Preparation method and application of Bi4O5Br2/thin-layer Ti3C2 composite photocatalyst

A photocatalyst, bi4o5br2 technology, applied in the field of nanomaterials, can solve the problems of uniform distribution, agglomeration and inability to catalyze, and achieve the effects of preventing spontaneous collapse and stacking, shortening the diffusion path, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

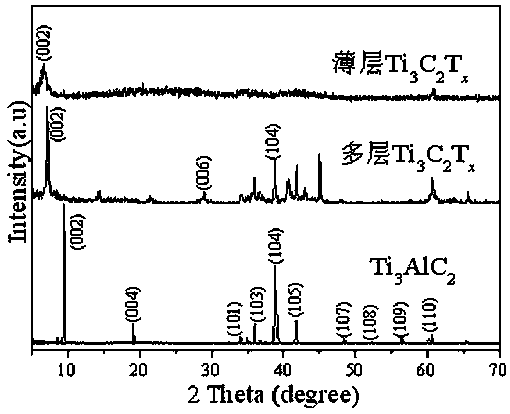

[0033] Slowly add 1 gLiF into 20 mL of 6 M concentrated HCl and stir evenly, then slowly add 1 gTi 3 AlC 2 , continuously stirred at 35°C for 24 h; centrifuged and washed the etched solid until the pH of the supernatant after centrifugation was ≥ 6, collected the solid in a vacuum drying oven, and dried at 60°C for 24 h , the collected solid is the multilayer Ti 3 C 2 material, denoted as multilayer Ti 3 C 2 -A; take 0.2 g multilayer Ti 3 C 2 -A solid was added to 50 mL H 2 In O, sonicate for 1 h under the protection of argon atmosphere, centrifuge at 3500 r / min for 1 h, and collect the dark supernatant as a thin layer of Ti 3 C 2 solution, denoted as thin layer Ti 3 C 2 -A.

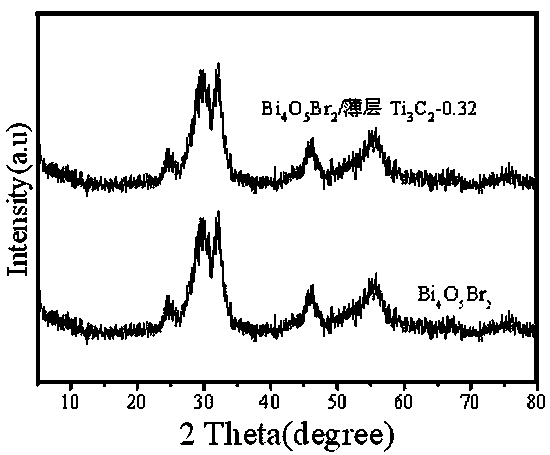

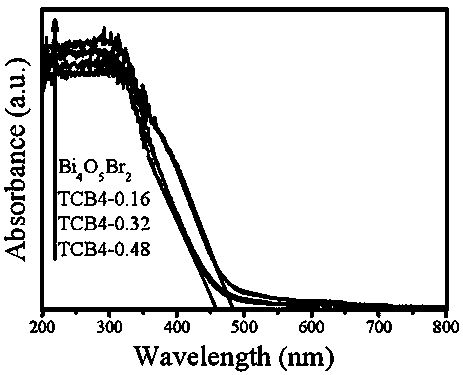

[0034] 0.01 molBi(NO 3 ) 3 ·5H 2 O was added to 40 mL of ethylene glycol and stirred at room temperature for 1.5 h. After clarification, 0.01 mol KBr was added to continue stirring for 0.5 h to form a clear solution A; 4 mL of thin-layer Ti 3 C 2 The solution was diluted to 16 mL with 4 m...

Embodiment 2

[0038] Slowly add 1.5 gLiF into 20 mL of 9 M concentrated HCl and stir evenly, then slowly add 1.5 gTi 3 AlC 2 , continuously stirred at 60°C for 36 h; centrifuged and washed the etched solid until the pH of the supernatant after centrifugation was ≥ 6, collected the solid in a vacuum drying oven, and dried at 60°C for 24 h , the collected solid is the multilayer Ti 3 C 2material, denoted as multilayer Ti 3 C 2 -B; take 0.8 g multilayer Ti 3 C 2 -B solid was added to 100 mL H 2 In O, sonicate for 1 h under the protection of argon atmosphere, centrifuge at 3500 r / min for 1 h, and collect the dark supernatant, which is the thin layer of Ti 3 C 2 solution, denoted as thin layer Ti 3 C 2 -B.

[0039] 0.05 molBi(NO 3 ) 3 ·5H 2 O was added to 40 mL of ethylene glycol and stirred at room temperature for 1.5 h. After clarification, 0.05 mol KBr was added to continue stirring for 0.5 h to form a clear solution A; 3 C 2 The solution was diluted to 16 mL with 4 mL NH 3 •...

Embodiment 3

[0042] Slowly add 2 gLiF into 20 mL of 12 M concentrated HCl and stir evenly, then slowly add 2 gTi 3 AlC 2 , continuously stirred at 60°C for 36 h; centrifuged and washed the etched solid until the pH of the supernatant after centrifugation was ≥ 6, collected the solid in a vacuum drying oven, and dried at 60°C for 24 h , the collected solid is the multilayer Ti 3 C 2 material, denoted as multilayer Ti 3 C 2 -C; take 1.6 g multilayer Ti 3 C 2 -C solid was added to 100 mL H 2 In O, sonicate for 2 h under the protection of argon atmosphere, centrifuge at 3500 r / min for 1 h, and collect the dark supernatant as a thin layer of Ti 3 C 2 solution, denoted as thin layer Ti 3 C 2 -C.

[0043] 0.01 molBi(NO 3 ) 3 ·5H 2 O was added to 40 mL of ethylene glycol and stirred at room temperature for 1.5 h. After clarification, 0.01 mol KBr was added to continue stirring for 0.5 h to form a clear solution A; 12 mL of thin-layer Ti 3 C 2 The solution was diluted to 16 mL with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com