Method for optimizing ultrasonic-assisted extraction of tuber salep polysaccharide based on response surface methodology

A technology of ultrasonic-assisted extraction and response surface methodology, which is applied in the fields of polysaccharide/gum-containing food ingredients, applications, pharmaceutical formulations, etc., can solve the problems of reduced activity, loss of thermally unstable components, difficult industrial production, etc., and achieves polysaccharide yield. High, reduced extraction time, high antioxidant activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 (response surface method)

[0024] a. Use a pulverizer to pulverize the dry products of Zhongyabai and tubers, pass through a 40-mesh sieve, and store in a ziplock bag at a temperature of 4°C;

[0025] b. Degrease the medium white and coarse powder obtained in step a with petroleum ether Soxhlet reflux for 20 hours at a temperature of 60° C., filter with suction, and evaporate the solvent from the filter residue under flowing air;

[0026] c. Soxhlet reflux with ethanol for 20 hours to remove the pigment and small molecules obtained in step b, and remove the pigment and small molecules, and filter the filter residue under flowing air to volatilize the solvent;

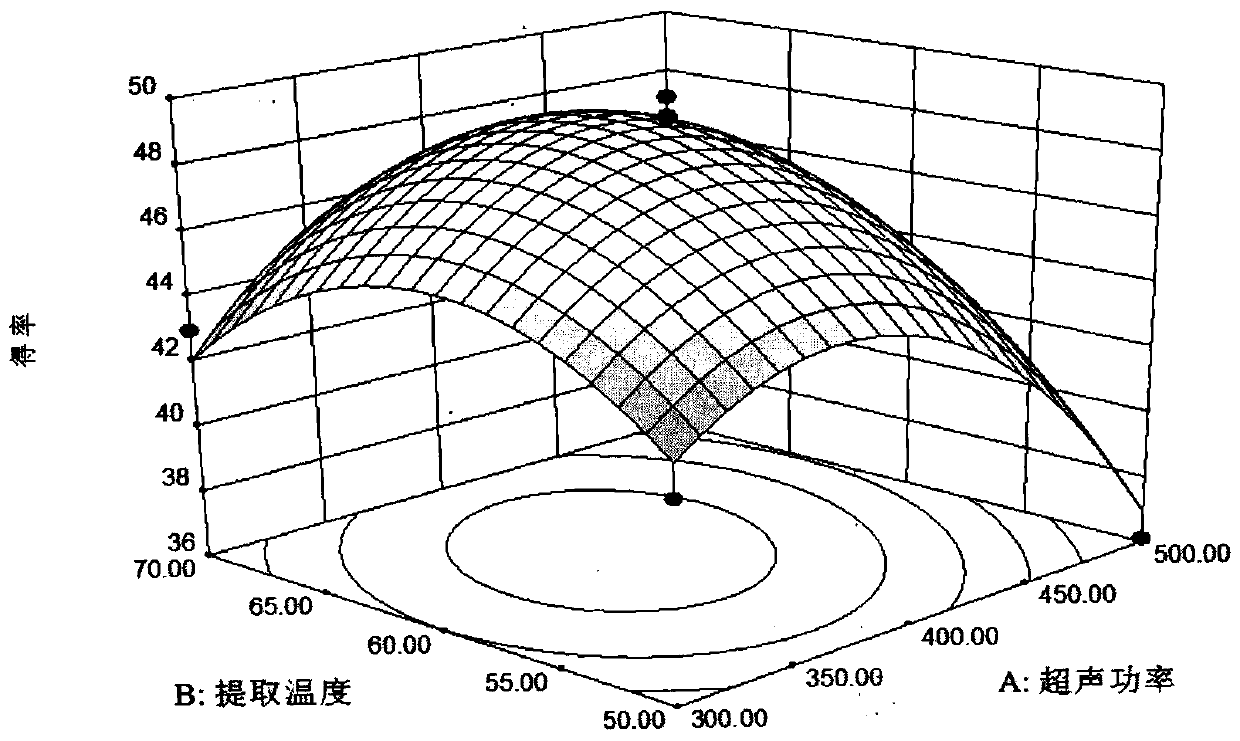

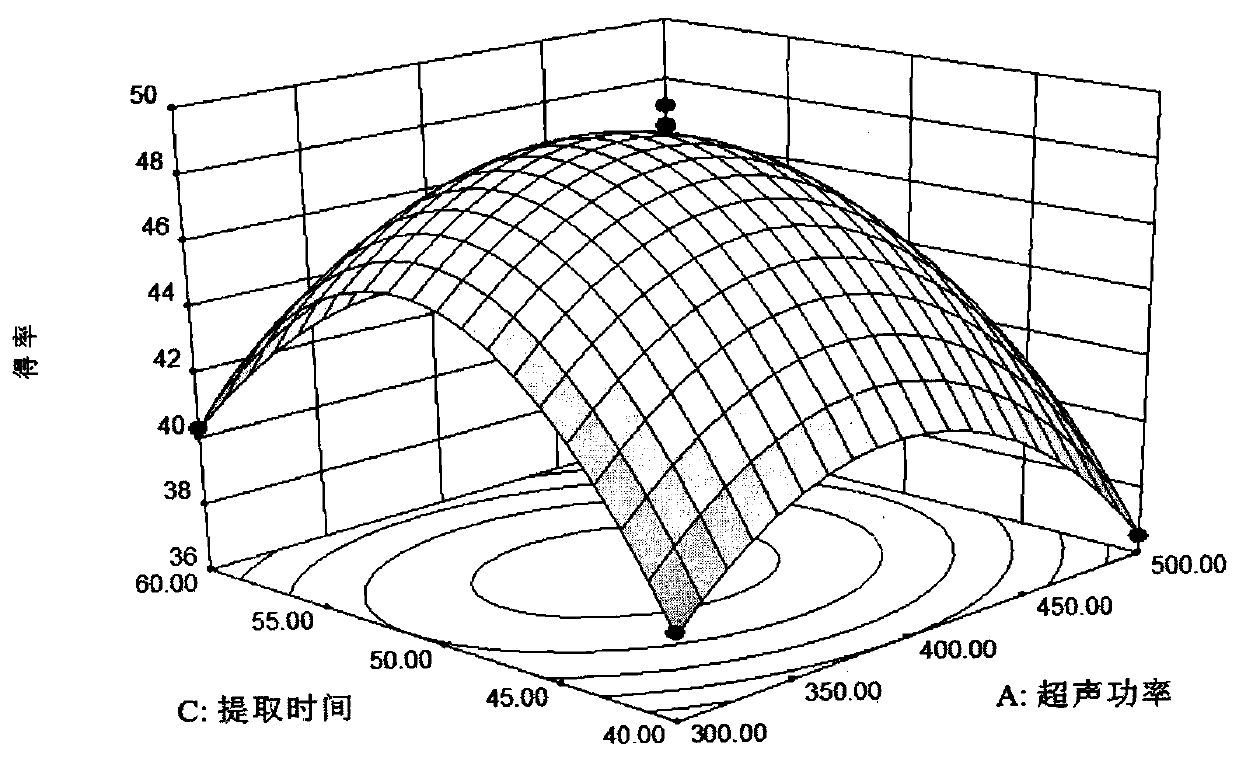

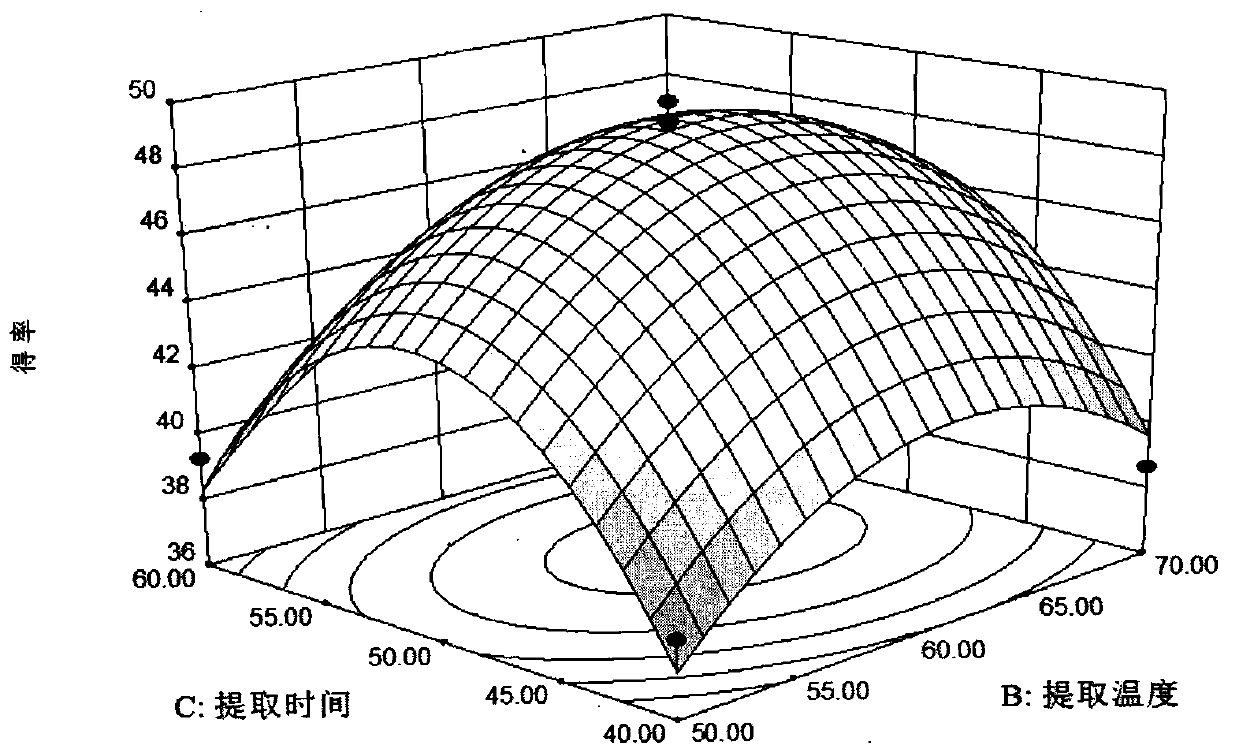

[0027] d. Using Design Expert 8.0.6 software to conduct Box-Behnken design BBD experiments with 3 factors and 3 levels, taking polysaccharide yield as the response value, ultrasonic power 390W, extraction temperature 60°C, total extraction time 50min, 4s off, 4s on Obtain extract under the conditio...

Embodiment 2

[0040] Embodiment 2 (comparison)

[0041] Hot water extraction:

[0042] a. Pulverize the dry products of Zhongyabai and tubers with a pulverizer, pass through a 40-mesh sieve, and store in a ziplock bag at a temperature of 4°C;

[0043] b. Degrease the medium white and coarse powder obtained in step a with petroleum ether Soxhlet reflux for 20 hours at a temperature of 60° C., filter with suction, and evaporate the solvent from the filter residue under flowing air;

[0044] c. Soxhlet reflux with ethanol for 20 hours to remove the pigment and small molecules obtained in step b, and remove the pigment and small molecules, and filter the filter residue under flowing air to volatilize the solvent;

[0045] d. Use a magnetic stirrer to extract the sample obtained in step c for 180 min at an extraction temperature of 100°C and an extraction liquid-to-solid ratio of 40 mg / mL, and use formula 1 to calculate the yield of the extraction liquid;

[0046] e. Centrifuge the Zhong Ya Ba...

Embodiment 3

[0048] The polysaccharide that embodiment 1 and embodiment 2 obtains carries out polysaccharide content and uses phenol-sulfuric acid colorimetric method to measure, and uronic acid content uses m-hydroxybiphenyl colorimetric method to measure, and protein content uses BCA method to measure, and its result is as table 3:

[0049] Table 3 Comparison of ultrasound-assisted extraction optimized by response surface methodology and traditional hot water extraction

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com