Preparation method of a size-tunable monodisperse nanoporous fe@c core-shell structure

A nanoporous, core-shell structure technology, applied in the field of materials, achieves good application prospects, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Add 1g of PVP powder to a mixed solution of 30mL water and ethanol (V 水 / V 乙醇 =30mL / 0mL), stir evenly to obtain a clear liquid;

[0033] 2) Add 95 mg of ferrous chloride powder into the clarified liquid, stir and dissolve in an ice-water bath for 15 minutes to obtain a light green solution; then pass Ar gas into the solution to exhaust for 15 minutes to prevent Fe 2+ Be oxidized so that the entire reaction system is in an Ar atmosphere;

[0034] 3) 45ml of NaBH4 solution with a concentration of 100mM was added dropwise to the above solution to obtain a black precipitate, which was separated, washed repeatedly, centrifuged, and freeze-dried to obtain a monodisperse Fe sphere powder;

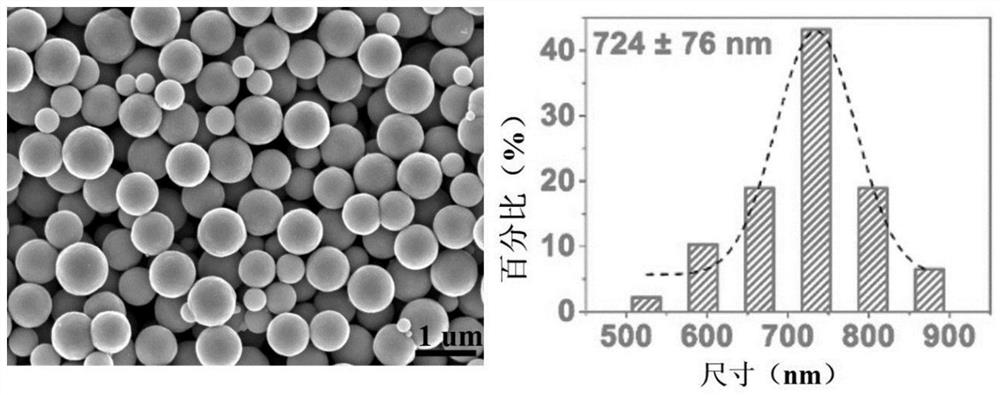

[0035] Embodiment 1 obtains powder appearance such as figure 1 As shown, it can be seen that the morphology of the powder is a monodisperse sphere, and the average particle size is about 724nm.

Embodiment 2

[0037] 1) Add 1g of PVP powder to a mixed solution of 30mL water and ethanol (V 水 / V 乙醇 =22.5mL / 7.5mL), stir evenly to obtain a clear liquid;

[0038] 2) Add 95 mg of ferrous chloride powder into the clarified liquid, stir and dissolve in an ice-water bath for 15 minutes to obtain a light green solution; then pass Ar gas into the solution to exhaust for 15 minutes to prevent Fe 2+ Be oxidized so that the entire reaction system is in an Ar atmosphere;

[0039] 3) adding 45ml of NaBH4 solution with a concentration of 100mM dropwise into the above solution to obtain a black precipitate, which was separated, washed repeatedly, centrifuged, and freeze-dried to obtain a monodisperse Fe powder;

[0040] The appearance of the monodisperse Fe powder that embodiment 2 obtains is as figure 2 As shown, it can be seen that the morphology of the powder is monodisperse spherical, and the average particle size is about 656nm.

Embodiment 3

[0042] 1) Add 1g of PVP powder to a mixed solution of 30mL water and ethanol (V 水 / V 乙醇 =15mL / 15mL), stir evenly to obtain a clear liquid;

[0043] 2) Add 95 mg of ferrous chloride powder into the clarified liquid, stir and dissolve in an ice-water bath for 15 minutes to obtain a light green solution; then pass Ar gas into the solution to exhaust for 15 minutes to prevent Fe 2+ Be oxidized so that the entire reaction system is in an Ar atmosphere;

[0044] 3) adding 45ml of NaBH4 solution with a concentration of 100mM dropwise into the above solution to obtain a black precipitate, which was separated, washed repeatedly, centrifuged, and freeze-dried to obtain a monodisperse Fe powder;

[0045] The morphology of the powder that embodiment 3 obtains is as image 3 As shown, it can be seen that the morphology of the powder is monodisperse spherical, and the average particle size is about 466nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com