiment 2

[0049] The optimization of the key technical parameters for the preparation of soluble starch in Example 1 is specifically described below through specific tests. In the preparation process of soluble starch, the polymer of soluble starch product is used as the reference standard, and the solubility of soluble starch and the sensitivity test to iodine are optimized.

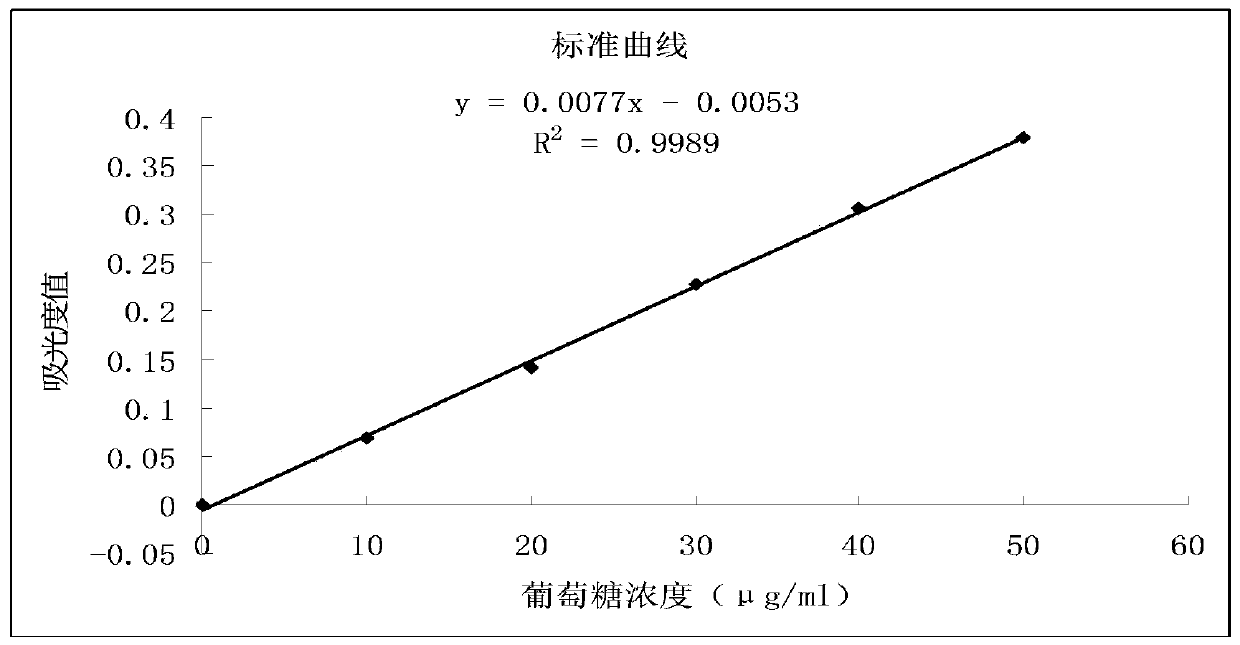

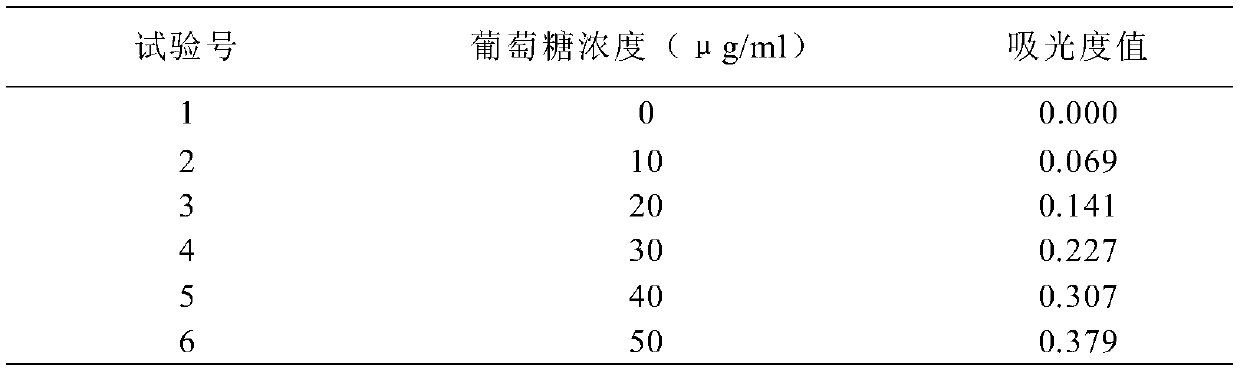

[0050] The testing method for the degree of polymerization of soluble starch is: Somogyi colorimetric method, the principle of which is: soluble starch has exposed reducing ends, which can show certain reducing properties. In an alkaline environment, complexed Cu 2+ Can oxidize soluble starch to the corresponding acid, Cu 2+ is reduced to Cu + , form cuprous oxide precipitation; cuprous oxide can react with arsenomolybdic acid reagent to generate blue substance, the depth of its color is proportional to the concentration of reducing sugar, and has the maximum absorption at 560nm, the content of reducing sugar c...

Embodiment 3

[0107] Now in combination with the contents of Example 1 and Example 2, 3 batches (9 groups in total) of soluble starch were prepared. The starch raw materials produced by the 4 groups of pilot plants were corn starch, sweet potato starch, potato starch and kudzu root starch purchased from Xi'an Guowei Starch Co., Ltd. for testing. The equipment used in production includes: CT-C-II hot air circulation oven, SXG-5 rotary flash dryer, Kx1000 stainless steel rotary vibrating screen, GFSJ-32 high-efficiency pulverizer, improved 2000L with spray function The enamel reaction kettle, atomizing nozzle, centrifuge, several mixing tanks, reaction tank with interlayer, etc.

[0108] 1. One batch of pilot production, including 3 groups of parallel tests, 1 to 3 groups:

[0109] Step 1: Preparation of raw and auxiliary materials: add 200kg of cornstarch to 200L of 5-20°C low-temperature purified water in 1# mixing tank, stir to make cornstarch suspension, and set aside; add 400L of cornst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com