A continuous preparation device and method for polyaniline/polypyrrole composite nanofibers

A composite nanofiber and preparation device technology, which is applied in the field of nanocomposite material preparation, can solve the problems of low quality of polyaniline/polypyrrole nanofibers, weakened potential for large-scale application, difficult control of polymerization process, etc., to overcome synthesis efficiency The effect of low pressure, ensuring flow stability and uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

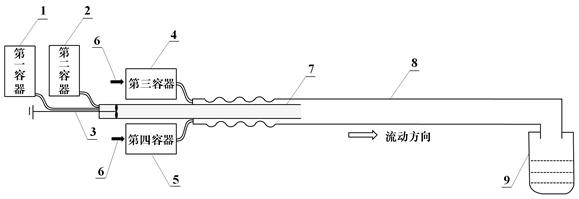

[0031] Such as figure 1 As shown, the continuous preparation device of polyaniline / polypyrrole composite nanofibers of the present invention includes a first container 1, a second container 2, a stirring device 3, a third container 4, a fourth container 5, a flow rate control device 6, a first container A reaction tube 7, a second reaction tube 8 and a collection container 9; the beginning of the first reaction tube 7 is connected to the first container 1 and the second container 2, and its end extends into the second reaction tube in a coaxial manner. In the tube 8, a stirring device 3 is arranged inside; the beginning of the second reaction tube is connected with the third container 4, the fourth container 5 and the first reaction tube 7, and is provided with convex and concave areas. The length of the first described reaction tube is 2 m, and the inner diameter is 20 mm, and the diameter of the stirring device is 18 mm, and the length of the second reaction tube is 2 m, and...

Embodiment 2

[0037] The length of the first reaction tube in the continuous preparation device of the polyaniline / polypyrrole composite nanofiber of the present embodiment is 5 m, and the inner diameter is 30 mm, and the diameter of the stirring device is 28 mm; The length of the reaction tube is 10 m, and the inner diameter is 100 mm; other embodiments are the same as in Example 1.

[0038] Utilize above-mentioned device to prepare the method for polyaniline / polypyrrole composite nanofiber as follows:

[0039] (1) Accurately weigh 4.7 g (0.05 mol) of aniline and 4.1 g (0.025 mol) of ferric chloride, dissolve them in 1 L of 0.3 mol / L mixed dopant solution and inject them into the first container and the second container. In a container, the mixed dopant is composed of phosphoric acid and perchloric acid, the molar ratio of phosphoric acid and perchloric acid is 1:2; accurately weigh 3.4 g (0.05mol) of pyrrole and 4.1 g (0.025mol) of ferric chloride respectively dissolved in 1 L of 0.5 mol...

Embodiment 3

[0044] The length of the first reaction tube in the continuous preparation device of the polyaniline / polypyrrole composite nanofiber of the present embodiment is 5 m, and the inner diameter is 50 mm, and the diameter of the stirring device is 45 mm; The length of the reaction tube is 15 m, and the inner diameter is 150 mm; other embodiments are the same as in Example 1.

[0045] Utilize above-mentioned device to prepare the method for polyaniline / polypyrrole composite nanofiber as follows:

[0046] (1) Accurately weigh 9.3 g (0.1 mol) of aniline and 24.2 g (0.1 mol) of benzoyl peroxide, dissolve them in 1 L of 1.0 mol / L sulfuric acid solution and inject them into the first container and the second container; Accurately weigh 33.6 g (0.5 mol) of pyrrole and 114.1 g (0.5 mol) of ammonium persulfate, dissolve them in 1 L of 1.0 mol / L hydrochloric acid solution, and inject them into the third container and the fourth container.

[0047] (2) Set the rotation speed of the stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com