Method for achieving ultra-low energy consumption continuous desalting through mixed fluid electrode material

An electrode material and mixed fluid technology, applied in the field of electrochemical desalination, can solve the problems of high performance requirements of electrode materials, high desalination rate, easy to be polluted, etc., and achieve good application value, high desalination efficiency and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

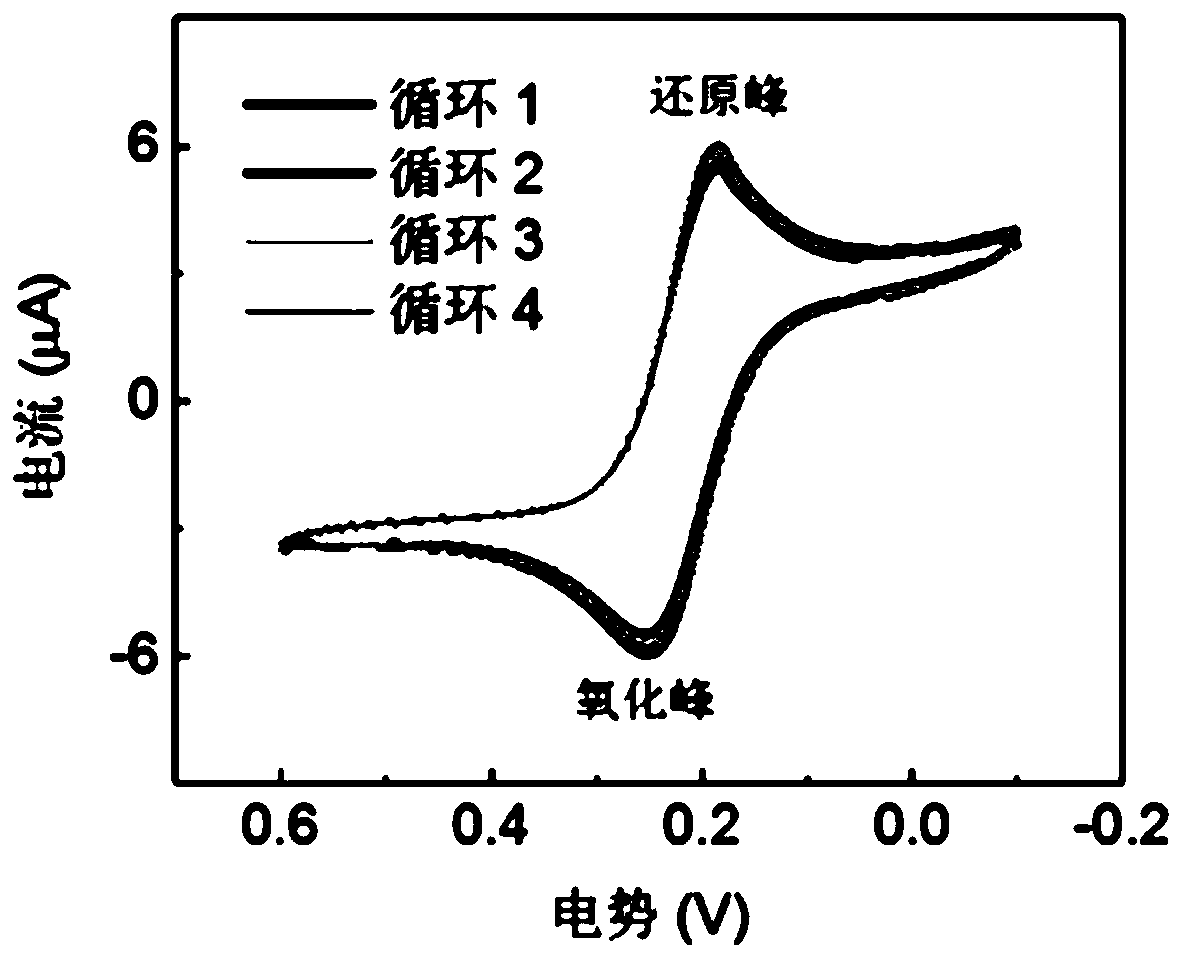

[0045] A method of using mixed fluid electrode materials to achieve continuous desalination with ultra-low energy consumption:

