Nickel tetrathiocobaltate/cobalt hydroxide nanosheet array structure composite material and preparation and application thereof

A nanosheet array and composite material technology, applied in the field of nanostructured functional materials and electrochemical energy storage, can solve the problem of low energy density of capacitors, achieve high atom utilization, good electrolyte diffusion, and improve specific capacitance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

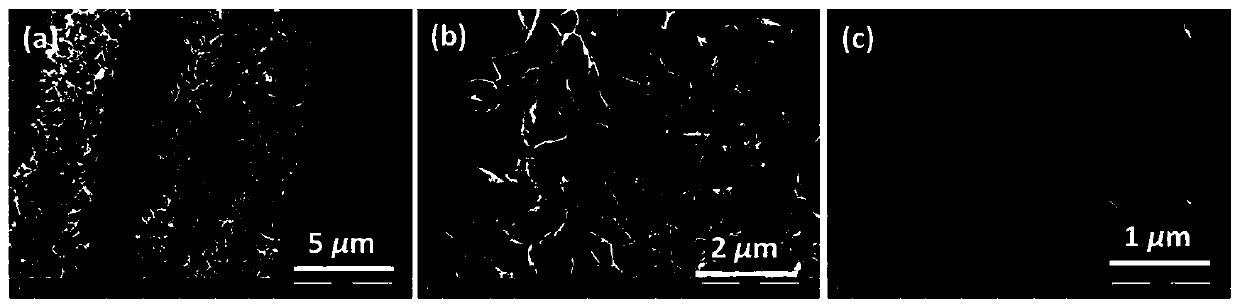

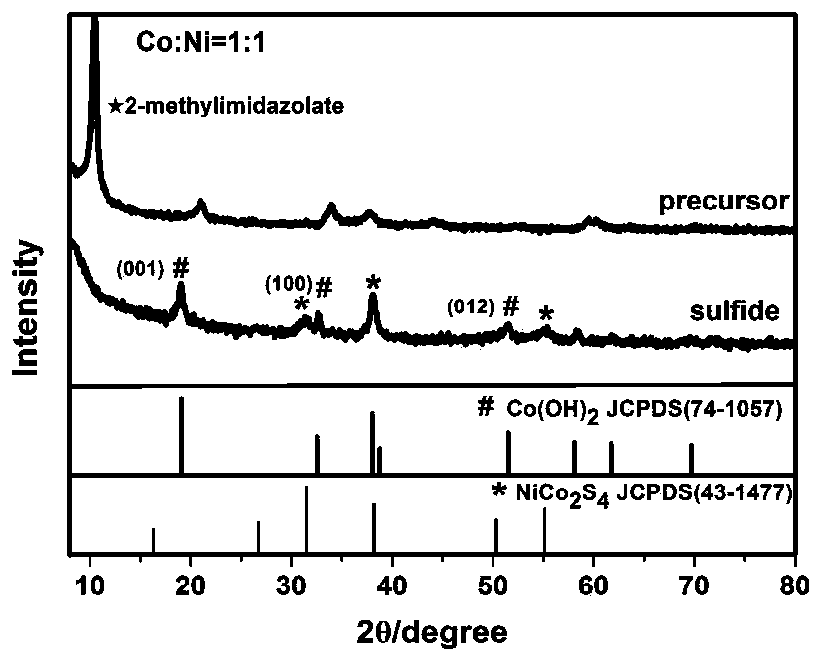

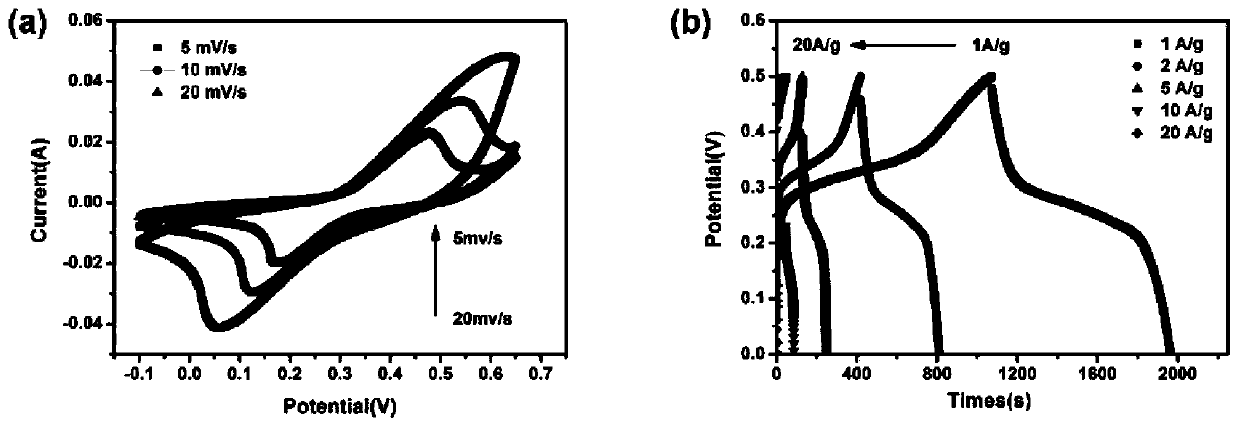

[0039] Example 1: Using carbon cloth as a substrate to prepare NiCo with a nanosheet array structure 2 S 4 / Co(OH) 2 composite material

[0040] (1) Pretreatment of carbon cloth

[0041] Cut into 1cm×4cm carbon cloth, ultrasonically treat in acetone for 30 minutes to remove oily impurities on the surface, and then use 40% HNO 3 Soak for 15 minutes to activate the surface, then wash repeatedly with deionized water, and dry in a vacuum oven at 60°C for later use.

[0042] (2) Synthesis of cobalt-nickel bimetallic organic ligand precursor

[0043] Will Co(NO 3 ) 2 ·6H 2 O(0.72mmol) and Ni(NO 3 ) 2 ·6H 2 O (0.72mmol) was dissolved in 30mL methanol solution to form a clear solution, which was designated as solution A; dimethylimidazole (7.2mmol) was dissolved in 10mL methanol solution, which was designated as solution B. Pour A into B, stir and mix evenly, and transfer to a 50mL polytetrafluoroethylene hydrothermal kettle, put the carbon cloth treated in step (1), and ke...

Embodiment 2

[0051] Example 2: Using graphene as a substrate to prepare NiCo with a nanosheet array structure 2 S 4 / Co(OH) 2 composite material

[0052] (1) Pretreatment of graphene oxide