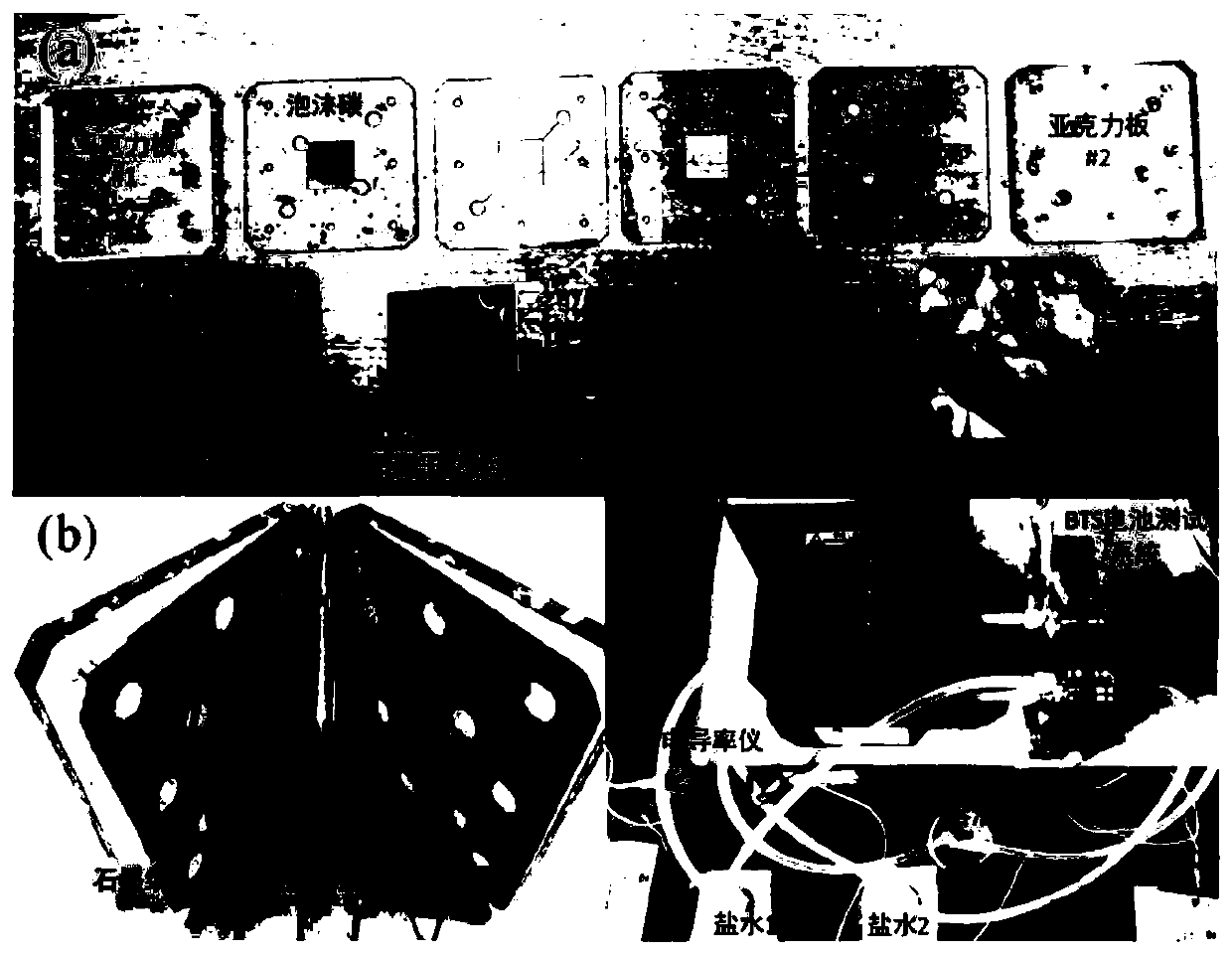

[0046] 1) Cut the graphite paper and anion and cation exchange membranes into a size of 11cm×11cm (consistent with the size of the device mold), and punch a number of holes with a diameter of 1cm on it, so that the screws used to fix the device and the saline solution can smoothly Passed; before assembling the flow battery, the anion and cation exchange membranes were rinsed several times with deionized water, and soaked in deionized water respectively; the graphite paper was ultrasonically cleaned with acetone, alcohol, and deionized water for 10 minutes, and the ultrasonic frequency was 100W. After cleaning, put it in an oven and dry it for use; the screws and joints of the assembled mold are tightly wrapped with raw material tape to prevent water leakage and short circuit;

[0047] 2) Assemble the mold according to the first assembly method, and t...

Embodiment 2

[0054] A method of using mixed fluid electrode materials to achieve continuous desalination with ultra-low energy consumption:

[0055] 1) with the step 1) of embodiment 1);

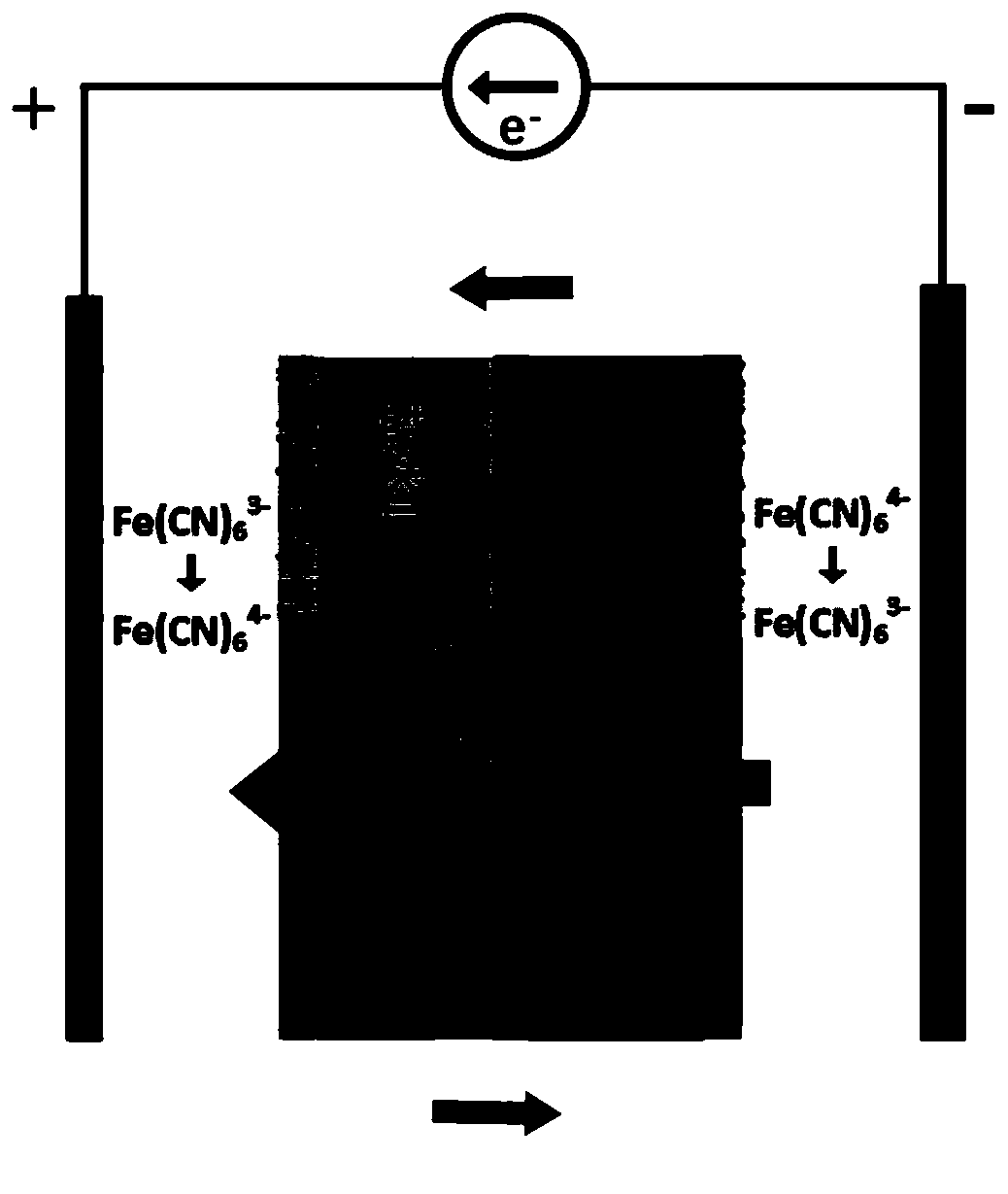

[0056] 2) The mold is assembled according to the second assembly mode, and all the other steps are the same as step 2) of embodiment 1, such as figure 2 Shown is the schematic diagram of the desalination corresponding to the second assembly method;

[0057] 3) Weigh 0.6g NaCl into a 100mL volumetric flask, add deionized water to the scale line of the volumetric flask to obtain a 6g / L NaCl solution; use a graduated cylinder to measure 25mL of the prepared NaCl solution into a beaker as a flow battery saline solution;

[0058] 4) Weigh 0.2112g of potassium ferrocyanide and 0.1646g of potassium ferricyanide into a 100mL beaker, add 50mL of the NaCl solution prepared in step 3) to obtain a mixed fluid electrode material solution with a concentration of 10mM / 10mM; prepare A good mixed fluid electrode mate...

Embodiment 3

[0062] A method of using mixed fluid electrode materials to achieve continuous desalination with ultra-low energy consumption:

[0063] 1) with the step 1) of embodiment 1);

[0064] 2) assemble the mold according to the third assembly mode, and the remaining steps are the same as step 2 of embodiment 1);

[0065] 3) Weigh 1.0g NaCl into a 100mL volumetric flask, add deionized water to the scale line of the volumetric flask to obtain a 10g / L NaCl solution; use a graduated cylinder to measure 25mL of the prepared NaCl solution into a beaker as a flow battery saline solution;

[0066] 4) Weigh 0.4224g of potassium ferrocyanide and 0.3292g of potassium ferricyanide into a 100mL beaker, add 50mL of the NaCl solution prepared in step 3) to obtain a mixed fluid electrode material solution with a concentration of 20mM / 20mM; prepare A good mixed fluid electrode material solution is continuously fed with nitrogen to remove dissolved oxygen in water;

[0067] 5) Before starting the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com