[0053] Using natural graphite (1g) as a raw material, a graphene oxide solution was prepared by an improved Hummer method, and the obtained graphene was dispersed in 20ml of deionized water for use.

[0054] (2) Synthesis of cobalt-nickel bimetallic organic ligand precursor

[0055] Will Co(NO 3 ) 2 ·6H 2 O(0.4mmol) and Ni(NO 3 ) 2 ·6H 2 O (0.6mmol) was dissolved in 30mL methanol solution to obtain a clear solution, which was designated as solution A; dimethylimidazole (2.4mmol) was dissolved in 10mL methanol solution, which was designated as solution B. Pour A into B, stir and mix evenly, and transfer to a 50mL polytetrafluoroethylene hydrothermal kettle, put the graphene oxide treated in step (1), keep it at a hydrothermal temperature of 120°C for 100min, and obtain a black color after cent...

Embodiment 3

[0065] Example 3: Preparation of Ni with a nanosheet array structure using nickel foam as a substrate 3 S 2 / NiCo 2 S 4 / Co(OH) 2 composite material

[0066] (1) Pretreatment of nickel foam

[0067] Cut into 1cm×4cm nickel foam, ultrasonically treat in acetone for 30 minutes to remove oily impurities on the surface, then soak in 3M HCl for 15 minutes to remove the oxide layer on the surface, then wash repeatedly with deionized water, and dry in an oven at 60°C for later use.

[0068] (2) Synthesis of cobalt-nickel bimetallic organic ligand precursor

[0069] Will Co(NO 3 ) 2 ·6H 2 O(0.4mmol) and Ni(NO 3 ) 2 ·6H 2 O (0.2mmol) was dissolved in 30mL of methanol solution to obtain a clear solution, which was designated as solution A; dimethylimidazole (2.4mmol) was dissolved in 10mL of methanol solution, which was designated as solution B. Pour A into B, stir and mix evenly, and transfer to a 50mL polytetrafluoroethylene hydrothermal kettle, put the foamed nickel sheet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com